A steam turbine is a machine that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft, possibly using a renewable energy heat source. Its modern manifestation was invented by Charles Parsons in 1884.[1][2] Fabrication of a modern steam turbine involves advanced metalwork to form high-grade steel alloys into precision parts using technologies that first became available in the 20th century; continued advances in durability and efficiency of steam turbines remains central to the energy economics of the 21st century.

The steam turbine is a form of heat engine that derives much of its improvement in thermodynamic efficiency from the use of multiple stages in the expansion of the steam, which results in a closer approach to the ideal reversible expansion process. Because the turbine generates rotary motion, it is particularly suited to be used to drive an electrical generator—about 85% of all electricity generation in the United States in the year 2014 was by use of steam turbines.[3] A steam turbine connected to an electric generator is called a turbo generator.

As of 2021, among the largest steam turbines in the world is the Arabelle steam turbines manufactured by GE based on an original design by Alstom.[4] An Arabella turbine is 7 m in diameter, weighs 4000 tons and spins at 1500 rpm. In a typical nuclear installation, another 4000 tons of supporting steel structure is required, as well as 1000 tons of pumps, valves, and pipes.[4]

Technical concerns include rotor imbalance, vibration, bearing wear, and uneven expansion (various forms of thermal shock). In large installations, even the sturdiest turbine is capable of shaking itself apart when operated out of trim.

Principle of operation and design

An ideal steam turbine is considered to be an isentropic process, or constant entropy process, in which the entropy of the steam entering the turbine is equal to the entropy of the steam leaving the turbine. No steam turbine is truly isentropic, however, with typical isentropic efficiencies ranging from 20 to 90% based on the application of the turbine. The interior of a turbine comprises several sets of blades or buckets. One set of stationary blades is connected to the casing and one set of rotating blades is connected to the shaft. The sets intermesh with certain minimum clearances, with the size and configuration of sets varying to efficiently exploit the expansion of steam at each stage.

Practical thermal efficiency of a steam turbine varies with turbine size, load condition, gap losses and friction losses. They reach top values up to about 50% in a 1,200 MW (1,600,000 Principle of operation and design

An ideal steam turbine is considered to be an isentropic process, or constant entropy process, in which the entropy of the steam entering the turbine is equal to the entropy of the steam leaving the turbine. No steam turbine is truly isentropic, however, with typical isentropic efficiencies ranging from 20 to 90% based on the application of the turbine. The interior of a turbine comprises several sets of blades or buckets. One set of stationary blades is connected to the casing and one set of rotating blades is connected to the shaft. The sets intermesh with certain minimum clearances, with the size and configuration of sets varying to efficiently exploit the expansion of steam at each stage.

Practical thermal efficiency of a steam turbine varies with turbine size, load condition, gap losses and friction losses. They reach top values up to about 50% in a 1,200 MW (1,600,000 hp) turbine; smaller ones have a lower efficiency.[citation needed] To maximize turbine efficiency the steam is expanded, doing work, in a number of stages. These stages are characterized by how the energy is extracted from them and are known as either impulse or reaction turbines. Most steam turbines use a mixture of the reaction and impulse designs: each stage behaves as either one or the other, but the overall turbine uses both. Typically, lower pressure sections are reaction type and higher pressure stages are impulse type ) turbine; smaller ones have a lower efficiency.[citation needed] To maximize turbine efficiency the steam is expanded, doing work, in a number of stages. These stages are characterized by how the energy is extracted from them and are known as either impulse or reaction turbines. Most steam turbines use a mixture of the reaction and impulse designs: each stage behaves as either one or the other, but the overall turbine uses both. Typically, lower pressure sections are reaction type and higher pressure stages are impulse type .

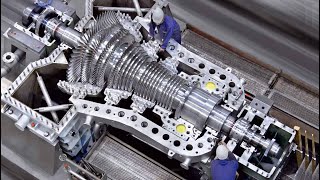

Siemens energy .

![Как работают Силовые Трансформаторы? [The science works на русском]](https://i.ytimg.com/vi/DcjGEJHwpDM/mqdefault.jpg)

Информация по комментариям в разработке