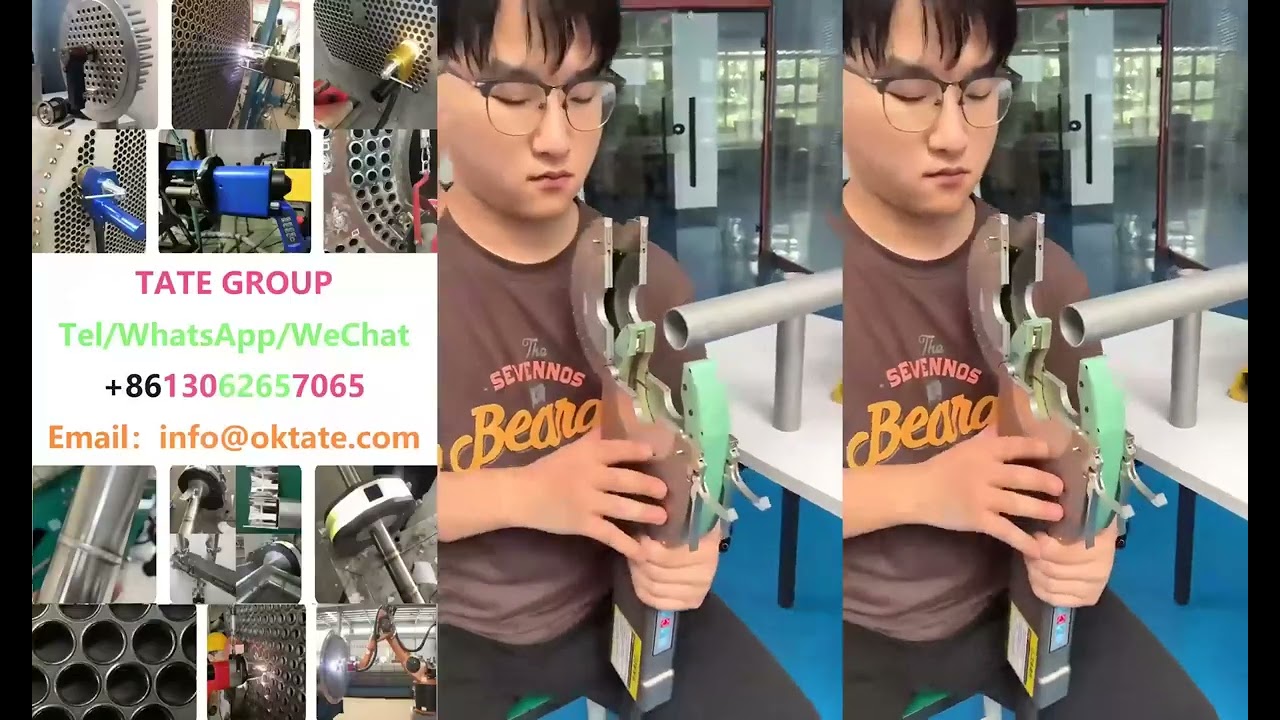

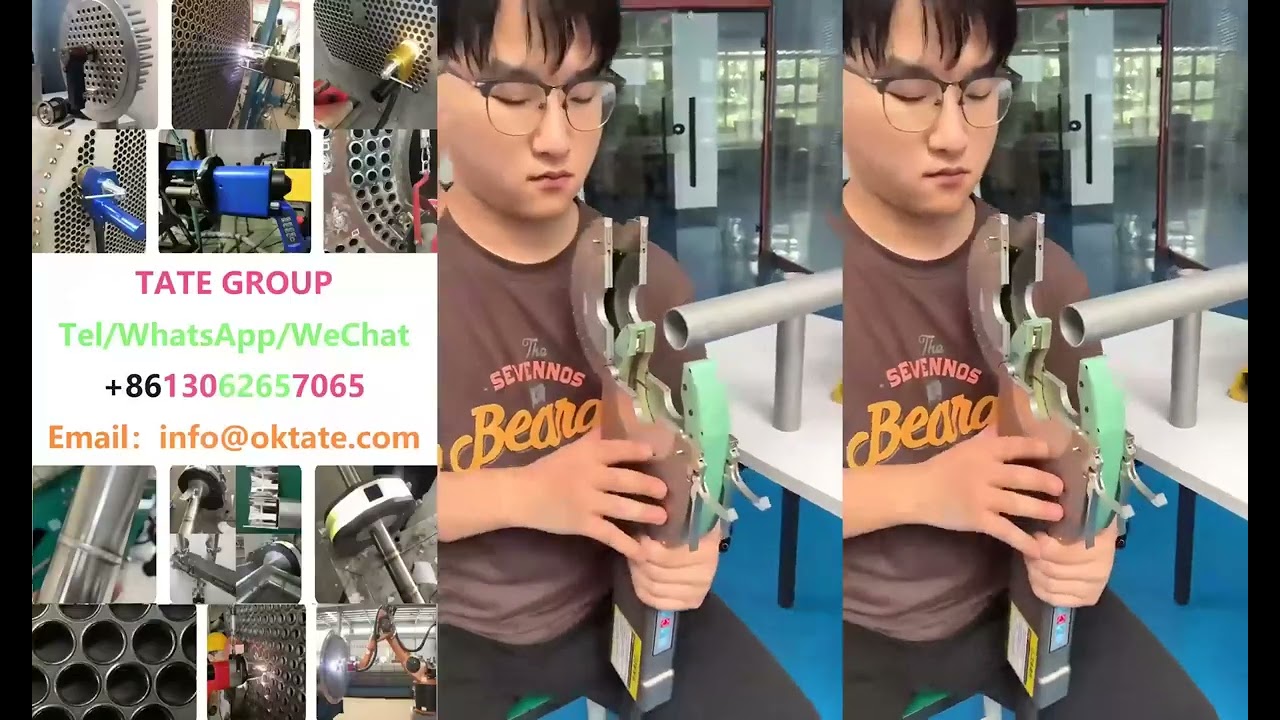

Orbital Tube Pipe Automatic TIG Welding Machine Source Factory WhatsApp: +8613062657065

How to quickly weld Tube Pipes? Just use TATE Automatic TIG Orbital Welder

Make sure to subscribe, so you do not miss out my future videos

/ @cncspotwelder

Reduce Costs With Factory Direct Sourcing.OEM/ODM Available!

=====================

Jack

Sales Manager

Tel: +86 130 6265 7065

WhatsApp: +8613062657065

WeChat: +8613062657065

Email: [email protected]

Detail Visit:www.tateweld.com

=====================

Welcome to our comprehensive guide to orbital welding machines, where we delve into the features, advantages, and applications of these cutting-edge welding systems. Whether you're new to orbital welding or you're seeking advanced insights into automated welding processes, this video is designed to provide everything you need to know about these high-precision tools. If you're in the market for a welding machine that ensures accuracy, repeatability, and high-quality welds.

What is an Orbital Welding Machine?

An orbital welding machine is an automated welding system that offers unparalleled precision and repeatability. Unlike traditional manual welding, orbital welding involves the rotation of the welding head around a fixed pipe or tube, ensuring a continuous, uniform weld. This unique process minimizes the likelihood of human error and enhances the overall quality of welds. By utilizing robotic welding technology, these machines can perform high-quality welds on materials such as stainless steel, titanium, aluminum, and even exotic alloys.

In industries where precision is paramount, orbital welding machines are the go-to solution for producing defect-free, durable welds. These systems are capable of delivering consistently smooth and uniform welds with minimal spatter or distortion, making them ideal for critical applications in industries such as pharmaceuticals, semiconductors, aerospace, and nuclear energy.

Key Features of Orbital Welding Machines

Precision Welding: Orbital welding systems provide superior control over welding parameters such as heat input, voltage, and current, allowing for consistent and defect-free welds. Whether you’re welding thin-walled tubes or large-diameter pipes, orbital welding machines maintain the highest levels of precision.

Automated Process: The automated nature of orbital welding drastically reduces the need for manual labor. With the ability to program and monitor welding parameters, operators can set up the machine for a wide range of applications, reducing errors and enhancing welding efficiency.

