Key Characteristics of Crane Welding

1. Specialized Materials: The primary materials welded are crane steel structures, commonly using low-alloy high-strength steels like Q235B and Q345B. These steels offer good weldability but still demand strict adherence to welding procedures.

2. Complex Structures, Thick Plates: Main girders, end trucks, and legs are large box-type or I-beam structures with substantial plate thickness. They contain numerous fillet welds and groove welds, making the control of welding stress and distortion a significant challenge.

3. Dynamic Loading: Cranes endure dynamic loads such as impact and vibration during operation. Consequently, there are extremely high requirements for the fatigue strength of welds. Welds are not just connections but critical paths for force transmission.

4. Extremely High Safety Requirements: Weld failure can lead to catastrophic accidents. Therefore, welding quality must be flawless, adhering strictly to national standards and industry regulations.

2. Key Welding Processes & Techniques

Pre-Welding Preparation

Edge Preparation (Grooving): V-groove, X-groove, U-groove, etc., are prepared via machining or flame cutting based on plate thickness and welding method to ensure penetration.

Cleaning: Thoroughly remove oil, rust, moisture, etc., from the groove and adjacent areas (20-30mm) to prevent porosity and slag inclusions.

Preheating: Essential for thick plates or low ambient temperatures. Preheating slows the cooling rate of the weld joint, preventing the formation of cold cracks.

