Rapid Heating and Cooling

Here's what Google translates directly.

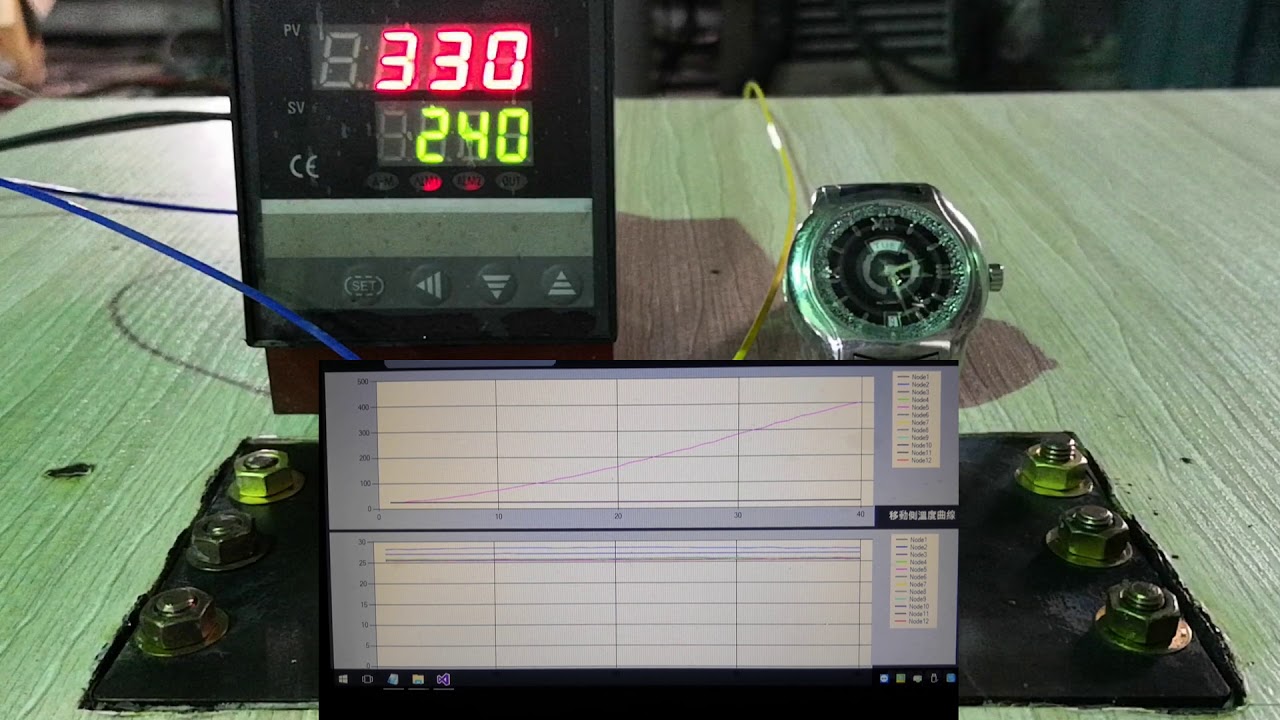

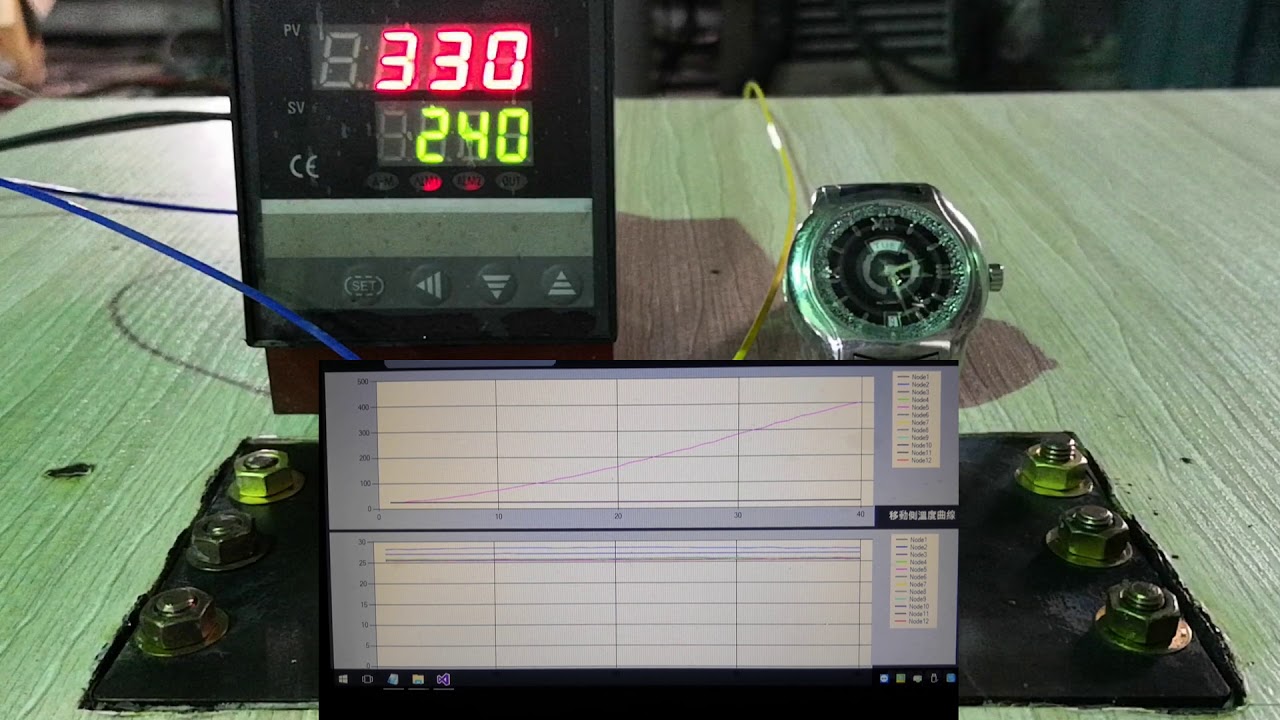

First explain the film 0~5 seconds is to seek cooperation company description, 6~15 seconds is the application of aluminum/magnesium alloy material, 16~20 seconds is the use power of the temperature rise and fall, and the number of seconds used to lift and lower the temperature, 20~21 seconds is the actual picture of the heating mold (the yellow and blue lines in the picture, the J&K Type thermocouple line, the temperature display and the heating control system next to the mold), 21~1 minute and 40 seconds is the mold The temperature rise and fall process (because there is nothing in the center of the mold, the temperature monitoring screen on the screen of the heating control system displays the temperature rise in the same way as the sub-picture, so that the viewer can more intuitively understand the power of the temperature rise and fall. When it starts to smoke at 300 degrees, the wooden board for shielding starts to smoke due to heat radiation, so it stops heating (otherwise the temperature can continue to soar). Now that the temperature of the mold (ren) rises to a few degrees, you can do that type of product to explain:

1. When the temperature is raised to 100 or 150 °C, the temperature is constant (depending on the product, and then the temperature is lowered to 60 °C).

The mold temperature is applied to the products of thermosetting composite materials. For example, the thermosetting carbon fiber door panel of a certain car manufacturer can take about 1 hour from the temperature rise to the temperature reduction. If we use our technology, we can reduce the hour to 1.5~3. Between the minutes (no matter the size of the mold can be reached), but unfortunately the car has invested heavily in the production line, no one dares to propose to the leadership to replace the process technology to reduce production costs and increase production capacity, thermoset composites can be applied There are so many, we will not list them one by one. Our focus in this temperature range is to reduce the cost of the process.

2. When the temperature rises to 180 to 400 °C, the temperature is lowered and then the temperature is quickly lowered to 60 °C.

This mold temperature is applied as a thermoplastic composite material. It can produce TPU/PC/PPS/PEEK as a lightweight product with different steel requirements for impregnated substrates. The cycle time depends on the product type. Between 30 seconds and 3 minutes.

