See how the Horizon Europe Research Project "BatWoMan" optimizes major steps in lithium-ion battery cell production — from sourcing to the digital battery passport. The animation walks through the improved process chain to achieve substantial reductions in energy use and cost while boosting quality and sustainability, paving the way for European low-emission battery cell manufacturing.

Learn more about the BatWoMan project here: https://batwoman.eu/

Chapters

00:00 Raw Materials — Responsible sourcing of graphite, cobalt sulphate, manganese sulphate, and lithium carbonate to ensure environmental and social sustainability.

00:20 Slurry Mixing — Dry-mixing active material, conductive carbon, binders, and additives, then kneading with solvent into a paste (slurry), filtering and degassing for consistency.

00:42 Coating — Applying the premixed slurry to metal foils (Cu for anodes, Al for cathodes) via slot-die/doctor blade with tight quality monitoring.

01:02 Electrode Drying — Efficient solvent removal (warm air ovens, laser, or hybrid) for mechanical stability and surface quality.

01:23 Calendering — Heated-roll compression to tune thickness, porosity, and density for better adhesion, conductivity, and electrochemical performance.

01:46 Electrode Structuring (3D Electrodes) — Ultra-short pulse lasers create micro-channels for faster ion transport, improved wetting, and extended cycle life.

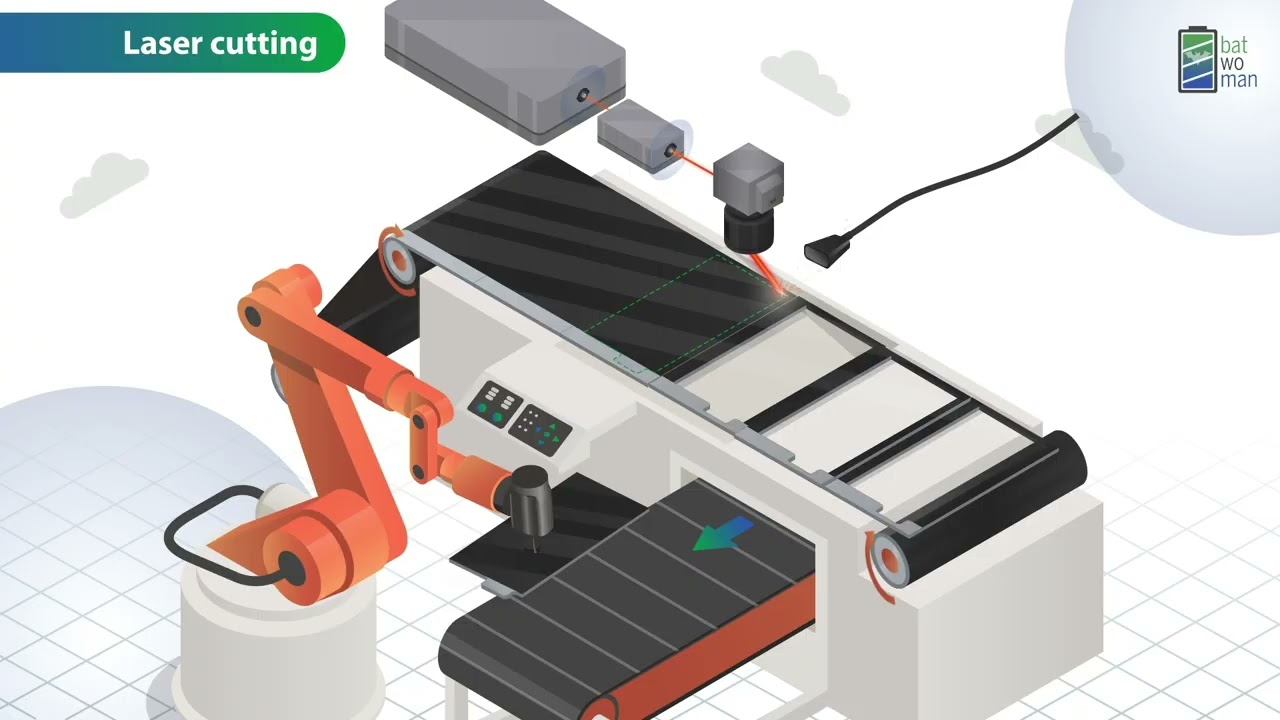

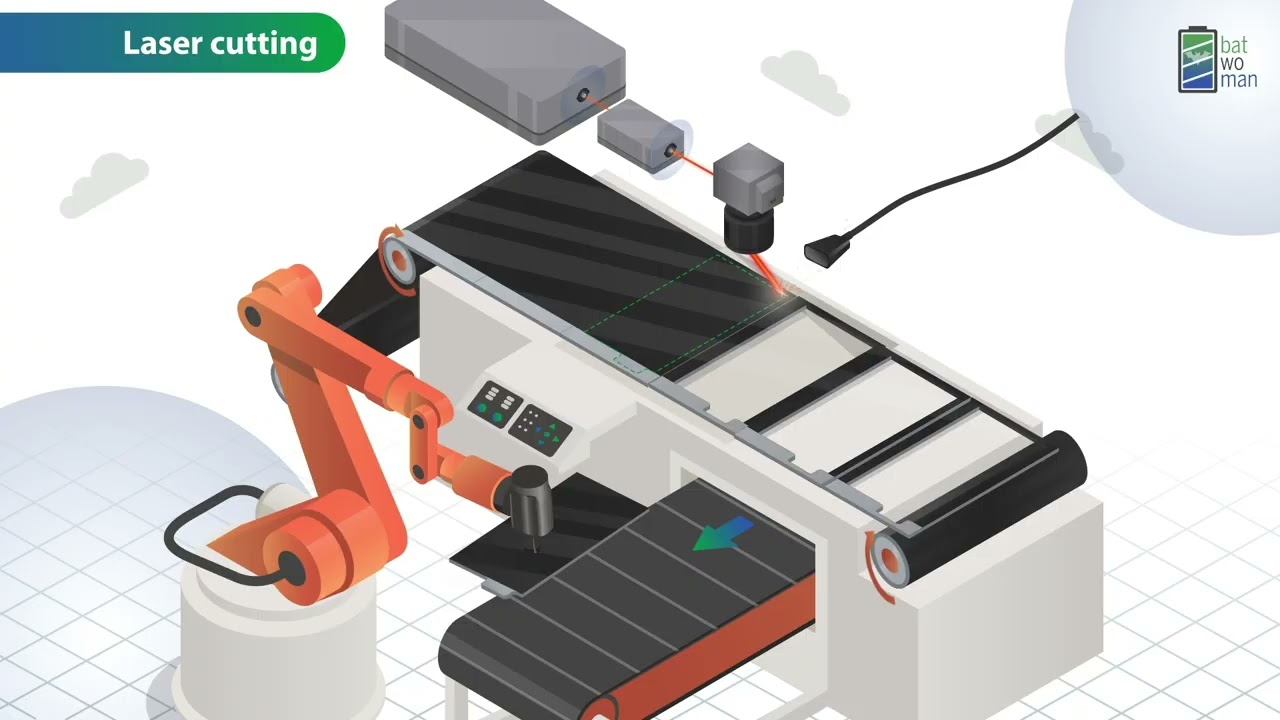

02:16 Die Cutting — Fast, precise mechanical cutting of electrodes into cell-ready shapes.

02:32 Laser Cutting — Contactless alternative for high precision and design flexibility.

03:07 Cell Component Drying — Vacuum/temperature drying of electrodes and separators to prevent moisture-induced performance loss and safety risks.

03:29 Stacking — Accurate layer-by-layer assembly for uniform performance and mechanical stability.

03:46 Electrolyte Filling, Degassing, Sealing — Full wetting, gas removal, and sealing to prepare cells for service.

