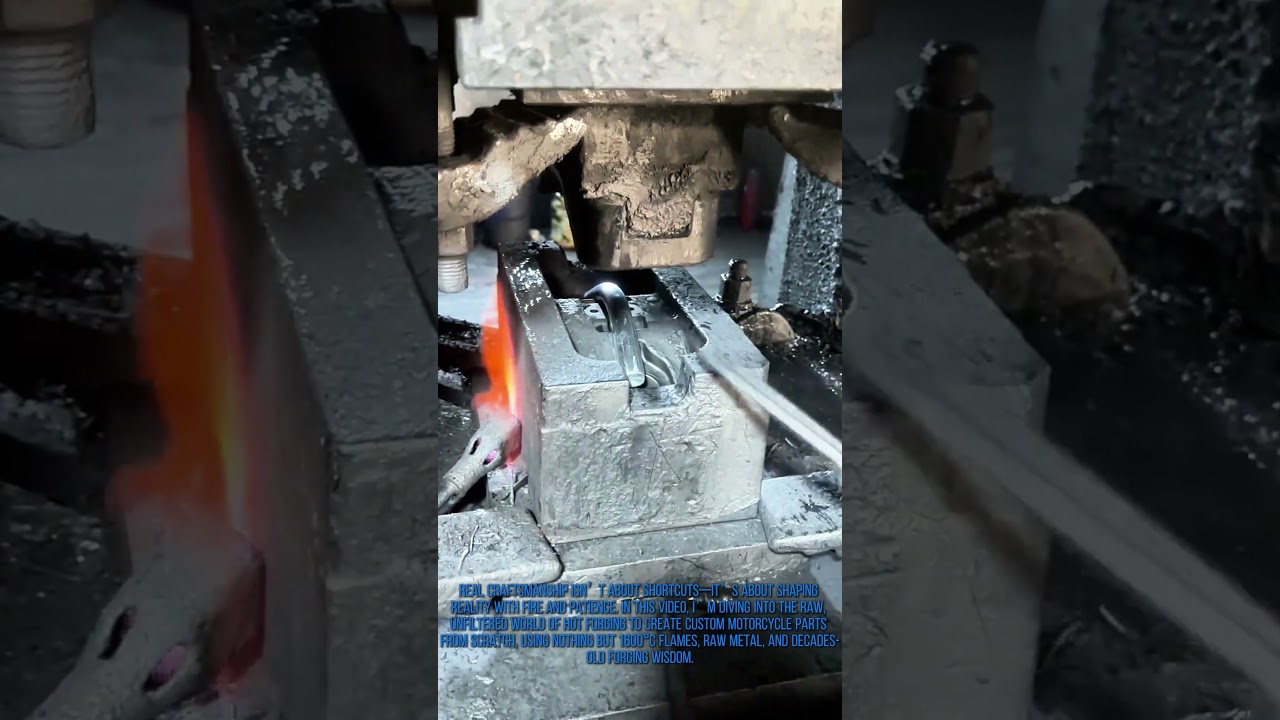

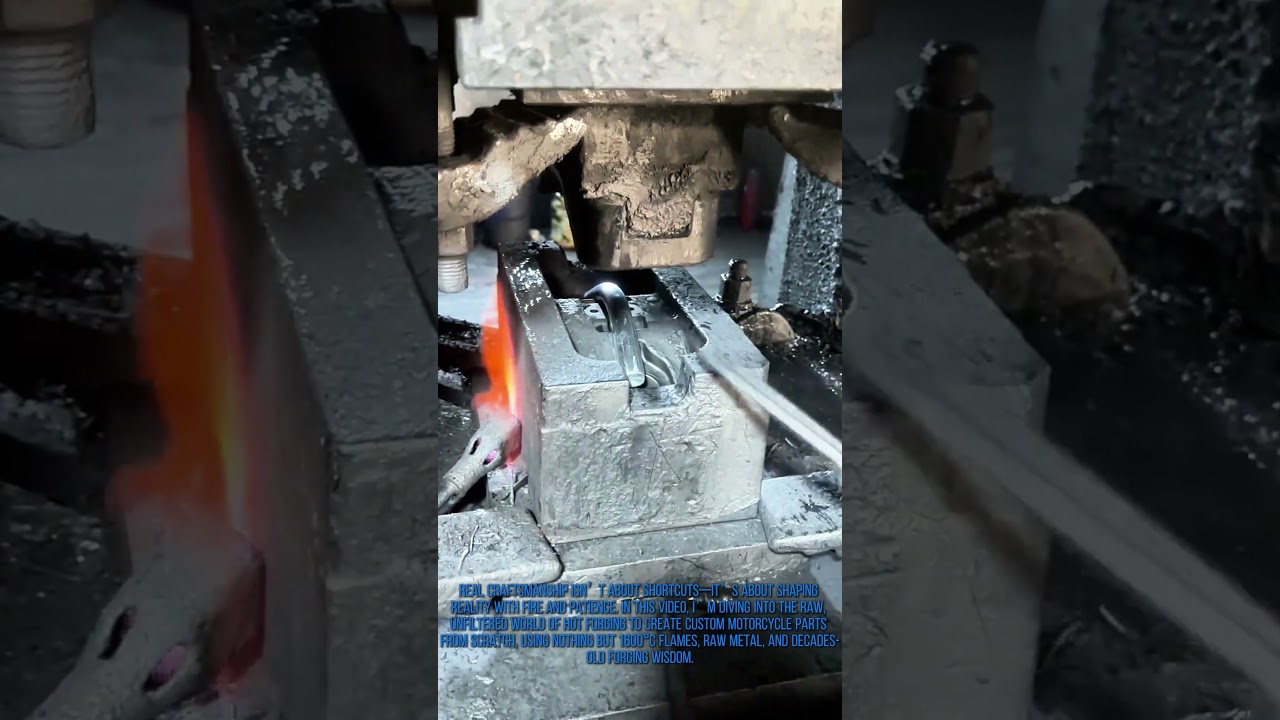

Real craftsmanship isn’t about shortcuts—it’s about shaping reality with fire and patience. In this video, I’m diving into the raw, unfiltered world of hot forging to create custom motorcycle parts from scratch, using nothing but 1600°C flames, raw metal, and decades-old forging wisdom.

The process starts with selecting a high-carbon steel billet, a material chosen for its ability to transform under intense heat. I load it into a coal forge, where flames dance around it until the surface glows a fiery orange-yellow—a sign that the metal has reached a malleable state, where its atomic structure softens enough to bend without cracking. Wearing thick leather gloves and a face shield (safety first!), I use a 20-pound power hammer to pound the heated billet, compressing its molecules and shaping it over a custom-built mold. Each strike echoes through the workshop, a rhythmic battle between human strength and metal’s natural resistance.

Why go through this labor-intensive process? Because hot forging isn’t just about making parts—it’s about improving them. Unlike mass-produced components, forged pieces have a uniform grain structure that’s denser and stronger, reducing weak points and extending the life of your bike. I’m crafting a custom brake caliper bracket here, designed to fit my vintage motorcycle perfectly while shaving off extra weight. The key principle here is leveraging heat to enhance material properties: when metal is heated above its recrystallization temperature, stress fractures disappear, and the result is a part that can handle more stress than its factory-made counterpart.