Consistency and Repeatability: Once the welding parameters are set, orbital welding machines can repeat the same welding process for hundreds or even thousands of parts. This consistency ensures high-quality results, even when working with complex geometries or materials.

Quality Assurance and Data Logging: Modern orbital welding machines come equipped with advanced data tracking systems that log welding parameters and provide real-time feedback. This feature is particularly useful for industries that require strict compliance with regulatory standards, such as the pharmaceutical or food and beverage industries.

Wide Range of Applications: Orbital welding is suitable for a variety of industries, including aerospace, semiconductor manufacturing, nuclear power, and petrochemicals. These machines are versatile and can be used to weld a wide array of materials, from stainless steel and titanium to more complex alloys used in aerospace and semiconductor applications.

Reduced Downtime: The reliability of orbital welding machines leads to reduced downtime in production. These machines are designed for minimal maintenance, with features that automatically alert operators to potential issues before they cause system failures.

Enhanced Safety: Orbital welding machines also contribute to a safer working environment. The reduced need for manual intervention and the automated nature of the process help to mitigate risks associated with exposure to welding fumes, heat, and electric arcs.

Industries That Benefit from Orbital Welding Machines

Pharmaceutical Industry: Orbital welding is widely used in the pharmaceutical industry for its ability to produce clean, hygienic, and precise welds. Sanitary welds are essential for ensuring the integrity of fluid systems used in drug manufacturing and distribution.

Benefits of Using Orbital Welding Machines

Precision: Orbital welders provide consistent, high-quality welds that meet the highest industry standards.

Orbital welding, orbital welding machines, welding automation, stainless steel welding, titanium welding, aerospace welding, nuclear welding, automated pipe welding, precision welding, welding technology, industrial welding, pharmaceutical welding, food and beverage welding, semiconductor welding, welding quality assurance, repeatable welds, high-quality welds, welding machines, welding efficiency, welding automation

Информация по комментариям в разработке