✅ BUY THE VIDEO https://safeti.com/product/workshop-i...

✅ BRAND YOUR INDUCTION https://safeti.com/online-video-induc...

✅ USE FREE COURSE https://safeti.com/courses/workshop-i...

Health and Safety Induction Video for Manufacturing and Workshops - Example

We make bespoke health and safety induction videos for businesses - visit us at https://safeti.com to talk about your Health and Safety induction needs.

Access the full version - https://safeti.com/courses/hs-inducti...

Welcome to your Health and Safety induction for Workshops and Manufacturing sites.

The type of work that we undertake means that thinking about your own health and safety and the health and safety of others must be a priority whilst you are visiting or working on our site.

As a new employee, contractor or visitor to our site, we want to provide you with an overview of the main health and safety arrangements that are in place to ensure you can carry out your work or visit without coming to harm.

We all have a role to play in looking after both ourselves and other site users whilst in the workplace environment, let's take a look at some of common activities that you need to be aware of when visiting the premises.

Entering Site

Upon entering or accessing the site by vehicle, it should be noted that reverse parking is encouraged, this is to reduce the risk of collisions with other vehicles, plant and of course, pedestrians.

Please be aware, heavy plant operates regularly in the production area, including forklifts, work vans, mobile plant and heavy good vehicles (HGV's). It's important that you stay aware of this traffic at all times - ensure to communicate with drivers and banksmen, and wear hi-vis clothing in the designated areas.

Use pedestrian walkways whenever possible and keep an eye out for safety signage across the site.

Production

In the production area, there are various processes that may present significant health and risk. These include, but are not limited to,

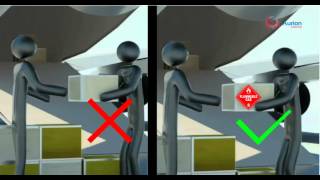

- Manual Handling - this relates to the use of bodily force when moving materials or interacting with machinery. Manual handling should be minimized as far as practicable, mechanical aids and lifting equipment should be used to move materials where possible.

- Machining - The use of machining equipment, including Presses, CNCs, Milling machines, cutting saws and lathes - such type of equipment has significant potential to cause entanglement, crushing, pinching and other serious or fatal injuries

- Pressure Systems - The use of pneumatic and hydraulic pressure systems to process materials - this type of equipment carries the risk of crush, pinch and puncture injury and should only be operated by trained, competent personnel

- Painting - The use of spray booths to provide surface finishes on parts may be in place - these areas have specific controls in place, such as access control, local exhaust ventilation, respirators and coveralls, these areas should only be used by authorized personnel.

- Welding - Different types of welding technique may be used on site to fabricate materials - risks from this activity include harm to respiratory health through the production of welding fume, risk of severe burns due to welding flame and extremely hot materials, alongside risk of eye damage due to welding arc exposure (arc-eye).

Safety devices - Safety devices, such as interlocks, must never be tampered with and any defect should be reported to your line manager immediately.

Информация по комментариям в разработке