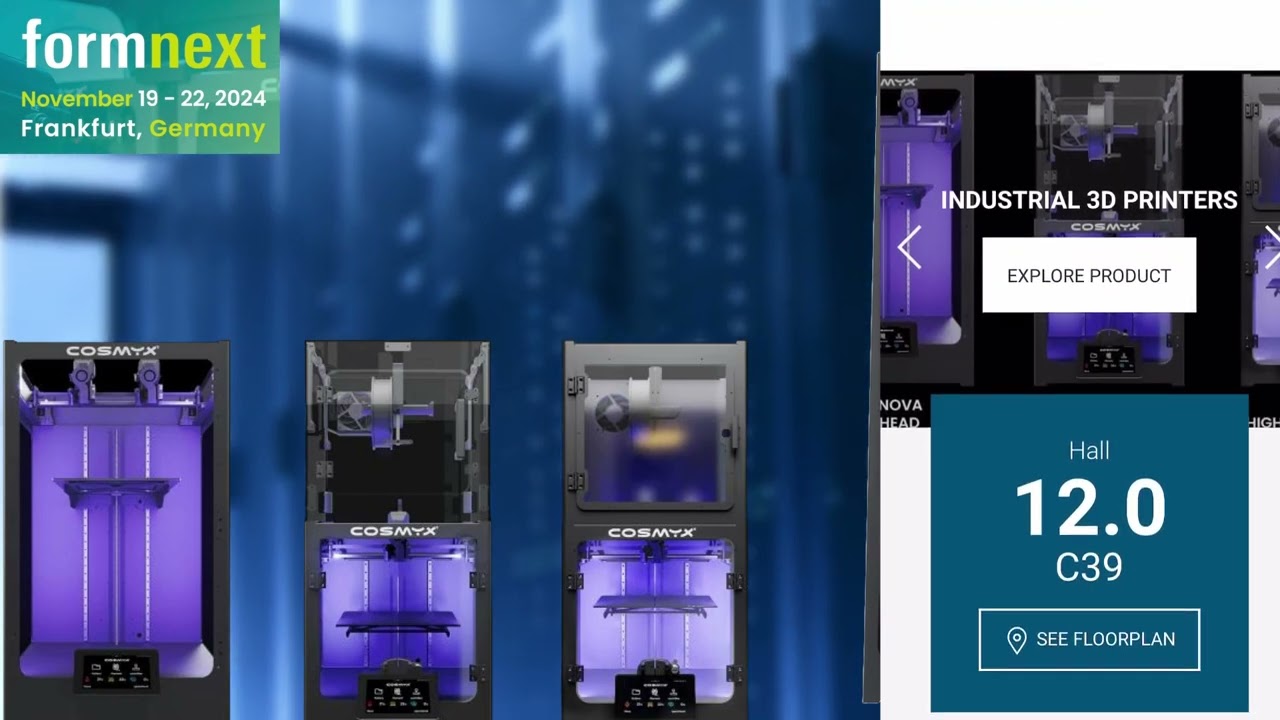

The 𝐅𝐨𝐫𝐦𝐧𝐞𝐱𝐭 exhibition is the ideal platform to showcase Cosmyx’s advanced 3D solutions, integrating groundbreaking technologies and smart automation systems that significantly enhance the efficiency, precision, and scalability of additive manufacturing processes.

Our 𝐒𝐔𝐏𝐄𝐑 𝐍𝐎𝐕𝐀 𝐃𝐔𝐀𝐋-𝐇𝐄𝐀𝐃 printer is pushing the boundaries of large-format industrial 3D printing. With dual extrusion capabilities, it enables simultaneous deposition of two different materials or colors, expanding the range of applications, particularly for high-strength parts, multi-materials, or complex geometries. This system leverages advanced thermal management and precise control of the printing environment, crucial for maintaining the mechanical integrity of printed components, especially for load-bearing structures where residual stress and thermal expansion need to be minimized. This printer integrates key mechanics principles, from the control of stress distributions to material flow, allowing for high-fidelity prints with superior dimensional accuracy.

Next in our product lineup is the 𝐌𝐈𝐑𝐀 automated micro-factory. MIRA revolutionizes the end-to-end production process by automating the critical step of part ejection, reducing downtime and enhancing throughput. In high-stakes industrial environments, minimizing operator intervention and automating repetitive tasks is vital for optimizing production rates. MIRA’s automatic ejection system is engineered using high-torque actuators and precise motion control algorithms, which ensure that the finished part is smoothly and safely removed without damaging its delicate surface features or compromising its structural integrity. This system is particularly beneficial in precision mechanics, where dimensional tolerance is key, and every minute saved in production translates to tangible cost reductions.

MIRA’s robotic version, integrated with a Fanuc robot, demonstrates our commitment to seamless automation. The robot’s role in unloading printing plates enhances the workflow in additive manufacturing environments, where efficiency in transitioning between production phases is critical. The robotics component relies on the mechanics of kinematics and dynamics, ensuring the safe manipulation of printed objects and accurate placement in post-processing systems. The fluidity of this process exemplifies the integration of mechanics, robotics, and automation to streamline manufacturing.

The 𝐍𝐎𝐕𝐀 printer, featuring MainChain, Vistory’s data security software, addresses a crucial concern in today’s connected manufacturing environments—data integrity. With manufacturing systems increasingly networked, ensuring the security of design files, machine data, and production parameters becomes paramount. MainChain uses blockchain technology to protect sensitive data, providing immutable records of the manufacturing process and enhancing traceability, which is essential for highly regulated industries such as aerospace, defense, and healthcare.

Our partnership with Nanoe brings cutting-edge material science to the forefront of 3D printing. The 𝐍𝐎𝐕𝐀 𝐌𝐄𝐓𝐀𝐋 𝐀𝐍𝐃 𝐂𝐄𝐑𝐀𝐌𝐈𝐂𝐒 printer, on display at Nanoe’s booth, demonstrates our capability to print high-performance parts using innovative ceramic and metal materials. Ceramic 3D printing opens new horizons for applications requiring exceptional thermal stability, wear resistance, and chemical inertness, while metal printing enhances mechanical strength and durability. The combination of these materials in additive manufacturing pushes the limits of design and production, allowing for parts that would be impossible to create using traditional methods.

Finally, we invite you to explore the 𝐍𝐄𝐗𝐔𝐒 modular 3D micro-factory, presented in collaboration with our partner Tectonic-3D. NEXUS epitomizes the future of distributed manufacturing, combining flexible design with scalable production capabilities. Its modularity allows for custom configurations tailored to specific industry needs, enabling rapid deployment and real-time production closer to the point of use. This is particularly impactful in remote locations or in industries such as aerospace and defense, where on-demand manufacturing can save critical time and resources.

We look forward to welcoming you at Formnext, where Cosmyx and Vistory will be presenting at booth C39 in Hall 12.0, Nanoe at C31 in Hall 12.0, and Tectonic-3D at C39 in Hall 12.1. Discover how we are driving the future of additive manufacturing with precision, innovation, and sustainable solutions.

#Formnext2024 #AdditiveManufacturing #3DPrinting #Automation #MaterialScience #DigitalTransformation

Информация по комментариям в разработке