Still curious about Belden Bonded Pair cable? Check out our white paper Bonded-Pair Cable to learn more about the importance of keeping your network safe and secure with our new patented technology.

https://www.belden.com/white-paper-bo...

Transcript:

This is communication cable. Look what

you can do with it. You can bend it, you

can coil it, you can twist it, you can

loop it, you can apply extreme force to it, you can put

electrical surge through it, set fire to

it, or stir coffee. And I'm sure it will

survive and still communicate

mission-critical signals, so who cares

what's inside.

The truth is, physical equals electrical. Any change in physical

structure of the cable will change its

electrical performance. Ethernet cable is

built to transmit data from point A to

point B. Those signals, your signals, could

be running manufacturing production

lines or operating water purification

plants or providing security footage on

commuter train platforms. At Belden we've

spent years testing, torturing, and

thoughtfully analyzing all types of cable.

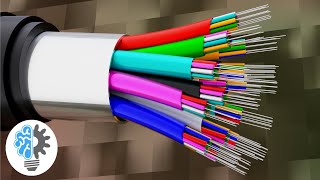

Let's take a look inside a cat6

Ethernet cable to see what really

happens there. Here,

strands of copper are jacketed in

conductor insulation and pairs are

twisted along the longitudinal axis.

The conductor, two conductor spacing is known

as centricity. For the most reliable

signal quality, you need uniform

centricity, or no gap between the

conductors. But what happens in the real

world? Just installing the cable results

in looping, pulling, bending, and twisting.

Put it on a robot and you get repetitive

flexing for hours on end. An ordinary

cable, all this activity starts to break

down the centricity, gaps form.

In test lab simulations we measured what

happens to the impedance, or electrical

resistance to the signal. You can see it

begins to break down pretty quickly.

That means your signal is getting

disrupted. When that happens, production

lines shut down, water stops flowing,

video images break up, and your money

goes down the drain.

At Belden we believed we could do

something about this performance issue

so we developed a unique, patented

technology called bonded pair that

ensures no gap between any twisted pair,

no matter the twisting, looping, bending,

or manipulations. After extensive testing

cycles here's what the impedance chart

looks like for cat6 bonded pair cable.

From installation onward, the stability of

bonded pair cable impedance means more

reliable performance for your operation.

Bonded pair also helps make the cable

more durable with a max pull tension of

45 pounds per foot compared to 25 pounds

per foot specified for 4 pair horizontal

cables. Bonded pair cable is not only 60

percent stronger, but also suitable for

high flex applications. 7938A, as an example, passed ten million

flex life cycle tests. Its physical

reliability and electrical performance

give you the peace of mind. Your

production lines keep running, your

utilities keep supplying customers, and

your security system keeps your site and

your passengers safe. We even guarantee

our cable for 10 years. You can trust

Belden for the innovation and quality

you need. Our groundbreaking bonded pair

technology is just one way we're making

industry better. See our entire portfolio

of cable solutions and be certain with Belden.

![Making of: rope reel with bearing [for cable cam]](https://i.ytimg.com/vi/pP2g4rHv0Uo/mqdefault.jpg)

Информация по комментариям в разработке