The following points should be noted for American -

1. *Meeting American electrical standards and certification requirements*

**UL Certification**: UL (Underwriters Laboratories) is one of the most well - known electrical safety certification agencies in the United States. In general, transformers need to obtain UL certification to enter the American market, thereby proving that the design, manufacturing, and performance of the products meet strict safety and performance standards. This is the basic requirement of the American market for electrical equipment, and transformers without UL certification are hardly accepted by American customers.

**Adapting to voltage standards**: The voltage standards of the power grid in the United States are different from those of other countries. Common voltages include 480V, 208V, and 120V, etc. American - style transformers exported to Iowa, USA need to be designed and manufactured according to the local voltage requirements to ensure correct voltage conversion. For example, if high - voltage is to be converted into low - voltage suitable for household or commercial use, the transformation ratio of the transformer needs to meet American voltage standards.

2. *Product quality and performance*

**High - efficiency and energy - saving**: In today's environment where energy efficiency is emphasized, high - efficiency and energy - saving transformers are more favored. Products should have the characteristics of low loss and high efficiency, which can reduce energy waste and lower operating costs. This not only meets the needs of the American market but also helps to enhance product competitiveness.

**Good heat dissipation performance**: Heat will be generated when the transformer is in operation. Good heat dissipation performance is crucial for ensuring its normal operation and service life. Especially in some areas of the United States with high summer temperatures, such as Iowa, the transformer needs to have sufficient heat dissipation capacity to prevent overheating and damage.

**Anti - interference ability**: Various electromagnetic interferences may exist in the power grid environment of the United States. The transformer needs to have good anti - interference ability to ensure stable operation in a complex power grid environment without being affected by external interferences.

**Overload capacity**: Considering that there may be short - term overload situations in actual use, the transformer should have a certain overload capacity and be able to withstand loads exceeding the rated power for a short period without immediate damage.

3. *Product structure and appearance design*

**Compact structure**: American - style transformers usually require a compact structure with a small footprint for easy installation and use. Especially in urban areas or places with limited space, a compact structure design can better adapt to the installation environment.

**Beautiful appearance**: Appearance design is also a factor to be considered. The appearance of American - style transformers should be coordinated with the local architectural style and environment in the United States, and aspects such as color and shape need to meet the aesthetic and usage habits of American customers.

