Contact us via email [email protected] or whatsApp +8615811882441 for the machines shown in the video.

Engineer sales Jack Du

Wechat: +8615811882441

Website site source from www.penglaichina.com

www.gdpenglai.com

The Product Description

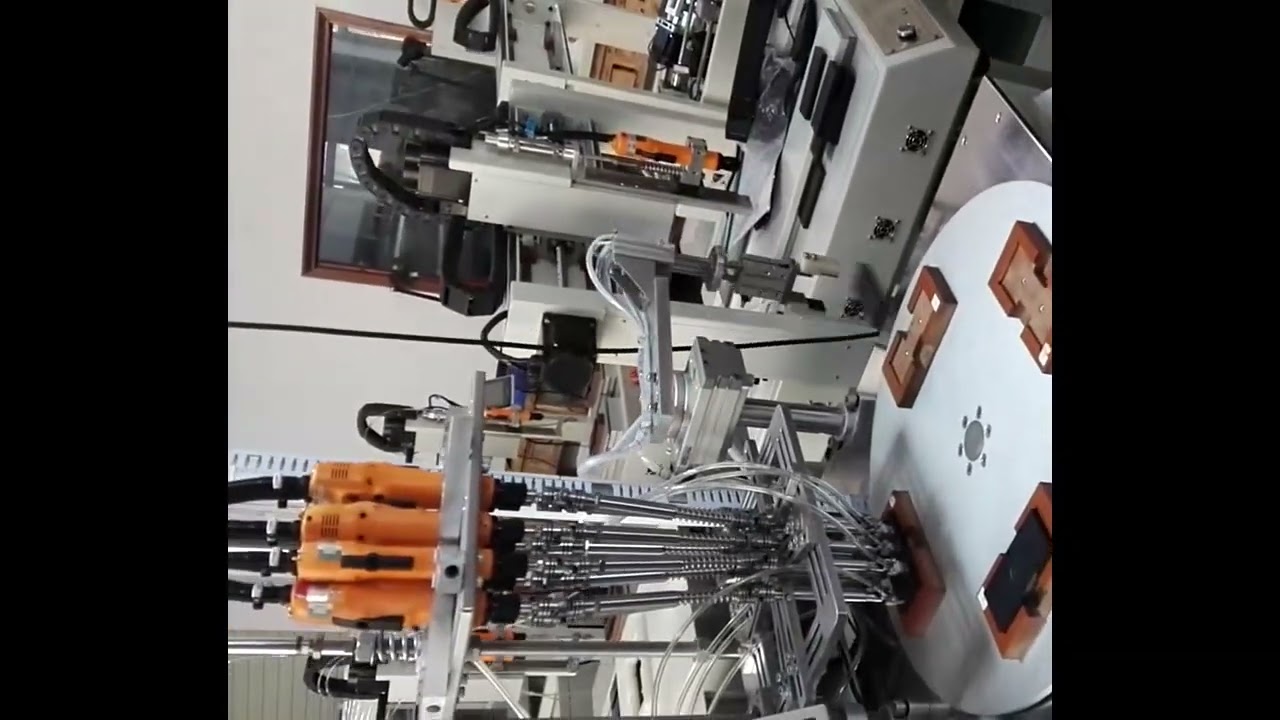

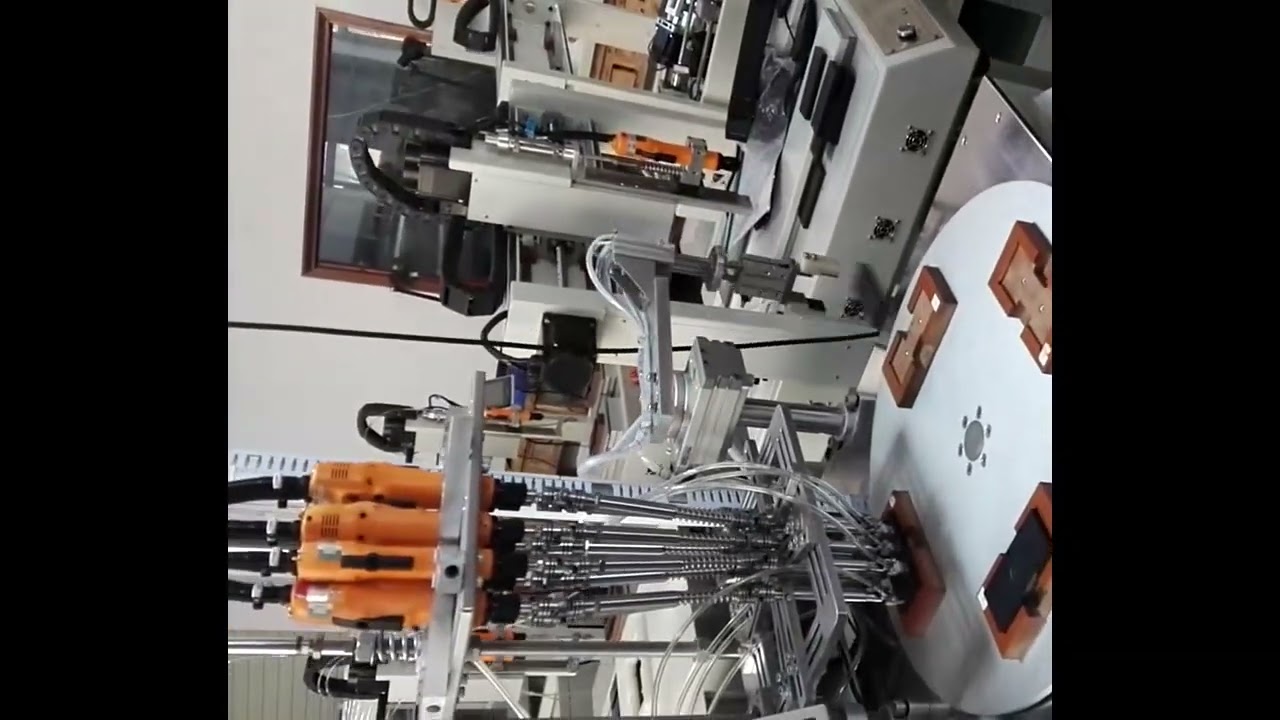

Automatic screw locking machine, as an intelligent equipment replaced the people operation, has been widely used in small household appliances, electronic products, instruments, LED, communication, mobile phones, tablets, Laptop, keyboard and other production and assembly industries of screw locking operation

It is mainly composed of screw automatic supplying system, axes movement platform, control system and locking/fasten system. The work efficiency is much higher than the traditional manual work.

Automatic robot screw tight machine is with various types: single platform, double platform, screw feeding system has two mode of single screw feeder and double screw feeder, the screw feeder has two mode of blowing and suction to meet different product requirements. The automatic robot screw locking machine programmed by teaching pedant for easy operation with detection function as leak lock, sliding teeth, floating lock and so on.

The machine features

1.Save labor. The machine is special for assembly line, equipped manipulator and turntable, to achieve feeding, detection, locking, take and place product synchronous operation, completed by the equipment automatically, save lot of labor;

2.Much higher efficiency improvement. Many electrical screw batch work at the same time, replace a number of workers, and the number of electrical screw batch can be customized according to customer requirements;

3.Intelligent. The machine with intelligent detection function, can detect missing lock, float lock, sliding teeth, etc;

4.Wide universality, it can adapt to M1.0-M5 screw locking if replacement screw transfer module;

5.Strong flexibility, equipped universal fixture for a variety of machine types of screw locking;

6.High efficiency, because it is completely eliminate hand, scrap screw, movement, screw on the screwdriver, no waiting time, just to be on the screw holes position to lock the screw, especially suitable for mass production;

