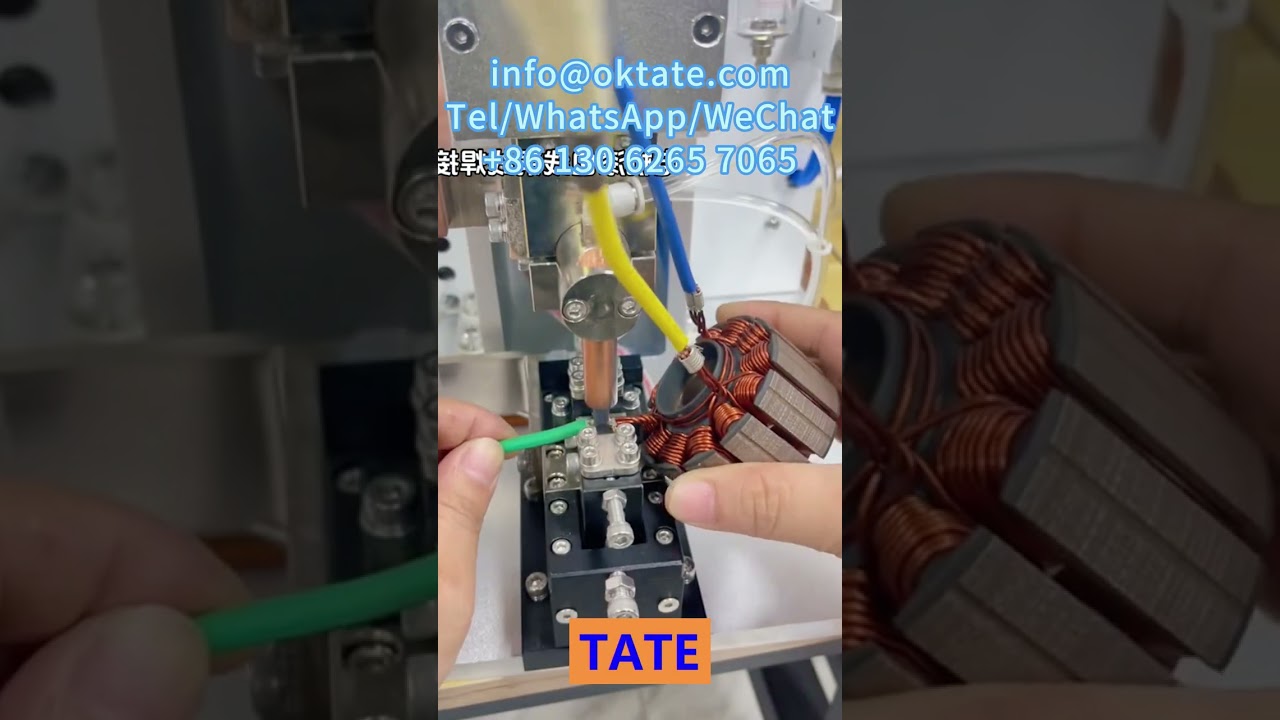

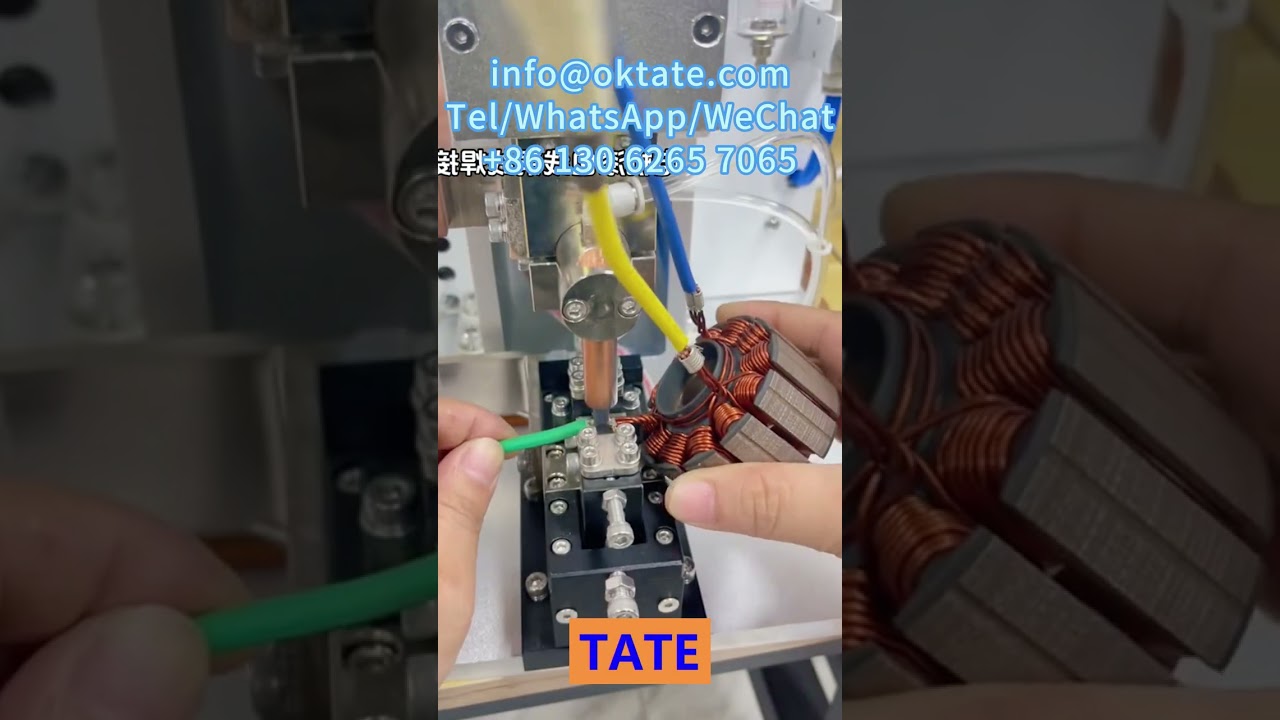

Motor Enameled Wire Spot Welder Source Factory WhatsApp: +8613062657065

How to Weld Motor Copper Enameled Wire? Just use the TATE MF Precision Spot Welder

Detail Visit: https://tateweld.com/category/product...

Make sure to subscribe, so you do not miss out my future videos

/ @cncspotwelder

================

Jack

Sales Manager

Tel: +86 130 6265 7065

WhatsApp: +8613062657065

WeChat: +8613062657065

Email: [email protected]

Website: https://oktate.com

================

Motor Enameled Wire Precision Spot Welding Machine | High-Speed Joining Without Paint Removal – TATE

The TATE Motor Enameled Wire Precision Spot Welding Machine is a state-of-the-art solution designed for high-speed joining of enameled copper wires used in electric motors, transformers, solenoids, coils, and electronic components. With advanced capacitor discharge (CD) spot welding technology, this machine welds directly through the enamel coating, eliminating the need for paint stripping while ensuring strong, low-resistance joints.

Conventional wire joining requires manual stripping, which is time-consuming, inconsistent, and may damage delicate copper wires. The TATE machine revolutionizes this process by delivering precision welds at lightning-fast speed, providing manufacturers with higher productivity, superior welding quality, and significant cost savings.

✅ Key Features and Advantages

No Paint Removal Required – Direct welding through enamel insulation saves labor, time, and materials.

High-Speed Welding – Precision control enables rapid joining of wires for mass production of motors and coils.

Superior Weld Strength – Creates strong, reliable, and low-resistance connections for stable electrical performance.

Precision Digital Control – Adjustable weld current, pressure, and timing ensure consistent results across all wires.

Minimal Heat Damage – Capacitor discharge technology delivers focused energy, preventing overheating and insulation damage.

Durable Electrodes – Equipped with tungsten-copper alloy electrodes for long service life and repeatable weld quality.

Compact & User-Friendly – Small footprint with a simple interface, ideal for integration into production lines.

Low Maintenance Cost – Fewer consumables and durable design ensure long-term efficiency.

⚙️ Technical Specifications

Brand: TATE

Welding Method: Capacitor Discharge (CD) Precision Spot Welding

Wire Diameter Range: 0.15 mm – 3 mm