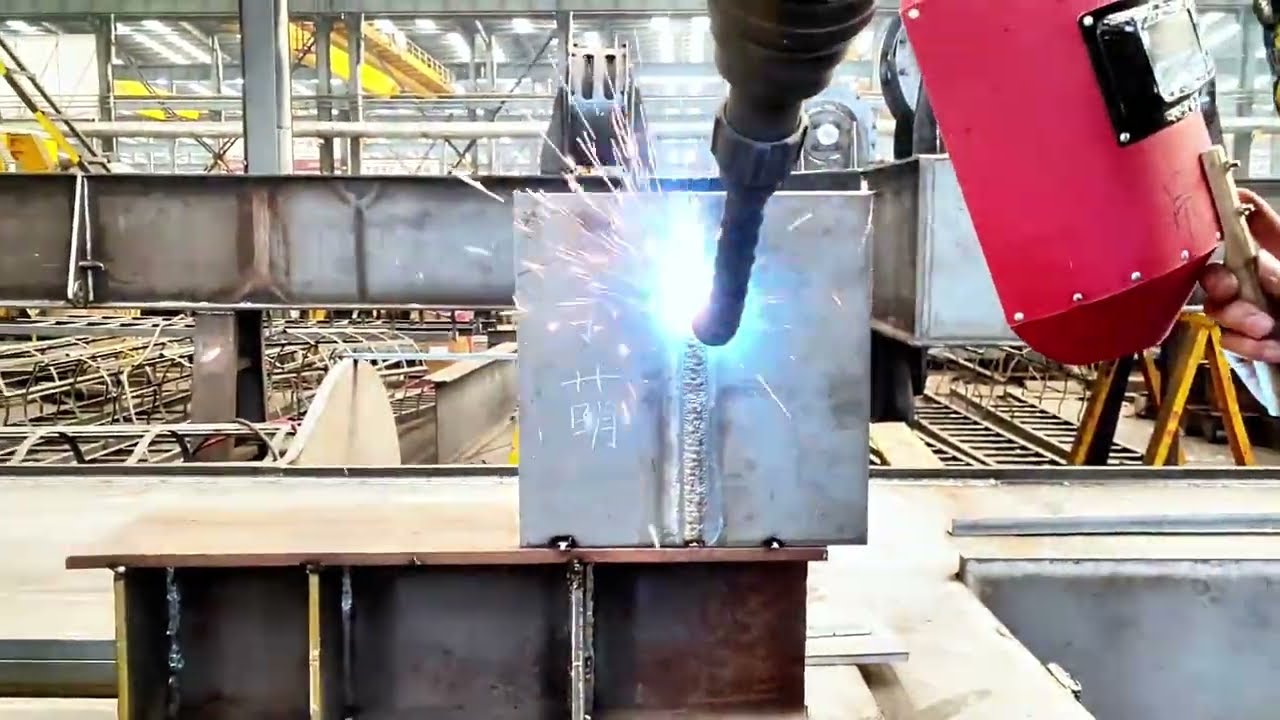

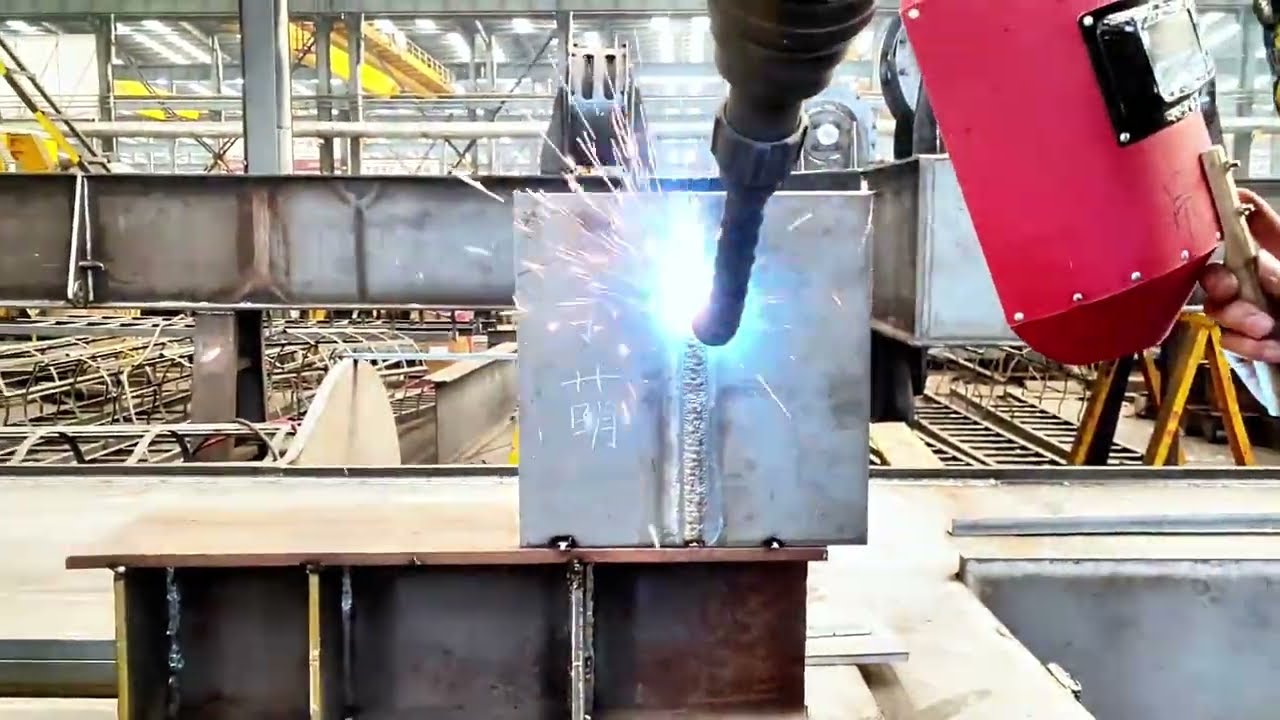

Welding Methods

Submerged Arc Welding (SAW): The primary welding method. Used for long straight seams and circumferential seams on main girders, end trucks, etc. Offers deep penetration, stable quality, high efficiency, good appearance, and no arc light/fumes.

Gas Metal Arc Welding (GMAW/MAG): Primarily rich argon mixture gas (e.g., 80% Ar + 20% CO₂) shielding. Used for non-linear welds, short welds, assembly tack welding, and repair welding in various positions. Highly versatile and widely used.

Shielded Metal Arc Welding (SMAW): Mainly used for on-site installation, repairs, irregular positions, and areas inaccessible to automatic welding.

Electroslag Welding (ESW): Sometimes used for vertical welding of very thick plates in older or specific designs, but often being replaced by more efficient methods like narrow-gap SAW.

In-Process Control

Distortion Control: A central challenge in crane welding.

Proper Welding Sequence: Use symmetrical welding, backstep sequencing, skip welding to distribute heat input.

Jigs and Fixtures: Use strong fixtures to rigidly hold the structure and suppress distortion.

Pre-Bending (Anti-Distortion): Pre-deform the workpiece in the opposite direction of expected welding distortion before welding to counteract it.

Multi-Pass Welding: For thick plates, multi-pass welding is mandatory. Each layer should not be too thick. Carefully clean interpass slag to prevent inclusions.

Post-Weld Treatment

Post-Heating & Insulation: For critical welds, apply post-heat treatment immediately after welding to allow hydrogen diffusion, further preventing delayed cracking.

Stress Relief Heat Treatment (SR): Performed on particularly critical structural components or thick plates to relieve residual stresses and improve joint properties.

Weld Toe Grinding: Grinding the weld reinforcement flush, especially in stress concentration areas, can improve the structure's fatigue strength.

3. Common Welding Defects & Prevention

Cracks (Hot, Cold): The most dangerous defect. Prevent by controlling material chemistry, preheating, using low-hydrogen consumables, controlling heat input, and post-weld insulation.

Lack of Penetration / Incomplete Fusion: Caused by improper groove geometry, low current, or high speed. Strictly follow the procedure.

Porosity: Caused by damp consumables, poor cleaning, or impure shielding gas. Dry electrodes/fluxes and ensure proper cleaning.

Slag Inclusions: Result from inadequate interpass cleaning or incorrect parameters.

4. Quality Control & Inspection

Crane welding implements full-process quality control.

Welder Qualification: Welders must hold a Special Equipment Operator Certificate (Welding) issued by the relevant regulatory body and work within their certified scope.

Welding Procedure Qualification (WPS/PQR): Before production welding, a procedure qualification test must be conducted according to standards to verify the procedure's correctness. A Welding Procedure Specification (WPS) is then created to guide production.

Non-Destructive Testing (NDT)

Visual Testing (VT): 100% inspection.

Ultrasonic Testing (UT): Performed 100% or by sampling rate on primary load-bearing welds to detect internal defects.

Radiographic Testing (RT): Used for specific critical welds. Higher cost but provides a permanent record.

Magnetic Particle Testing (MT) / Liquid Penetrant Testing (PT): Used for detecting surface or near-surface defects.

Информация по комментариям в разработке