Forgotten companies: a history by Richard Campbell

The Bucyrus Foundry Company of Bucyrus, Ohio, USA was founded in 1880 and made a range of steel castings and general metal products.

In 1887 they shifted to Milwaukee, Wisconsin to take advantage of the better logistics opportunities this location offered for the distribution of their products and began producing small cranes and steam shovels for industrial use.

Their big break came in 1927 when they merged with the cash-strapped Erie Steam Shovel Company, becoming Bucyrus-Erie.

Before too long, Bucyrus-Erie shovels were becoming preferred equipment on jobsites due to their well thought out design and reliability.

In order to boost their profile in the European market and get around the high taxes and duties British users paid for imported earthmoving equipment, Bucyrus-Erie entered into a manufacturing agreement with the well known and respected UK company of Ruston & Hornsby in 1930, a partnership that was to last for almost fifty years.

UK-manufactured Bucyrus-Erie equipment was marketed as “Ruston-Bucyrus”, and featured engines and some components that were plentiful in the UK and Europe and didn’t have to be imported from the USA.

Bucyrus-Erie were also very conscious of the growing role of the crawler tractor in construction and in the late 1920s, began to design and market a range of complimentary attachments that could be fitted to them.

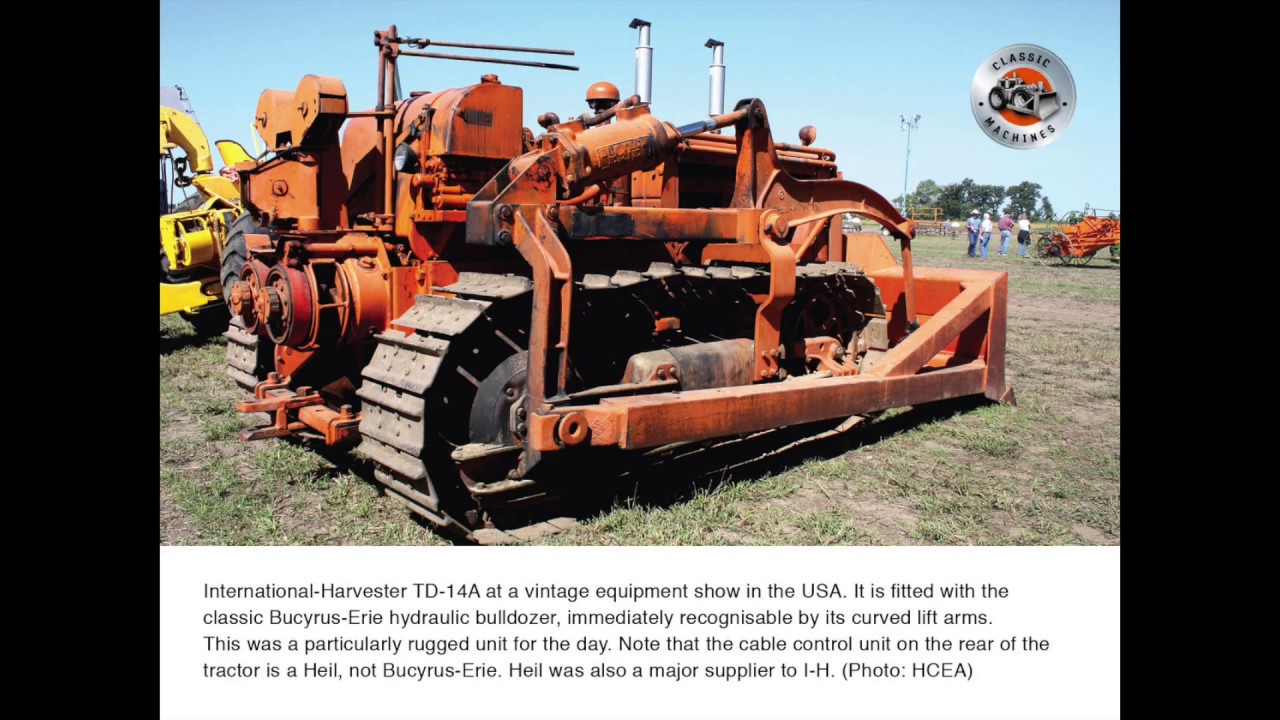

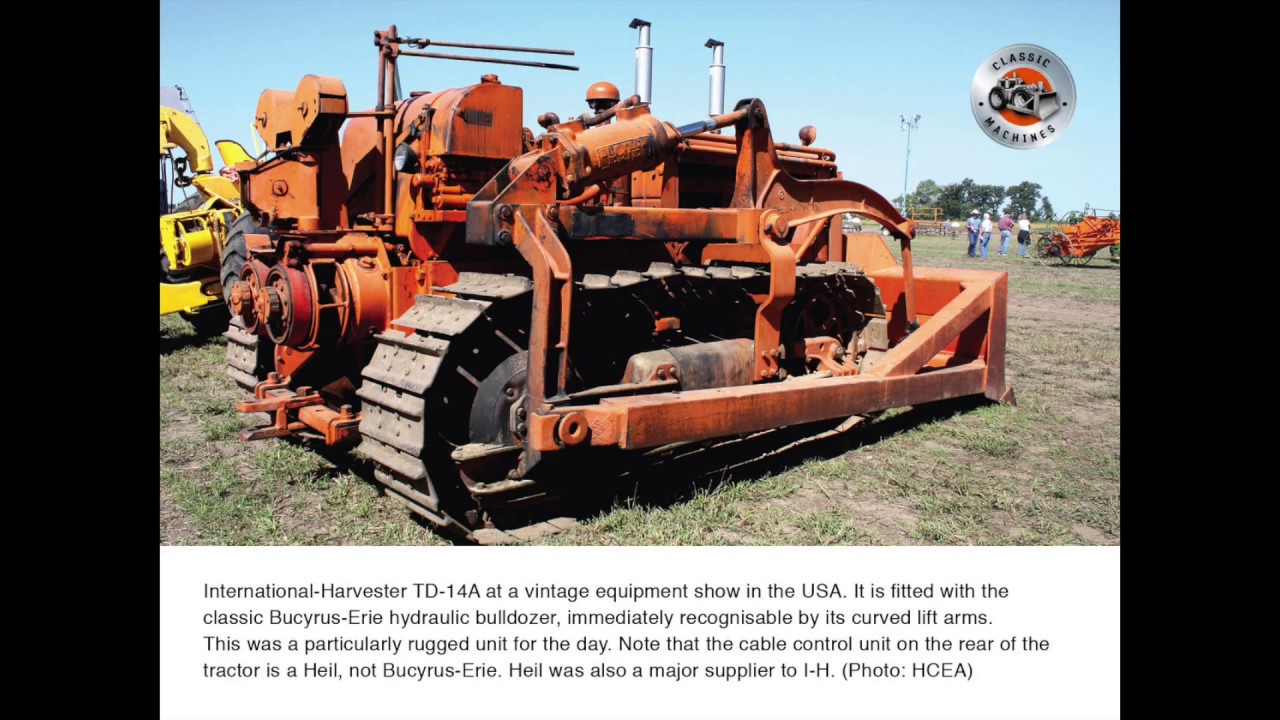

While Bucyrus-Erie products could be fitted to any brand of track type tractor, quite early on in the piece Bucyrus-Erie formed a very close association with McCormick-Deering which in turn was absorbed into International Harvester.

The result was that Bucyrus-Erie became a preferred supplier to that company.

The Products

Bulldozer Blades – Bucyrus-Erie made an extensive range of cable and hydraulically operated blades to fit the entire range of International-Harvester track type tractors.

These were sold under the trade names of Bullgrader and Bulldozer.

Basically, the Bulldozers were an ‘S’ (straight) blade, and the Bullgraders were angle blades which could also be manually adjusted for tilt, a useful feature when cutting trails into a bank.

Both Hydraulic and Cable operated types were manufactured with the hydraulically operated Bullgraders being particularly popular on the small International TD-6, TD-9 and TD-14 tractors.

