Wood Plastic Composite Wpc Profile Decking Board Extrusion Line Making Machine/PVC WPC Co-Extrusion Decking Machine /WPC Outdoor Floor Production Line/Wood Plastic Composite Flooring Machine/WPC Deck Production Line Composite Decking Machine Wood Plastic Composite WPC Machine Extruder/WPC Wood Profile Production Line Wall Panel Plastic Extruders Wpc Door Making Machine Manufacturing Machine/Decoration WPC Wood Plastic Composite Machine/WPC Profile Board Decking Plastic Extruder Making Machine/WPC Decking Floor Extrusion Line /Pvc Wpc Fencing Profile Production Line Extruder/ Wood-plastic Profile Making Machine/Outdoor PE Wood Plastic Composite Decking Fence Floor Fluted Wall Panel Wpc Extrusion Machine/Wood Plastic Composite WPC PE Decking Fence Extrusion Machinery Profile Extruder Making Machine/3D Embossing Wood Grain Outdoor Wpc Wall Panel Making Extrusion Machine

WPC decking board is made of wood fiber and recycled plastic, the finished products obtained nice appearance of solid wood, also the same touching. It's widely used in: 1) Outdoor project--park flooring, swimming pool decking, outdoor chair, flower boxes,pavilion etc. 2) Yard facility--garden flooring, fencing, log cabin etc. 3) We researched a new item today, injection moulding WPC aterial, which have the characteristic of good liquidity, easy to mold unloading, low price and widely used such as clothes dryer, flower pots, etc. Compared with solid wood, WPC could anti-rot, anti-crack, anti-UV, waterproof, more durable in outdoor life.

1.WPC is obtained PVC PE with natural fibers (such as wood flours coming from rice husk, sugar cane, hemp,…) and some additives.

2.The finished product has a wood like appearance and its main applications are in construction, building exteriors and interiors field (decking, fencing, skirting, panels, wall and ceiling, cladding, door applications).

3.Compared to wood, WPC needs a low maintenance, has a good ageing and heat resistance, weather resistant, fungi free and flame retardant.

4.The WPC market demand is growing worldwide, especially in that countries where the government wants to adopt an Environment Friendly attitude: in fact the WPC polymeric mixture can consist of material coming from industrial scraps or post-consumer waste.

PVC /WPC making machine can produce all kinds of profile, for example, window, door and door frame, pallet, cladding of outdoor wall, facility of outside park, floor etc. Output profile is Wood Plastic Composite(WPC) or Plastic UPVC.

