What’s the difference between a motor protection circuit breaker and a thermal overload relay?

Short circuit protection must operate very quickly in the event of a high current, whereas overload protection is typically delayed to allow a motor to draw a higher current while starting. Let’s take a quick look at the difference between the two:

Short circuit protection uses an electro-magnetic mechanism to trip the circuit instantly when the current reaches a certain threshold. It’s generally set to trip at ten or more times the normal motor running current, to avoid tripping during normal motor starting.

Overload (thermal) protection works using a bimetallic strip which bends when heated to a set temperature by the current flowing to the motor. This indicates the motor is continuously drawing excessive current over time – it may be jammed, stalled or under too much load.

Thermal overload relay

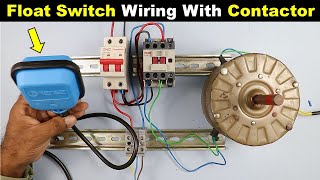

A thermal overload relay, commonly called a ‘thermal overload’, is a device which is usually connected directly to a motor contactor. It offers overload protection only, so must be coupled with an upstream magnetic circuit breaker for short circuit protection. Thermal overloads are generally cost-effective, reliable and simple to install and use so are widely used for motor control.

Motor protection circuit breaker

Also known as a motor circuit breaker, a motor protection circuit breaker is a switchgear device which includes both overload and short circuit protection in a single compact frame. It differs from a standard MCB (miniature circuit breaker) in that it allows the user to preset the exact motor sizing for accurate protection. Motor circuit breakers are very common in industrial motor starting applications.

Electronic motor protection relay

An electronic motor protection relay, or electronic overload relay, is a sophisticated electronic device which uses electronics to continually monitor the motor current and protect against overload scenarios. Most models don’t offer short circuit protection, so must be also coupled with a circuit breaker. A large range of additional communications options are also available, including Ethernet or Serial connections to PLC’s and other automation hardware. An electronic overload offers greater accuracy and flexibility when compared to a standard thermal overload, but is much more expensive. Their use is mostly limited to applications in mining and critical infrastructure where the additional visibility and flexibility is required.

Motor circuit breakers are used for protecting a motor and its supply cable against over-heating by overload. Depending on the overload level, they disconnect the motor from power supply immediately in the case of a short-circuit or they disconnect the motor if an overload has occurred for some time.

Conventional motor circuit breakers are commercially available for various applications with different trigger characteristics (L, G/U, R and K), as shown in the diagram below. As variable frequency drives in most cases are used for supplying motors which are classified as operating equipment with very high starting currents, only the K-characteristic was realized in this function.

Motor circuit breaker

Unlike the operation of a conventional motor circuit breaker which disconnects the equipment to be protected immediately if the trigger threshold is reached, this function provides the possibility of issuing a warning instead of disconnecting the equipment immediately.

The rated values of the VFD are to be considered accordingly when it comes to dimensioning the application. The function of the motor circuit breaker can be linked to different data sets. In this way, it is possible

to operate different motors via one variable frequency drive. Thus, each motor can be equipped with its own motor circuit breaker.

Thermal relays are protective electrical appliances used for overload protection of motors or other electrical equipment and electrical circuits. In the actual operation of the motor, such as dragging the production machinery to work, if the machine is abnormal or the circuit is abnormal, the motor will encounter overload, the motor speed will decrease, the current in the winding will increase, and the winding temperature of the motor will increase. If the overload current is small and the overload time is short, and the motor winding does not exceed the allowable temperature rise, the overload is allowed. However, if the overload time is long and the overload current is large, the temperature rise of the motor winding will exceed the allowable value, aging the motor winding, shortening the service life of the motor, and even burning the motor winding in serious cases. Therefore, this kind of overload is the motor can not bear. Thermal relay is to use the thermal effect principle of current to cut off the motor circuit in case of overload that the motor can not bear, so as to provide overload protection for the motor.

![Overload Relays [Explained - Part 1]](https://i.ytimg.com/vi/Otutc69iGfg/mqdefault.jpg)

Информация по комментариям в разработке