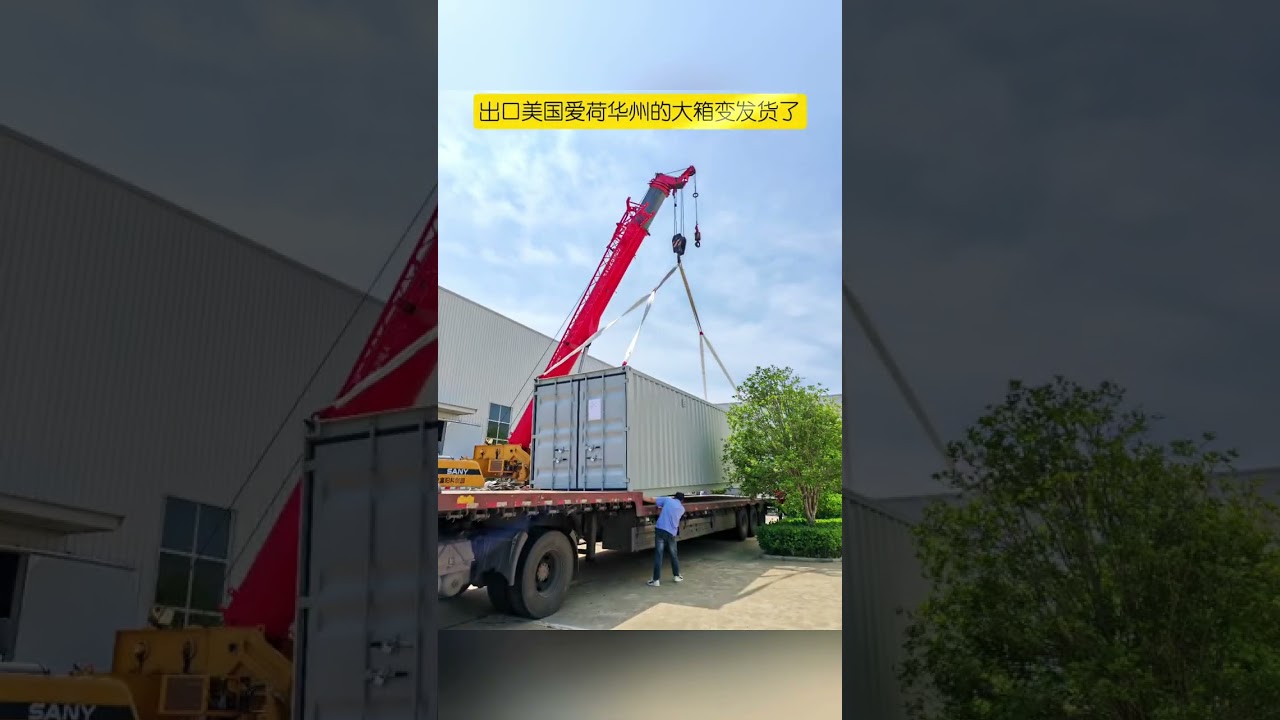

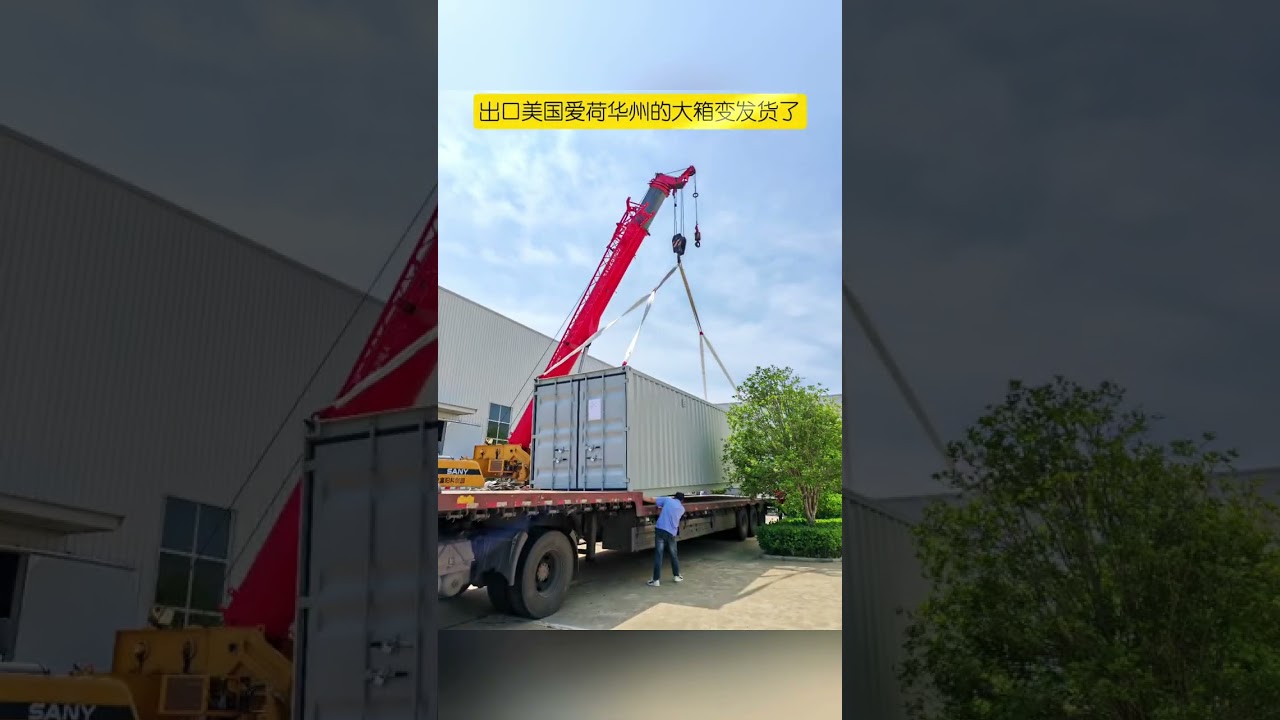

4. *Packaging and transportation*

**Solid packaging**: During transportation, the transformer needs to undergo long - distance transportation and multiple handling operations. Therefore, the packaging must be firm and reliable to protect the product from damage. The packaging materials should have sufficient strength and cushioning performance to prevent the transformer from being affected by collisions, vibrations, etc. during transportation.

**Selecting transportation methods**: Appropriate transportation methods should be selected according to factors such as the quantity, weight, volume, and delivery time of the goods. Common transportation methods include sea transportation, air transportation, and land transportation. For transformers exported to Iowa, USA, sea transportation is usually a more commonly used transportation method. However, if there is a higher requirement for delivery time, air transportation is also an option.

5. *After - sales service*

**Technical support**: Providing timely and professional technical support is an important part of after - sales service. In Iowa, USA, customers may encounter various technical problems, and manufacturers need to respond quickly and provide solutions. Therefore, manufacturers should establish a complete technical support system and equip professional technical personnel to provide timely assistance to customers.

Contact information: Phone: (86) 15611685887

E-mail: [email protected]

WhatsApp & WeCaht:(86)13184948252

WEB:https://skfbearing.com/style-transfor...

Информация по комментариям в разработке