3. When the temperature rises to 650 to 1100 °C, the temperature is lowered, and then the temperature is rapidly lowered to about 300 °C.

The mold temperature is applied to aluminum/magnesium alloy casting products (gravity/low pressure casting, die casting), foam aluminum products and aluminum/magnesium alloy composite products. For casting products, please see the video for 6~15 seconds.

Aluminum foam products:

Our technology can manufacture special-shaped foam aluminum products (including body parts with aluminum sheets on the surface) by mould technology. This is not a high-tech technology. It is only the temperature that the mold and material tubes cannot be heated up quickly until the aluminum alloy melts. In traditional injection molding, The application technology Mucell Injection is not unfamiliar to everyone. Our company only solves the bottleneck of mold temperature, and can easily produce body parts and other products with sandwich structure. At present, the foam aluminum process is limited, so the cost is high and the application is limited. However, our technology can make this product greatly reduce the cost and become popular. If this technology learns to be willing to come out and integrate the car factory, our company is willing to cooperate.

Aluminum/magnesium alloy composite products:

The academic research report pointed out that in order to make the aluminum alloy fully improve the wettability of the impregnation, the temperature of the aluminum alloy must reach above 1000 °C in order to obtain the best combination. This technical requirement is unattainable in the industry that requires mass production, but I The rapid heating technology of the mold can make it a technology that can be mass-produced, allowing lightweight to add a choice of materials.

4. When the temperature rises to above 1650 to 2500 °C, the temperature is lowered and then rapidly cooled to about 300 °C.

This part is a high-temperature metal/non-metal composite product application, and it is sensitive in aerospace and military applications. It is not explained here.

Reaffirming that our company's technology is not authorized for an unlimited amount of time, and that it is only possible to lose the opportunity to obtain technical authorization. This is a technical elimination tournament, and it depends on how the leadership of the company decides.

Информация по комментариям в разработке