Bucyrus’ cable operated blades for the TD-18 and smaller I-H tractors were outboard mounted on the track frame and looked somewhat ungainly (similar to LeTourneau’s “speedline” frame.

They had quite a fast cable speed due to the fact that they would only accept a 2-part line and were not particularly popular, most operators preferring the hydraulic variety.

The unit offered for the International TD-24 was far more conventional and robust and could accept up to a four part cable giving very precise control if needed.

Cable Controls

Bucyrus-Erie manufactured their own cable control units (PCU’s) in four different sized models – the P-14, a single drum unit primarily intended for dozer and ripper use, the C-22, a double-drum type designed for small track-type tractors (and not in production for very long) – the P-24, a double drum unit for tractors up to International TD-18 size, and the P-28, also a double drum unit designed for the largest track type tractors of the period.

Due to their open frame construction (apart from the model P-28), they ran cool in operation and were relatively easy to adjust. However the open frame made them susceptible to dust entry and high component wear..

Bucyrus-Erie’s PCU range was sold to Superior Industries not too long after International-Harvester purchased Bucyrus-Erie in 1953.

The Scrapers

Initially, Bucyrus-Erie offered five different sized cable operated scraper models from five to seventeen cubic yards heaped capacity.

They were of a design called a ‘throw-arm’ scraper and differed from conventional scrapers in that the bowl was raised and lowered from the rear and maintained a fairly flat profile throughout all phases of their operation.

The ejector was hinged just behind the cutting edge and was also lifted by cable from the rear, rolling the load out.

Bucyrus-Erie redesigned their entire towed scraper range in 1949, selling the existing S-series patents & jigs to Southwest Manufacturing of Alhambra, California, who continued to manufacture them under their own brand name well into the early 1970s.

These were of a far more conventional design than the previous ‘S’-models but still featured roll-out ejection, which required that the ejector cable be routed over the top of the load, exposing it to wear from dust.

International-Harvester discontinued these scrapers almost immediately after acquiring B-E and they did not reappear under International-Harvester branding.

Bucyrus-Erie scrapers were offered for a short period in the UK by Ruston-Bucyrus and built under licence in Australia by Armstrong-Holland.

Информация по комментариям в разработке