What is Friction Stir Welding?

The process was invented and experimentally proven at The Welding Institute (TWI) in Cambridge, UK in December 1991. And it’s defined as a solid-state process that uses a non-consumable tool to bond two facing workpieces without actually melting the working material.

The two workpieces can be joined using either a lap or butt weld orientation.

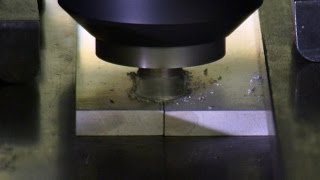

The process starts when heat is generated by friction between a rotating tool and the working material, which leads to a softened region near the rotating tool itself.

While all this happens, the tool is traversed along a joint line and mechanically intermixes the two pieces of metal, and forges the hot and softened metal through mechanical pressure, which is applied by the rotating tool.

Let’s talk a little about the rotating tool and some of its interesting attributes.

In order for the non-consumable rotating tool to produce a high-quality butt or lap weld. They are manufactured from a wear-resistant material with good static and dynamic properties that can withstand elevated temperatures. Current state-of-the-art tools can produce up to 1000m of weld at a rate of 5mm thick aluminum extrusions without changing the tool’s properties. Coupled with these temperature tolerances and its composition, the design of the friction stir welding tools themselves, is the heart of this remarkable and still relatively new welding process.

Generally, the rotating tool has a profiled pin and a shoulder with a larger diameter than that of the pin. For example, with butt joining, the length of the pin approximates to the thickness of the workpiece itself. When in use, the pin would traverse along the joint line while the shoulder is in intimate contact with the top surface of the workpiece, to avoid expelling softened material and provide adequate chemical consolidation.

One of the most critical settings to achieve successful friction stir welds is the position of the tool shoulder relative to the workpiece surface. To further optimize the role the shoulder plays, some manufacturers incorporate a mechanical position control system. This is accomplished by using single or dual rollers beside or in front of the rotating tool. These rollers guarantee that the tool does not plunge too deep into the workpiece and that the plasticized material is sufficiently forged underneath the tool shoulder.

Now, a good quality weld in aluminum alloys usually results in a well-developed nugget that should be visible at the center of a weld. This becomes evident when looking at a macro section of a given weld. The outside of the nugget has a thermomechanically affected zone, which has been plastically deformed and shows some areas of partial grain refinement. The overall shape of the nugget can vary, depending on the alloy used and the actual process conditions.

At this point, we’ve established that Friction stir welding is capable of joining aluminum alloy. However, it also has applications in joining copper alloys, titanium alloys, mild steel, stainless steel, and magnesium alloys. And even more recently, it was successfully used in the welding of polymers and in addition to, joining of dissimilar metals, such as aluminum to magnesium alloys.

Moreover, the load-carrying capabilities of joints bonded by using Friction Stir Welding are far superior than other bonding techniques. In studies, Friction Stir welding joints exhibited 75 per cent higher load-carrying capabilities when compared to riveted joints and TIG-welded joints.

It’s no wonder why the technique was first implemented in the manufacturing process of the external tank of the Space Shuttle Program in 2001. And the tank itself flew in 2009 and since then, NASA has developed multiple tools and advanced processes to enhance its welding capabilities on aerospace hardware.

Friction stir welding yields higher strength bonds with higher reliability and predictability. It also increases efficiency by reducing the number of weld passes that traditional fusion arc welding requires. In addition, it offers safer, more environmentally friendly operations than traditional welding by not creating hazards such as welding fumes, radiation or high voltage.

For these reasons, it will continue to be a critical technology as we continue to learn how to build more efficient space vehicles with less expensive materials.

Информация по комментариям в разработке