But it’s not all smooth swings and sparks. I’ll show you the trial and error—like when the first few attempts warped because I didn’t cool the metal evenly, or how adjusting the hammer’s pressure mid-strike changed the final shape. This isn’t a perfect science; it’s a craft that rewards attention to detail. By the end of the video, you’ll see the raw billet transform into a functional, gleaming part ready to be installed, with every hammer mark a testament to its handmade story.

For those looking to try this at home, safety can’t be overstated. Always use proper PPE: heat-resistant gloves, a full-face shield, and a welding apron. Keep a fire extinguisher nearby, and never work alone—metalworking accidents happen fast. If you’re new to forging, start with smaller projects before tackling motorcycle parts, and invest in a temperature gauge to monitor the forge’s heat (those flames are hotter than they look!).

This project matters because it brings back the value of making things ourselves. In a world of disposable parts and mass production, forging connects us to a tradition where every object has a story and a purpose. It’s not just about saving money (though custom parts often outlast store-bought ones); it’s about understanding the materials we work with, and respecting the power of fire—both to create and to destroy, if we’re not careful.

As I finish the bracket and test its fit, I’m reminded that true DIY isn’t about perfection. It’s about showing up, learning from mistakes, and turning raw materials into something useful. So grab your gloves, heat up your forge, and let’s celebrate the art of making things by hand—because there’s no substitute for the satisfaction of holding a part you built with your own two hands, forged by fire and shaped by will.

Информация по комментариям в разработке