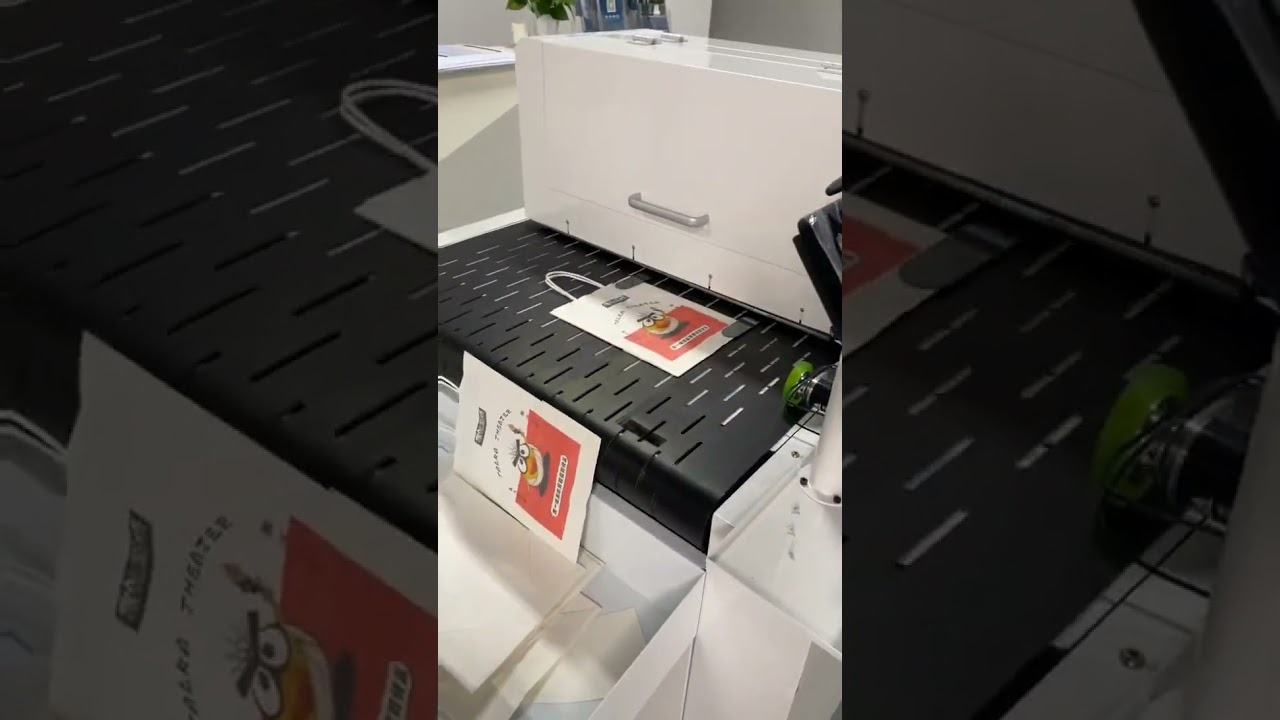

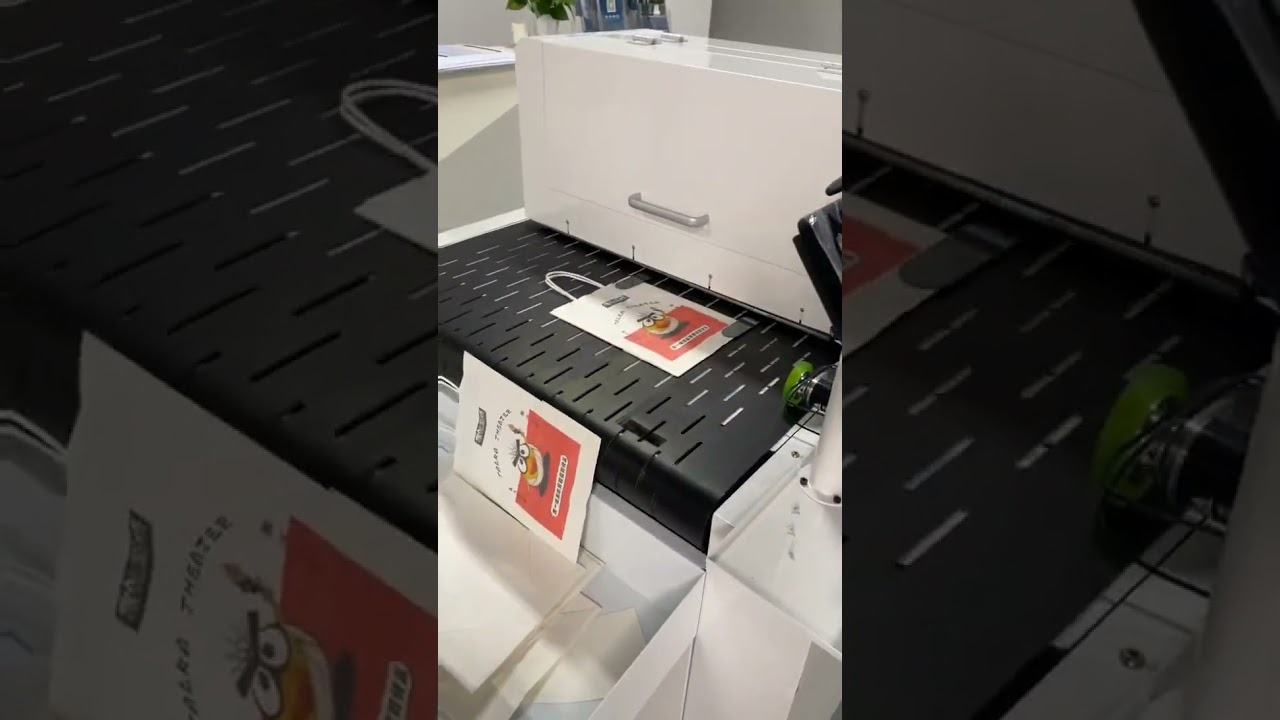

Shopping bag high-speed digital inkjet printer

Structural composition

• Automatic transmission system: usually composed of conveyor belt, deviation correction device, etc. The conveyor belt is responsible for smoothly transporting the shopping bag to the printing area, ensuring the transmission speed and position accuracy of the bag, and providing a stable foundation for subsequent printing. The deviation correction device can automatically adjust the position deviation of the shopping bag during the transmission process to ensure that the pattern can be accurately printed at the designated position of the shopping bag.

• Digital printing system: The core component is the nozzle, with high resolution, which can achieve richer color performance and more delicate pattern details. The ink supply system provides a stable ink supply to the nozzle to ensure the uniformity and continuity of the ink during the printing process. The nozzle drive mechanism controls the movement of the nozzle so that it can accurately spray the required pattern on the surface of the shopping bag.

• Control system: Generally equipped with a touch screen operation panel, the operator can intuitively set the printing parameters through the panel, such as printing speed, pattern size, color matching, etc. The control system can also monitor and diagnose the entire printing process. When an abnormality occurs, an alarm will be issued in time and a solution will be prompted to ensure the stable operation of the equipment.

• Curing system: UV curing technology is mostly used. After the printing is completed, the ink is quickly dried and cured by UV light, thereby improving production efficiency. The cured pattern has the advantages of wear resistance, scratch resistance, and no fading, which improves the quality and service life of the shopping bag.

Working principle

