Read the full breakdown here:

https://www.prv-engineering.co.uk/hidden-e...

Why Engineering Bottlenecks Rarely Appear at the Start

Early stages of manufacturing work often move quickly. Drawings are released, materials are ordered, machining begins and visible progress creates confidence.

Most engineering bottlenecks surface later when components move from manufacture into finishing, assembly, compliance, and installation. At this stage, flexibility narrows and the cost of change rises sharply.

Industry data reinforces this pattern. According to Make UK, many manufacturers continue to operate under capacity and supply-chain pressure, meaning late-stage disruption is far harder to absorb once production is underway.

In practice, engineering bottlenecks most commonly arise where tolerance, finishing, and integration requirements converge.

Finishing as a Potential Engineering Stumbling Block

Finishing processes rarely receive the same attention as machining or fabrication, yet they are among the most schedule-sensitive engineering bottlenecks in any project.

Processes such as powder coating, wet spray painting, and surface preparation depend on:

clean handovers

correct sequencing

controlled environments

realistic curing and inspection times

When finishing is treated as interchangeable or easy to compress, projects lose time correcting defects, reworking parts, or waiting for availability. Finishing introduces time constraints that cannot be accelerated without affecting quality or compliance. Read more on industrial finishing processes.

Coatings and Electroplating as Hidden Engineering Bottlenecks

Coatings and electroplating are often viewed as final steps, but in practice they create engineering bottlenecks that reach back into earlier stages of production.

Surface preparation, masking, material compatibility, and thickness control all determine whether components pass inspection first time. Late specification changes at this stage frequently require full reprocessing.

This is particularly critical in regulated or high-performance environments where coatings affect corrosion resistance, conductivity, or wear behaviour. Visit our website for more information on electroplating services at PRV Engineering.

Tolerance Stack-Up: One of the Most Common Engineering Bottlenecks

Individual components can meet specification perfectly and still fail as an assembly.

Tolerance stack-up, the cumulative effect of small dimensional variations, is one of the most underestimated engineering bottlenecks. It rarely appears during single-part inspection but becomes obvious during fit-up, assembly, or installation.

Once tolerance stack-up is discovered late, resolution options are limited and often expensive, involving rework, redesign, or compromise.

