Please watch: "Learn Fabrication Layout development of all shapes in by reading Master in Fabrication layout eBook"

• Learn Fabrication Layout development ... -~-

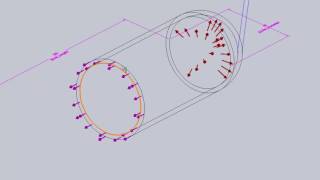

What Is Pressure Vessels: Pressure Vessel is Container designed to hold gaseous or liquids at pressure substantially different from the ambient pressure.

Classification or Types Pressure Vessels:

According to Fabrication: Shop Fabricated Pressure Vessels, Field Fabricated Pressure vessels, Riveted Pressure Vessels, Welded Pressure vessels, Forged Pressure Vessels, Cast Pressure Vessels, Multi layered Pressure Vessel.

According to Functions: Reactor, Accumulator, Columns, Drums, According to Material of Constructions, Steel Pressure Vessels, Cast iron pressure Vessels, Aluminium Pressure Vessels

According to Pressure: Internal Pressure, External Pressure, According to Method of Heating, Fired Pressure Vessels, Unfired Pressure Vessels, According to Geometry, Cylindrical Pressure Vessels, Spherical Pressure Vessels, Conical Pressure Vessels,

According to Orientation: Horizontal Pressure Vessels, Vertical Pressure Vessels, Inclined Pressure Vessels, According to Installations, Fixed Pressure Vessels, Portable Pressure Vessels

According to Wall Thickness: Thin Walled Pressure Vessels, Thick walled Pressure Vessels.

Pressure Vessels Parts:

Vessel Body – Cylindrical or Spherical Shell.

Vessels Heads – Flat, Tori, Elliptical, Hemi Heads

Vessel Supports - Leg , Lug, Skirt, Saddle Supports

Vessel Nozzles & Man ways

What is Mean by Codes: Codes is nothing but set of Rules for the Design, Fabrication, installation, Inspection, and Testing of Industrial Process Plants and Equipment's.

What is Mean by Standards: It Consist of group of Rules Prepared by Professional People for the Design, Manufacturing and Pressure Integrity of the Components.

Principles of Pressure Vessel Codes : Safety, Constructability, Operability, Maintainability, Economy

ASME SECTION VIII – For Pressure Vessels : This Section Provides all Rules and requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels. It has Division - 1, Division – 2, Division – 3 three Devisions.

Pressure Vessel Code is revised and updated after interval of every three years and Addenda published annually

ASME SECTION II – For Materials : This Section Provides all details for Materials Part A – Ferrous Material Specifications, Part B – Nonferrous Material Specifications, Part C – Specifications for Welding Rods, Electrodes, and Filler Metals, Part D – Properties.

ASME SECTION V – For Non-Destructive Testing: This section describes for Requirements and methods for nondestructive examination which are referenced and required by other code Sections. It also includes manufacturer’s examination responsibilities, duties of authorized inspectors and requirements for qualification of personnel, inspection and examination. E.g – DPT, RT, UT, MPT.

ASME SECTION IX – For Welding Qualifications : This section provides Rules relating to the qualification of welding and brazing procedures as required by other Code Sections for component manufacture. It also Covers rules are related to the qualification and re-qualification of welders and welding and brazing operators in order that they may perform welding or brazing as required by other Code Sections in the manufacture of components

AWS – American Welding Society – For Welding - This Code is used for Welding Process, Welding Material, Welding Consumables and other Welding data

API – American Petroleum Institute - Storage Tanks -This Code is used for Storage Tank Fabrication. It Has API 620, API 650 Standards.

Piping Codes - ASME B 31.1 – Power Piping, ASME B 31.2 – Fuel Gas Piping, ASME B 31.3 – Process

Piping, ASME B 31.4 – Liquid Piping, ASME B 31.5 – Refrigeration Piping, ASME B 31.8 – Gas Transmission and Distribution Piping,

Pipe Standards - ASME B 36.19 – Stainless Pipes, ASME B 36.10 – Carbon Steel and Alloy Pipes

Fittings Standards - ASME B 16.10 – For SW and Screwed Fittings, ASME B 16.9 – For BW Fittings

Flanges Standards: ASME B 16.1 – Cast Iron Flanges, ASME B 16.5 – Forged Steel Flanges, ASME B 16.47 – Forged Steel Flanges for Big Bore Size

Bolts And Nuts Standards: ASME B 18.2.1 – Bolts, ASME B 18.2.2 - Nuts

Valves Standards: ASME B 16.34 For Valves, ASME B 16.10 Face to Face Dimensions

Gaskets Standards : ASME B 16.20 Metallic Gaskets, ASME B 16.21 Non Metallic Gaskets

Pickling Specification: SSPC – SP – 8 - 63

Link for Fabrication Useful Mobile App:

http://letsfab.in/our-apps/

Website: www.letsfab.in

Blogger Link: letsfab.blogspot.com

Facebook Page: @letsfab.in

#pressurevesselsfabrication

#pressurevesselscodes

#pressurevesselsstandards

#letsfab

Информация по комментариям в разработке