When working, the shopping bag is placed on the conveyor belt. The conveyor belt is driven by the motor to transport the shopping bag to the printing area at a uniform speed. The deviation correction device monitors and adjusts the position of the shopping bag in real time. When the shopping bag reaches the designated position, the nozzle, under the command of the control system, accurately sprays the ink onto the surface of the shopping bag according to the preset pattern and color information to complete the printing of the pattern. Subsequently, the shopping bag passes through the UV curing system, which makes the ink dry and solidify instantly, forming a firm and clear pattern, and finally outputs it through the conveyor belt to complete the entire printing process.

Advantages

• High printing quality: Digital printing technology can achieve high-precision pattern printing, with high resolution, rich colors, and natural transitions. It can meet the needs of various complex patterns and colors, making the patterns on the shopping bags more vivid and realistic, and enhancing the added value of the products.

• High production efficiency: The combination of automatic transmission system and high-speed printing technology greatly improves production efficiency. Shopping bags can be continuously transmitted and printed without manual intervention, reducing downtime in the production process, improving equipment utilization, and are suitable for large-scale production needs.

• Strong flexibility: No plate making is required, and single-piece printing can be achieved. The printing pattern and text information can be changed at any time according to the different needs of customers, meeting the requirements of personalized customization, providing enterprises with more design and production freedom, and reducing production costs and inventory pressure.

• Environmental protection and energy saving: In the digital printing process, there is no need to use plate making, plate washing and other processes in traditional printing, reducing the use of chemicals and wastewater discharge, and being more environmentally friendly. At the same time, UV curing technology does not require a long drying process, saving energy and reducing energy consumption in the production process.

Информация по комментариям в разработке