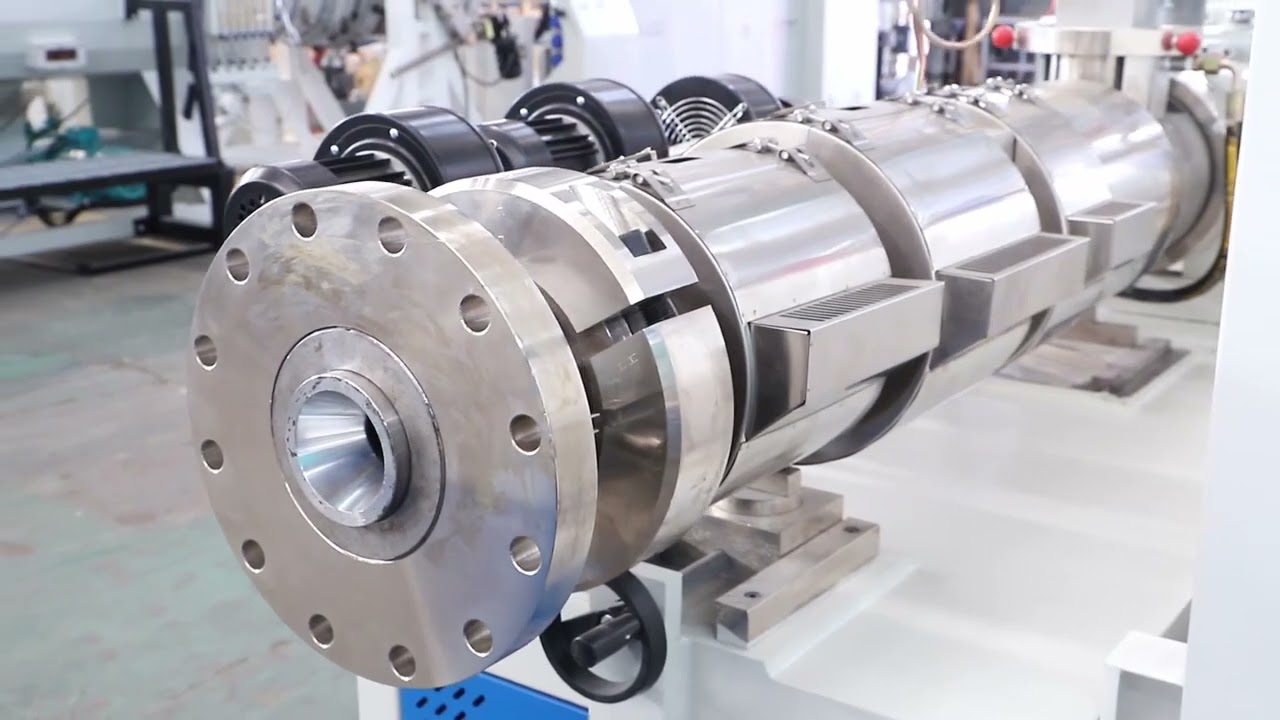

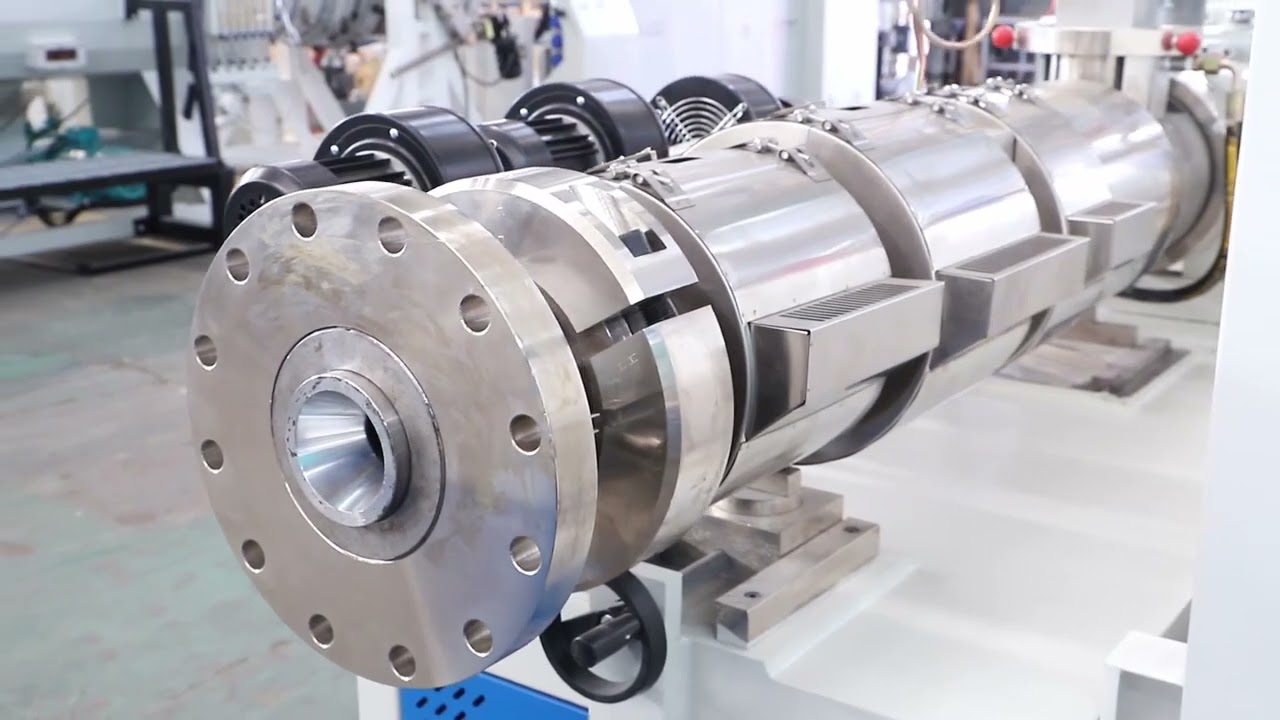

This extrusion machine consists of : Twin conical screw extruder with feeding machine, die head and mould, calibrating table, haul off and cutting units, stacker.

WPC Profile Extrusion LIne

The WPC profile extrusion line can make WPC granules into WPC products by equipping required mold ,we can equip co-extrusion system and online 3D embossing device for making WPC products in hight quality with wooden grain,the line also equipped with online cutting device.

1. SJZ65/132 double screw Extruder

Machine Electrical part:ABB inverter,Electrical wire is CE export standard

Motor :37kw SIEMENS

Gear Box: JC Brand

Control system : Siemens Screen touch control

2.Vacuum Calibration platform

Vacuum calibration table structure adopt 304# Material.There is also table up & down motor and forward & back motor,It is all automatic.It is easy to adjust the mold with Vacuum table. All material what touch with water ,we all use stainless steel.

3.Cutter

Cutting Machine control by PLC,we can cutting by meter.We provide different saw to cut different material products,we also have two kinds of cutter.One is saw cutter,another one is no-dust cutter(cutting by knife).

Most important,we also can confirm some special products cutting accuracy.

4.Stacker

Materials:Stainless steel

Length: 6000mm

Company Name:Zhangjiagang Camel Machinery Co.,ltd

Mobile/Whatsapp/Wechat:0086-19951187015

Email:[email protected]

Информация по комментариям в разработке