Contact us for a free quote: www.aceretech.com

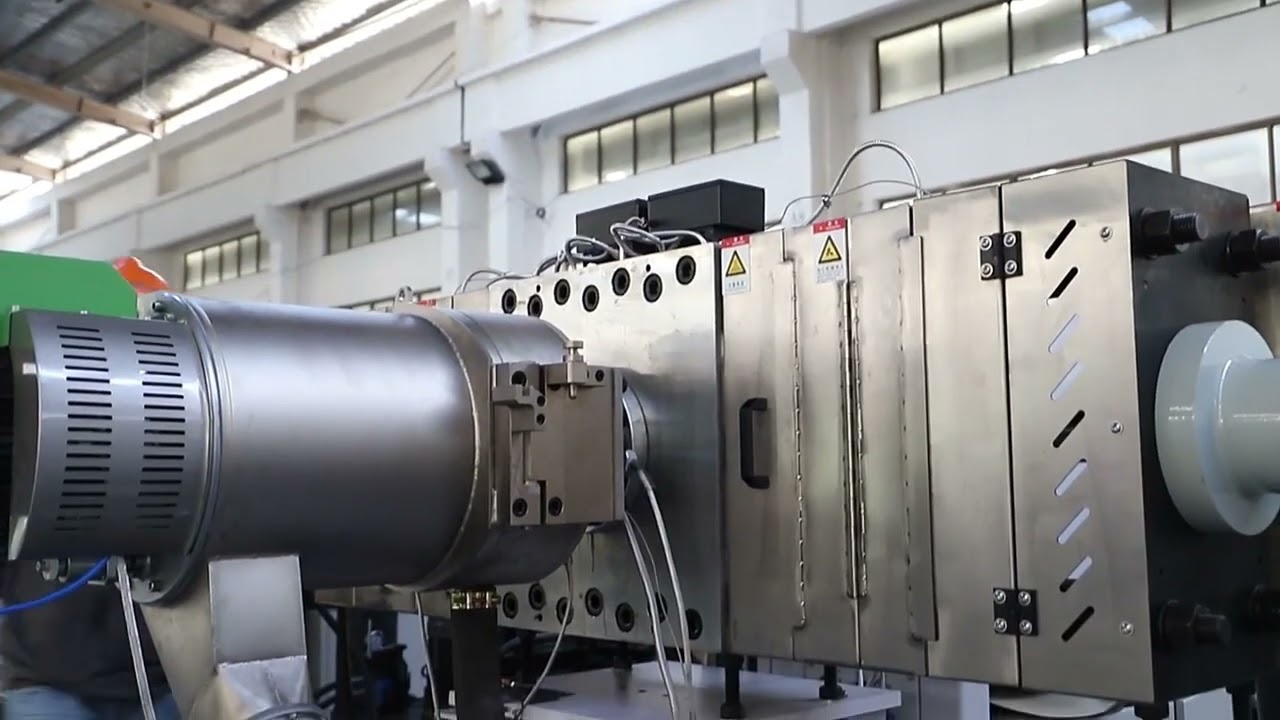

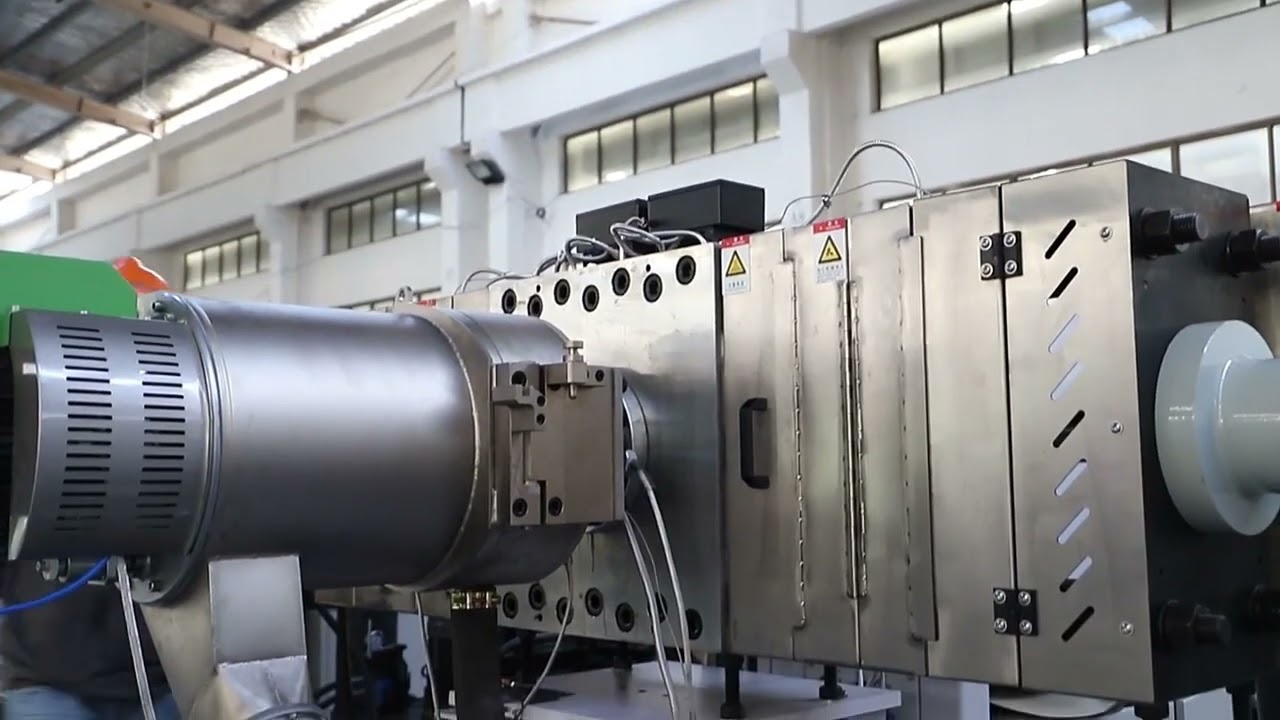

ASE Single-Screw Rigid Plastic Granulator: Efficient Recycling, Reclaiming Value - Your Rigid Plastic Recycling Solution

Faced with the growing amount of rigid plastic waste (such as HDPE, PP, ABS, PC, etc.), how can you efficiently convert it into high-value recycled pellets? The ASE single-screw extruder granulator, with its professional and reliable design, is your ideal recycling tool! Designed specifically for processing shredded or flake rigid plastics like PE/PP/ABS/PS/HIPS/PC, it integrates plasticizing, filtration, and granulation, ultimately producing high-quality pellets ready for film blowing, pipe extrusion, and injection molding, helping companies achieve resource recycling and cost optimization.

Core Advantages, Leading the Industry

✅ Superior Wear Resistance, Extended Lifespan: A bimetallic screw and wear-resistant barrel easily handle rigid plastic processing, significantly extending the equipment's service life.

✅ Efficient Plasticization, Guaranteed Quality: The 38:1 ultra-long aspect ratio design and dual vacuum degassing system thoroughly remove volatiles and moisture, ensuring uniform and pure pellets. ✅ Intelligent Operation, Hassle-Free and Convenient: The user-friendly touch interface supports multi-language customization, one-touch start/stop, and remote monitoring functions make production management more efficient.

