Welcome to Sahil CNC Machines — India’s trusted OEM for high-precision CNC Turning, Milling, Boring, and Vertical Turning solutions. Since 1965, Sahil Machines has delivered industrial-grade CNC machines designed for the most demanding manufacturing environments. With a focus on indigenous design, in-house foundry support, and ISO-compliant quality control, Sahil Machines is a name synonymous with precision and reliability.

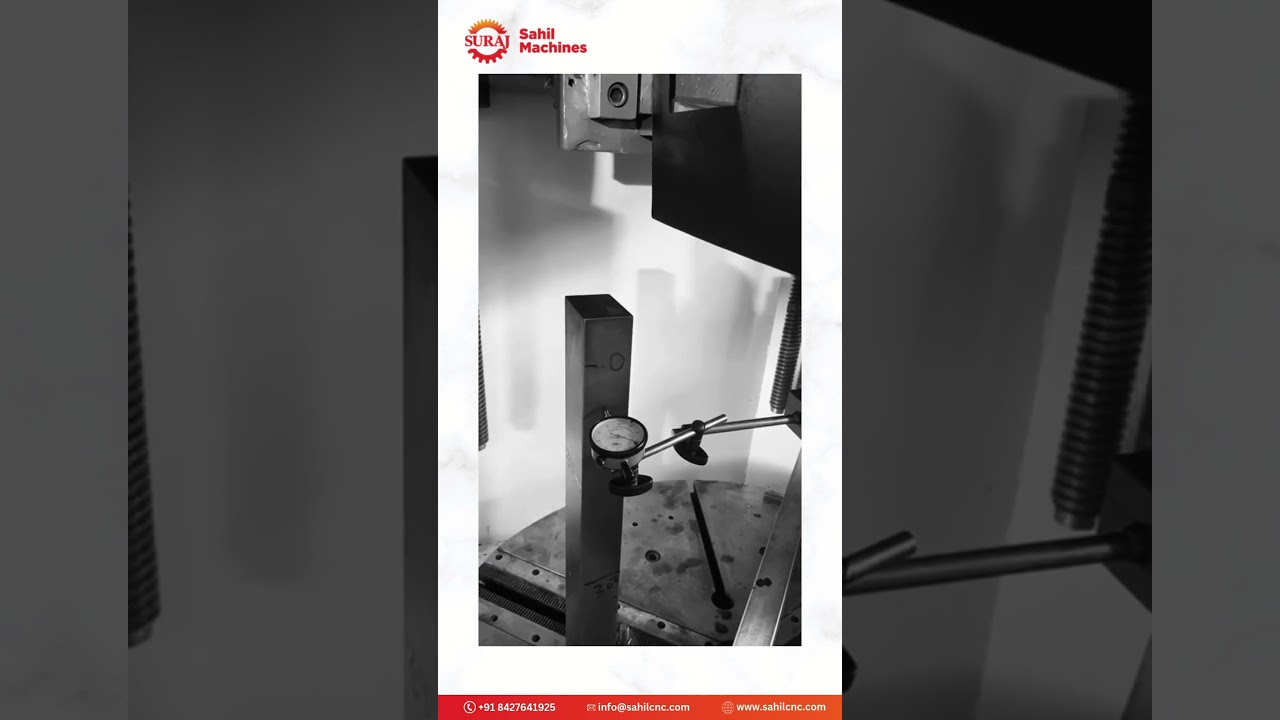

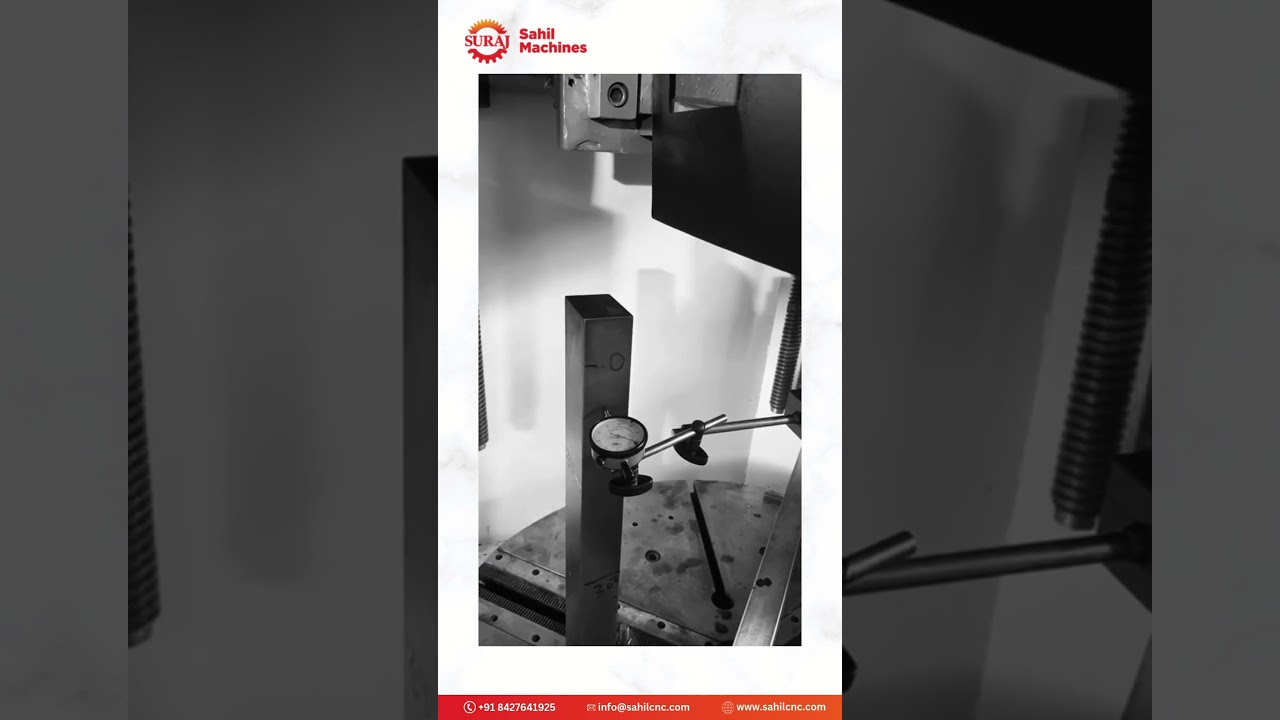

In this video, we showcase the CNC VTL 1500 from our Suraj Series, undergoing a 10-micron Z-Axis perpendicularity accuracy test. This demonstration highlights our rigorous in-house testing standards to ensure every machine complies with Indian Standard (IS) parameters for straightness, perpendicularity, and repeatability.

Test Overview – CNC VTL 1500 Z-Axis Accuracy & Perpendicularity

• Z-Axis Perpendicularity: Achieved within 10 microns (0.010 mm)

• Reference Standard: As per ISO 230-2 and Indian Standard IS 2062

• Inspection Tooling: Dial gauge, square master, granite base, and calibration fixtures

• Measuring Method: Tool turret movement measured against flat reference over entire Z travel

• Repeatability Check: Backlash compensation and thermal drift minimized during testing

Why Z-Axis Accuracy Matters in CNC VTLs

• Flat Surface Finishing – Ensures perpendicularity between tool path and job surface

• Flange and Face Machining – Maintains tolerances across diameter and axial height

• Tool Life and Consistency – Reduced tool deflection and better wear distribution

Machine Overview – CNC VTL 1500 (Suraj Series)

• Max Swing Diameter: 1600 mm

• Max Turning Diameter: 1500 mm

• Spindle Power: 37 kW high-torque motor

• Bed & Column: FG-300 grade castings with stress-relieved and FEA-validated structure

• Tool Turret: 8/12-position vertical turret with optional live tooling

• CNC Control: Siemens 828D or Fanuc 0i TF

• X/Z Axis Drive: Servo motor with LM/box guideways for rigid movement

• Workholding: Hydraulic chuck (optional 4-jaw independent/manual options)

• Coolant System: Integrated high-flow coolant with optional through-tool cooling

• Accuracy Standards: ISO 230-2, IS 2062, VDI 3441

Key Features of CNC VTL 1500

• High-Precision Turning – Engineered for micron-level contouring and flatness

• Heavy-Duty Build – Massive structure ensures vibration-free operation even under full load

