Within the domain of non-ferrous piping systems, the copper elbow stands as a critical component, engineered to fulfill a role where material properties are intrinsically linked to system function. Its purpose—to facilitate a directional change in flow—is universal, yet its execution in copper addresses a distinct set of performance criteria unmatched by many alternative materials. The value of a copper elbow is derived from a synergistic combination of inherent material characteristics: exceptional thermal conductivity, ensuring efficient heat transfer and uniform temperature distribution critical in heating, cooling, and refrigeration; proven antimicrobial properties, where copper ions actively inhibit biofilm formation, supporting water purity and system hygiene; and a predictable corrosion resistance, particularly in potable water systems, where a stable, adherent protective patina naturally forms. This unique profile makes the pre-fabricated copper elbow not merely a connector but a performance-defining element. Its precision-engineered geometry ensures a hydraulically smooth turn with a consistent bend radius, minimizing turbulence, pressure drop, and localized erosion—a feature paramount in high-velocity refrigerant lines or circulated water systems where efficiency is critical.

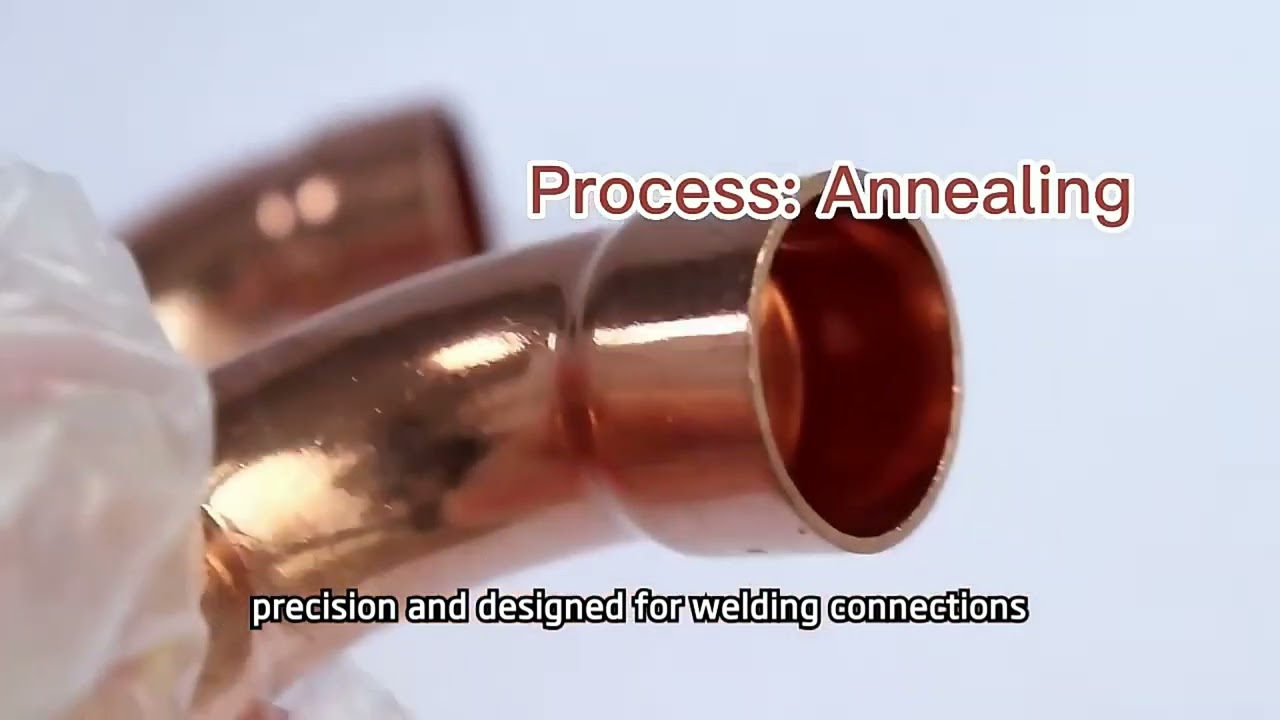

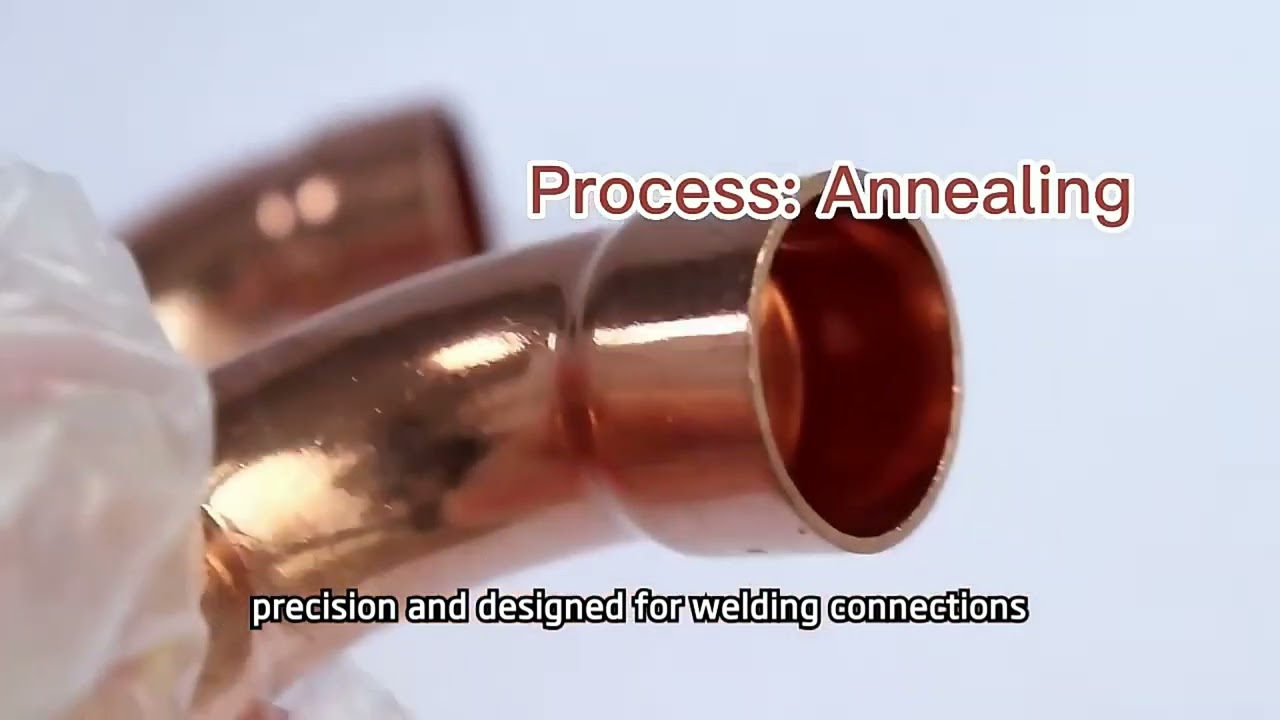

The manufacture of high-integrity copper elbows is a process that emphasizes material purity and joint reliability. They are predominantly produced from phosphorus-deoxidized copper (C12200), an alloy specifically formulated to resist embrittlement during the high-temperature brazing process essential for creating permanent, leak-free joints. Manufacturing techniques such as hot forging or precision extrusion are employed to create seamless fittings, ensuring a homogeneous grain structure and uniform wall thickness at the bend—the area most susceptible to stress and thinning. Post-forming, the fittings undergo meticulous finishing. The internal bore is cleaned and smoothed to achieve an optimal surface finish for flow efficiency, and the ends are precision-machined for the specific joining method. For capillary soldering in plumbing, solder-cup ends are standard, while square-cut, chamfered ends are prepared for the deep-penetration brazing required in HVAC/R and medical gas applications. This rigorous production ensures the fitting contributes no contamination, weakness, or flow restriction to the system.