Applications: Motor coils, transformers, relay wires, solenoids, brushless motor windings

Cycle Time: 0.1 – 0.3 seconds per weld

Electrode Life: 30,000 – 50,000 welds depending on material

Power Supply: 220V / 50Hz (customizable)

Cooling System: Air-cooled, with water-cooled option for continuous high-speed operation

🌍 Applications Across Industries

The TATE Precision Spot Welding Machine is ideal for a wide range of industries requiring fast, reliable, and consistent wire welding:

Electric Motors – Stator winding wires, rotor wires, brushless DC motors

Transformers – High-speed joining of enameled copper wire for compact transformers

Home Appliances – Fans, compressors, and washing machine motor wire welding

Automotive – EV motors, ignition coils, sensors, and alternators

Electronics – Relay coils, PCB wire connections, solenoids

Power Tools – Drill motors, grinders, and other handheld device coils

Aerospace & Defense – Lightweight and high-reliability winding applications

🌟 Why Choose TATE?

TATE is a global leader in innovative welding technology, providing solutions that are efficient, precise, and cost-effective. With years of engineering expertise, we design machines that help manufacturers reduce labor, improve quality, and scale up production. Our Motor Enameled Wire Spot Welding Machine ensures flawless performance, high durability, and the best price-to-performance ratio in the market.

By choosing TATE, you invest in:

Consistent Quality – Every weld is precise, repeatable, and durable.

Higher Productivity – Rapid welding process for mass production.

Reduced Costs – No need for stripping, soldering, or consumables.

Trusted Support – Professional after-sales service and technical guidance.

❓*FAQs*

Q1: Do I need to strip the enamel coating before welding?

A1: No. The TATE machine welds directly through the enamel insulation without stripping.

Q2: What wire sizes can the machine handle?

A2: It supports wire diameters from 0.15 mm up to 1.6 mm.

Q3: Is it suitable for stranded wires?

A3: Yes. It can weld both single-core and multi-stranded enameled wires effectively.

Q4: What industries use this machine?

A4: Motor manufacturing, transformers, automotive, appliances, electronics, and aerospace.

Q5: How fast is the welding process?

A5: The cycle time is typically 0.1 – 0.3 seconds per weld, ensuring high productivity.

Q6: Does it damage the insulation around the wire?

A6: No. Capacitor discharge technology minimizes heat spread, preserving nearby insulation.

Информация по комментариям в разработке