https://ginhong.com/high-shear-mixer/...

Ginhong manufactures 0.5hp high shear mixer homogenizer for laboratory use to test making cream, lotion, ointment and gel etc. The mixer was mainly made of a rotor stator work head and a speed controller with 0-6000rpm.

In this video, we put a 30L red bucket under the mixer with water inside. We gradually added carbopol into the water to see how fast it can be dispersed completely.

To learn more about this lab homogenizer, please visit the product webpage here:

What is laboratory batch homogenizer?

JX lab size batch homogenizer, also called lab homogenizer, is a rotor stator mixer for the laboratory of viscous cream and emulsions in the cosmetic, pharmaceutical, food and chemical industries. It’s sometimes used in a multi shaft mixer for homogenization.

What is lab batch homogeniser made of?

JX laboratory top entry batch mixer is usually made one set of rotor and stator, pneumatic or hydraulic lifting system, portable stand, transmission part and motor etc.

How does laboratory top entry batch mixer work?

Due to the pneumatic or hydraulic lifting system, the batch mixer is lifted to its top point so that a portable manufacturing tank can be moved below the mixer. After the tank is fixed by the two brackets around the side, the mixer is brought down inside the tank.

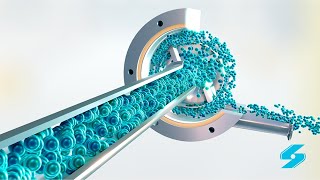

The rotor is driven by ABB or Siemens motor and rotates at the speed of 3000rpm causing strong centrifugal force. The product is sucked from both top and bottom of the rotor into the high shear zone.

The strong centrifugal force drives the product to the narrow gap between the rotor and stator. The product is pressed and crushed by the centrifugal force and then got dispersed, homogenized and emulsified preliminary.

Meanwhile, the rotor produces a linear velocity up to 15~40m/s along the tangent. The product goes through the gap between rotor and stator and is dispersed, high sheared, emulsified and homogenized. Then it jets out from the openings of the stator.

The product jets out from the batch mixer and then goes circulated inside the manufacturing tank. After several circulations, it’s completely high sheared, dispersed, emulsified and homogenized.

Key features of lab batch homogeniser

Complete process of dispersing, high shearing, emulsifying and homogenizing

Working capacity from 0.37kw to 0.75kw

Suitable for cream and emulsions of 20,000~80,000cps viscosity

Suitable for batch process with high efficiency

Pneumatic or hydraulic lifting system for easy cleaning and maintenance

Work with different mixing tanks

All contact parts are made of SS304/316L and mirror polished

The specifications of the top entry batch mixer comply with cGMP regulations

Power supply of 220V, 50Hz, single phase

Technical specifications of laboratory batch homogenizer

Model Motor power (kw) Speed (rpm) Handling Capacity (L)

JX-0.37 0.37 0~6000 0.5~5

JX-0.75 0.75 0~6000 5~15

Applications of lab batch homogenizer

Cosmetics & Toiletries: cream, lotion, wax, mascara, gel

Pharmaceuticals: ointment, dental composite, syrup, injection

Food: mayonnaise, dressing, jam, butter, margarine, wasabi

Chemicals: polyester, synthetic fiber, shoe cream

Options of laboratory batch homogenizer

Different combinations of batch mixer, agitator, high speed disperser and inline mixer for different mixing processes

Atmospheric or vacuum design available for different applications

Interchangeable work heads and screens of slotted and holed designs

Circular and rectangular flange designs for mounting on the vessel

Different pneumatic, hydraulic and electrical lifting devices for lifting the batch mixer for exchangeable tanks

Adjustable brackets for holding the manufacturing tank tightly

Control panel with variable speed drive for adjusting mixing speed

Explosion proof motors and electrics

Different power supply acceptable

Информация по комментариям в разработке