✅ Flexible Adaptability for a Wide Range of Applications: Multiple models are available, ranging from 120 kg/h to 1000 kg/h, compatible with various processes such as water ring pelletizing, strand pelletizing, and underwater pelletizing, meeting different production capacity requirements.

✅ Compact Design, Space-Optimized: The modular structure occupies a small footprint, making it particularly suitable for recycling workshops with limited space.

Innovative Technology, Enhanced Efficiency

Advanced Filtration System: The standard dual-piston, non-stop screen changer and optional self-cleaning filter (SCF) can handle up to 5% of contaminants, ensuring continuous and stable production.

Intelligent Control and Automation: The ACS system implements interlocking control throughout the entire process, reducing manual intervention and improving production safety.

Energy-Saving and Environmentally Friendly: The ceramic/far-infrared heaters paired with a high-efficiency dehydration device provide low energy consumption and excellent drying results, in line with green production trends.

From waste to pellets, a one-stop solution.

The ASE production line covers the entire process from screw loading, main feeding, single-screw extrusion, double vacuum degassing, precision filtration, pelletizing, vibration drying, and packaging. The final pellets can be directly put into secondary production, creating sustainable economic value for your business.

Choose the ASE single-screw rigid plastic pelletizer now to transform waste plastics into valuable resources and start efficient waste plastic recycling!

#plasticgranulator #plasticrecyclingmachine #plasticrecyclingprocess #plasticpelletizingline #plasticpelletizer #aceretech

Информация по комментариям в разработке