7.Stable performance. Key parts of high-quality metal materials by special treatment, electronic components imported from the original, to ensure zero fault equipment.

Specification

Product Name

Automatic Locking Screw Machine With Rotary Multi-spindle

Model

CBLS-JDZ

Stroke range X/Y /Z(mm)

\

Efficiency size

\

Movement speed(mm/second)

0.1-800/400

Repeated precision

±0.02mm(Z), ±0.02°R

Program record mode

999 groups,100ints per group

Electric batch

Servo electric batch

Electric control mode

PLC

Display mode

Touch screen

Motor system

High power Motor

Control system

PLC

Transmission mode

Precision timing belt

Alarm function

Floating lock, sliding teeth, missing lock, torque check, etc.

Voltage

AC110/220V, 50/60HZ

Air Pressure 0.5MPA(5 cm2)

Screw feeding mod

Blowing

Control Panel

Touch screen

Working Temperature

0--40℃

Working humidity

20-90%

Applicable screw

M1.0-M5.0

Working Efficiency

0.8-1.5s/screw

Packing Dimension(L*W*H)

800*600*1800mm

Net weight(kg)

200kg

After-sales service on packaging and assemblying machinery of hardware/plasticware/metalware products like nuts bolts screws fasteners etc:

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse,misapplication, storage damage,

negligence, or modification to the Equipment or its components.

ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install

and test the machine and also training your worker to operating the machine (The time of train depend on you worker).

The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. also you can go to our factory to do training.

After-sale service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible.The cost should be in your account.(as above).

PENGLAI INDUSTRIAL CORPORATION LIMITED

US agent Office

9284 talway cir Boynton beach. fL 33472

Contact: Jack Du

Cel: 0086-15811882441 0086-13077872898

Tel:0086-755-86718316

Fax: 0086-755—25417648

Email: [email protected]

Skype: turnanewleaf

Website:

http://penglaimachines.com

/ penglaichina

/ mrjackdu007

/ cosmeticmachines

Информация по комментариям в разработке