• Flexible Tooling – Supports boring bars, drills, OD/ID tools, and live tools

• Process Reliability – Tested across thermal cycles and under continuous load

• Multi-Industry Compatibility – Aerospace, hydro turbines, power plants, railways, shipbuilding

Applications – Where CNC VTL 1500 Delivers Value

• Aerospace and Defense – Machining large rings, casings, propulsion system parts

• Power Generation – Turbine hubs, stator covers, flange rings

• Oil and Gas – Valve seats, pump casings, flanges, adaptors

• Heavy Engineering – Crusher parts, bearing housings, machine bases

Why Choose Sahil Machines

• OEM Manufacturer Since 1965 – Proven supplier to BHEL, BEML, HAL, ONGC, DRDO, Indian Railways

• In-House Foundry – FG-300 castings made internally for machine beds, turrets, columns

• Full IS and ISO Compliance – From casting to assembly, all processes are standards-driven

• Atmanirbhar Bharat Certified – Proudly made in India with global benchmarks

• Quality Control – Accuracy charts, runout reports, test cycles included in every dispatch

Explore More Sahil VTL Solutions

• VTL Product Overview: https://www.sahilcnc.com/turning-mach...

• CNC VTL 1500 Product Page: https://www.sahilcnc.com/turning-mach...

• WhatsApp Enquiry: https://wa.me/918427641925

• Website: https://www.sahilcnc.com

• Email: [email protected]

• YouTube Channel: / @sahilcncmachines

Sahil Machines is an industry-leading Indian OEM that integrates precision casting, machine design, CNC engineering, and after-sales support into one unified workflow. All Sahil machines are IS-compliant and designed to deliver long-term performance in real-world industrial conditions. With CNC VTLs like the VTL 1500, Sahil proves that world-class precision and structural performance can be achieved from within India — strengthening Make in India and industrial self-reliance.

CNC VTL 1500 Accuracy Test, Z Axis Perpendicularity Test India, 10 Micron Accuracy CNC Lathe, Sahil CNC Machines, IS Standards CNC Machine, Vertical Turning Lathe India, CNC VTL Manufacturer India, Heavy Duty Vertical Lathe, CNC Lathe with ISO 230-2 Accuracy, Atmanirbhar Bharat Machines, Indian OEM CNC VTL, VTL for Power Plants, Railway Flange Machining VTL

#cncvtl #vtl #zaxis #accuracy #sahilmachines #isstandards #madeinindia #atmanirbharbharat #precisionmachining #heavymachining #suraj #engineeringexcellence #cncmanufacturer #machinetools #india #cncindia #ISO2302

Информация по комментариям в разработке