The application of copper elbows is concentrated in industries where its material advantages are non-negotiable and often code-mandated. In HVAC/R systems, they are the undisputed standard for refrigerant linesets, valued for thermal performance, compatibility, and the hermetic integrity of brazed joints. Within potable water distribution, copper elbows form durable, long-lasting networks in residential, commercial, and institutional settings, directly contributing to water quality. Medical Gas Pipeline Systems (MGPS) in healthcare facilities rely exclusively on copper fittings, where absolute purity, safety, and joint reliability are critical for life-supporting gases. Furthermore, copper elbows are essential in solar thermal collectors, industrial heat exchangers, marine potable water systems, and specialized laboratory piping.

Selecting copper elbows represents a decision based on lifecycle value and proven performance. Compared to polymer-based systems (e.g., PEX), copper offers superior thermal conductivity, inherent flame resistance, greater mechanical strength, and a multi-decade service history. Against coated steel, it provides maintenance-free, inherent corrosion resistance in water services. The initial material cost is frequently justified by lower lifetime operating costs, reduced maintenance, and unparalleled system longevity. Specification requires careful selection of the tube type (e.g., Type L for plumbing, ACR for refrigeration), adherence to pressure ratings, and specification of the correct joining method, all governed by stringent standards such as ASTM B75, ASME B16.22, and NSF/ANSI 61.

In conclusion, the copper elbow is a component that embodies the principle of right material for the right application. It is a precision-engineered solution for systems where heat transfer, hygiene, durability, and joint integrity converge. Its continued, code-specified use in critical infrastructure—from cooling our buildings and delivering clean water to supporting healthcare—is a testament to its unmatched performance profile. The copper elbow thus remains a benchmark of reliability, a component where fundamental material science is directly translated into enduring system performance.#copper #elbow #factory #company

Информация по комментариям в разработке