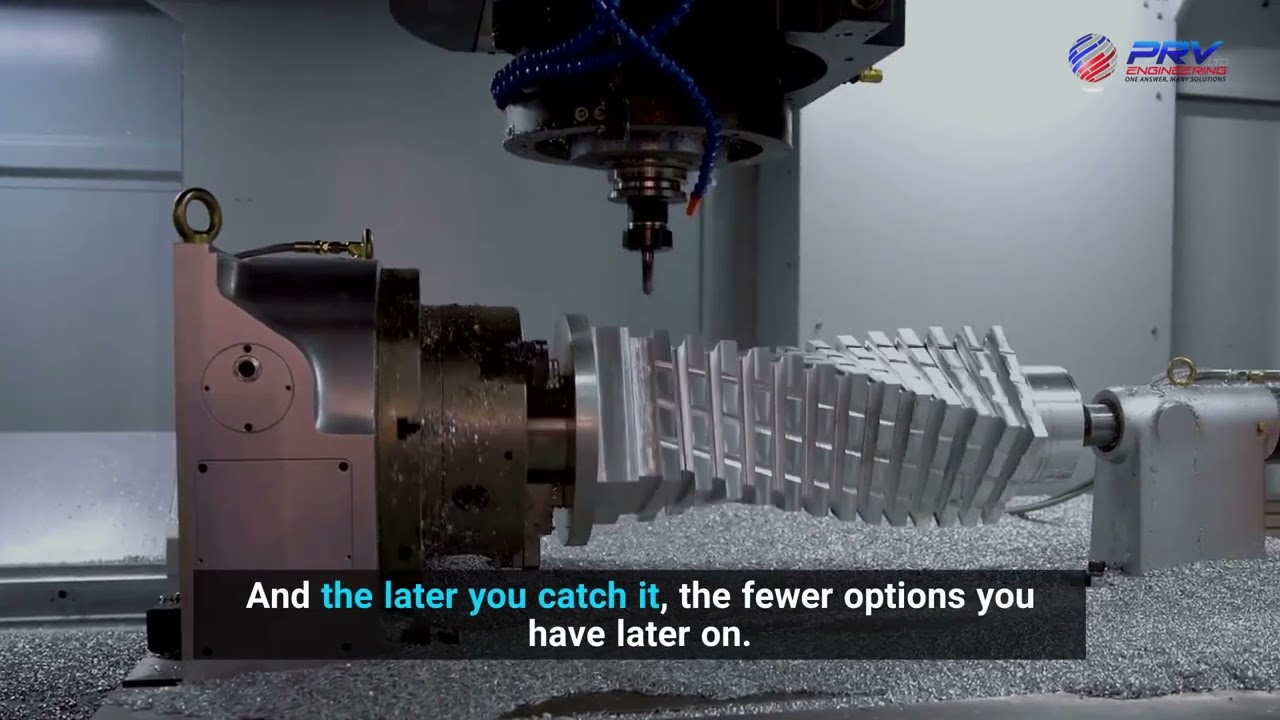

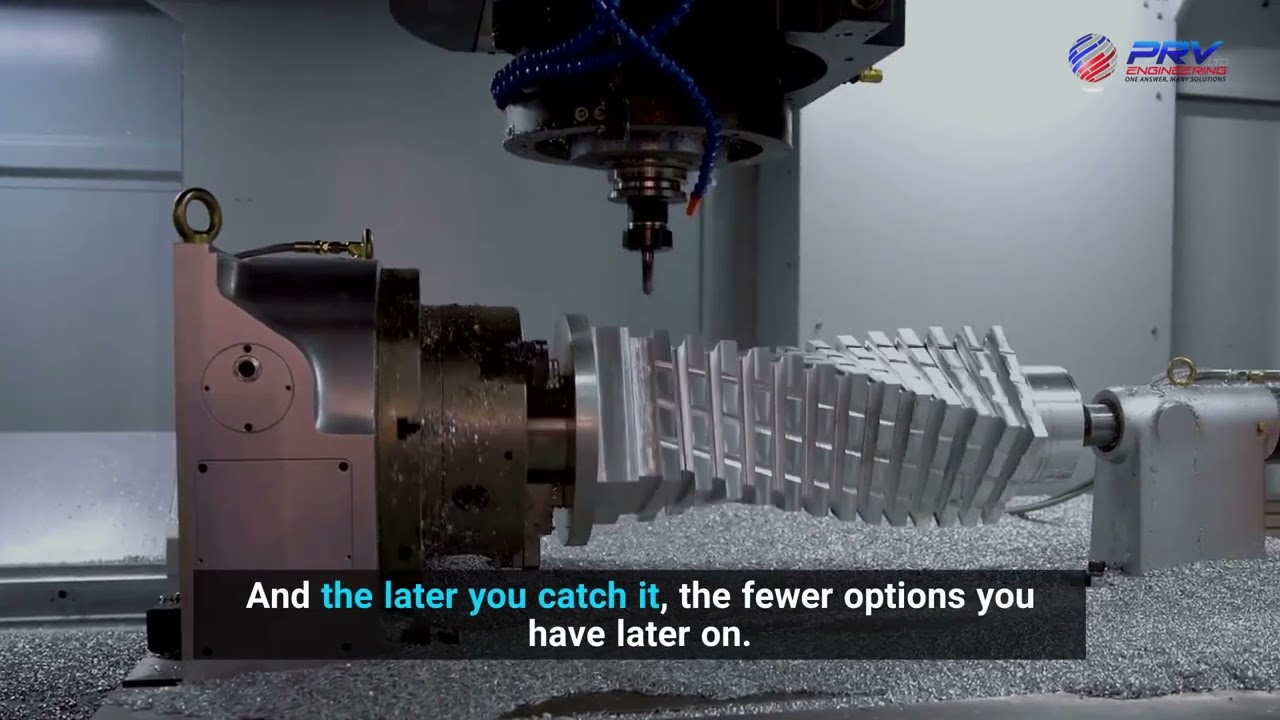

Illustration showing how tolerance stack-up and late-stage changes create engineering delays during assembly.

Late-Stage Changes Create Severe Engineering Bottlenecks

Change is inevitable in engineering work. What matters is when it occurs. Late-stage changes after machining, finishing, or coating create disproportionate engineering bottlenecks because:

rework affects multiple processes

documentation must be updated

inspections and approvals may need repeating

Changes that would be manageable early can stall delivery entirely when introduced late.

Documentation is Often Overlooked

Documentation rarely attracts attention until it becomes a problem. Certification packs, inspection records, material traceability, and compliance documentation are essential in many sectors, including defence, aerospace, rail, energy, and infrastructure.

When documentation is fragmented across suppliers or compiled after the fact, sign-off delays become unavoidable. Incomplete or poorly coordinated documentation remains one of the most persistent engineering bottlenecks during handover.

PRV Engineering supports complex programmes across sectors including defence, aerospace, rail, construction, energy, and automotive by combining machining, fabrication, waterjet cutting, finishing, and coatings within a coordinated, in-house environment.

This integrated approach allows potential bottlenecks to be considered earlier, reducing rework, improving predictability, and helping engineering projects progress with fewer surprises as complexity increases.

Other Useful links/Resources:

5-Axis Machining

https://www.prv-engineering.co.uk/Products...

Deep Hole Drilling

https://www.prv-engineering.co.uk/Products...

CNC Machining

https://www.prv-engineering.co.uk/Products...

Railway Engineering

https://www.prv-engineering.co.uk/Railway-...

Busbar Manufacturing

https://www.prv-engineering.co.uk/products...

Electroplating

https://www.prv-engineering.co.uk/products...

Информация по комментариям в разработке