04:06 Process Optimization & Modelling — Physics-based and AI models to virtually test and tune parameters, saving time and resources.

04:27 Battery Passport — A digital ID capturing materials, processes, carbon footprint, and lifecycle data via a federated dataspace; easy access via QR code.

Why it matters

BatWoMan’s concepts deliver substantial reductions in production energy use and cost, enabling competitive, low-emission European battery manufacturing. The line integrates VOC-free, high-solids slurry processing, laser-assisted drying and 3D laser structuring for faster ion transport, a dry-room reduction approach with improved electrolyte filling, and energy-efficient conditioning (wetting, formation, ageing). End-to-end process modelling and AI drive parameter optimization, while LCA-based eco-design verifies environmental gains. A digital battery dataspace and passport ensures full traceability across materials, processes, and carbon footprint.

Project, Consortium, Credits & Funding

Full project title: Carbon Neutral European Battery Cell Production with Sustainable, Innovative Processes and 3D Electrode Design to Manufacture

Austrian Institute of Technology (AIT): coordination; slurry optimization; assembly/testing; scalable automation

Karlsruhe Institute of Technology (KIT): laser-based 3D manufacturing; roll-to-roll pilots; analysis & spectroscopy

University of Duisburg-Essen (UDE): modelling & simulation; lab validation

RISE: eco-design methodology; LCA

CIDETEC: materials validation; pilot manufacturing; testing

Sovema Group/ANDRITZ: industrial equipment; scaling pathway

Saueressig: calendering with heating unit; inline thickness control

CERTH: electrode microstructure; porosity; CEI/SEI; stack drying

This project has received funding from the European Union’s Horizon Europe research and innovation programme under Grant Agreement no. 101069705, aligned with the EU Battery Regulation and the European Green Deal.

Credits: BatWoMan consortium partners. Animation generation supported by EVA. Die Erklärvideoagentur.

Информация по комментариям в разработке