Graphite Dust: Composition, Hazards, Properties, Air Scrubbing Filters

https://torch-air.com/blog/graphite-dust

Equipment selection and calculation department: [email protected]

Sales and Production Facility in Oklahoma: +1 (918) 406-5684

Sales Office in California:+1 (213) 403-6530

Host and Author: Michael Klepik.

Michael Klepik is an expert in the field of air purification. Mr. Klepik specializes in dust collectors, baghouses, scrubbers, and other equipment and technologies for industrial air pollution control.

Graphite is one of the most widely used carbon materials in industry — found in batteries, refractories, lubricants, carbon brushes, electrodes, and even in advanced materials like graphene. However, graphite dust — a byproduct of machining, grinding, cutting, and polishing operations — presents serious health, safety, and equipment challenges if not properly controlled.

This article explores the composition, hazards, properties, and filtration technologies used to handle graphite dust in industrial environments.

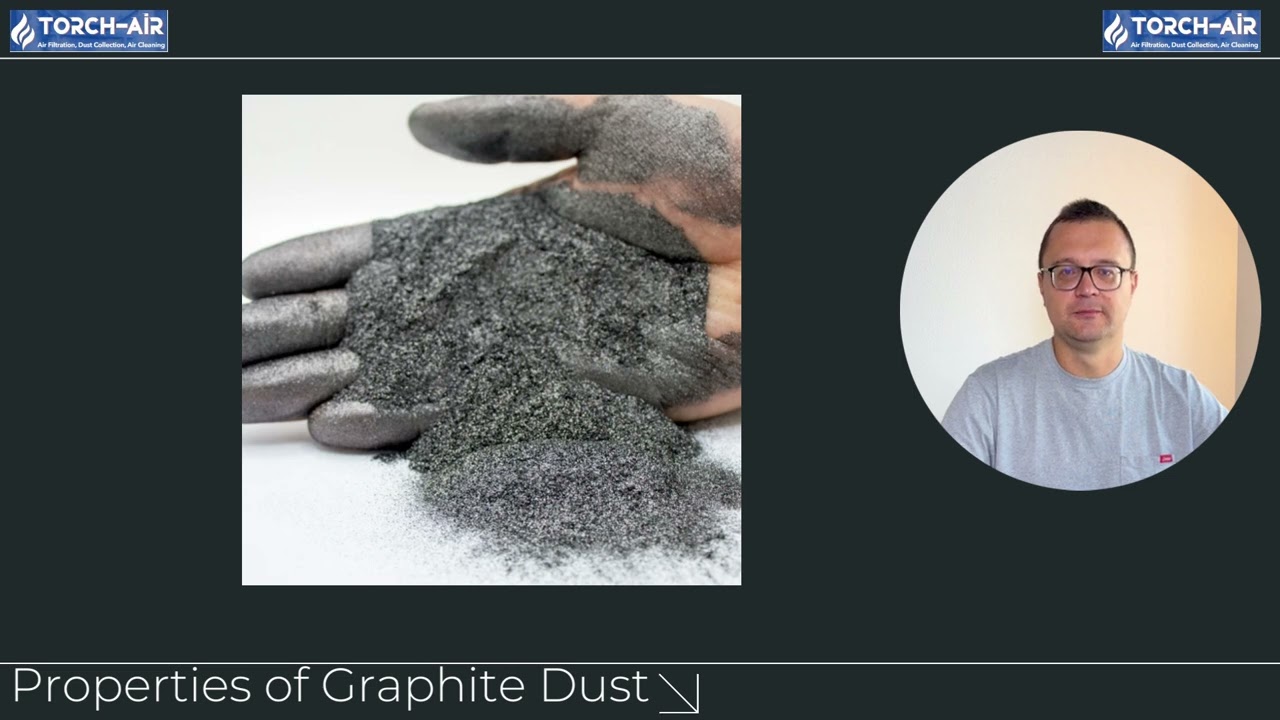

1. Composition and Sources of Graphite Dust

Graphite dust consists primarily of carbon particles (C) that are generated during mechanical or thermal processing of graphite-based materials. The particle size and structure depend on the process:

Machining and milling: Produces fine graphite particles under 10 µm.

Cutting and shaping: Generates larger flakes (10–100 µm).

Electrode manufacturing: Combines carbon dust with binders like pitch, tar, or resin.

Battery production: Generates ultrafine graphite dust mixed with metal oxides (e.g., LiCoO₂, NiMnO₂).

In many facilities, graphite dust is airborne due to its low density and flaky morphology, spreading easily through ventilation systems if not properly captured.

2. Physical and Chemical Properties

Chemical Formula: C (pure carbon)

State: Solid, fine particulate

Color: Black to gray

Density: ~2.2 g/cm³

Particle Size Range: 0.1–100 µm (depending on process)

Conductivity: Excellent electrical conductor

Flammability: Combustible when suspended in air as a fine dust cloud

Ignition Temperature: Approximately 700–800°F (370–430°C)

Health Hazards: Mainly from inhalation of respirable carbon dust

Reactivity: Stable; may oxidize slowly at high temperatures

3. Health and Safety Hazards

Although graphite is chemically stable and non-toxic in its solid form, graphite dust is a respirable particulate that can cause both acute and chronic health issues when inhaled.

3.1. Inhalation and Respiratory Effects

Long-term exposure can lead to graphitosis, a form of pneumoconiosis (lung disease) caused by prolonged inhalation of graphite or carbon dust. Symptoms include:

Chronic cough

Shortness of breath

Lung fibrosis

3.2. Explosion and Fire Hazards

Graphite dust can form combustible dust clouds in confined spaces. If mixed with air and exposed to an ignition source, it may result in deflagration or explosion — similar to aluminum or coal dust.

OSHA Combustible Dust Standard (CFR 1910.307) and NFPA 652 require risk assessment and proper dust collection for graphite-handling facilities.

3.3. Equipment Damage

Graphite’s abrasive and conductive nature makes it harmful to:

Bearings and fans, which can wear down quickly.

Electrical components, where dust may cause short circuits.

Sensors and actuators, where fine carbon particles interfere with signals.

4. Air Filtration and Dust Collection Systems

Because graphite dust is dry, fine, and conductive, it requires specialized air filtration and scrubbing systems designed to safely handle conductive carbon dusts.

4.1. Dry Dust Collectors (Preferred for Graphite)

Pulse Jet BagHouse Blizzard

A high-efficiency bag filter with automatic compressed air cleaning. Ideal for large volumes of fine, dry graphite dust.

Air-to-cloth ratio: 3–5 ft/min

Filter media: Antistatic felt (carbon-impregnated polyester or PTFE-coated)

Efficiency: Up to 99.9% at 1 µm

Cartridge Filters (FOEHN, AKMAN, PASSAT)

Used for smaller systems or point-source collection (e.g., CNC machines, grinding booths).

Advantages: Compact, easy maintenance, lower pressure drop

Filter media: Conductive nanofiber or cellulose-polyester blend

Cleaning method: Reverse pulse air cleaning

Bora Compact Filter

A small unit with an integrated fan used directly over machining stations. Perfect for portable or enclosed graphite-processing cells.

4.2. Wet Scrubbers (Secondary or Safety Stage)

While graphite is hydrophobic, wet scrubbers can be used as secondary filtration to remove remaining fine particulates or vapors.

TORNADO-RP Scrubber: Efficient for mixed particulate and vapor streams.

Venturi Scrubber: Uses high-velocity water jets to trap ultra-fine carbon dust; ideal when dust may have explosive potential.

Информация по комментариям в разработке