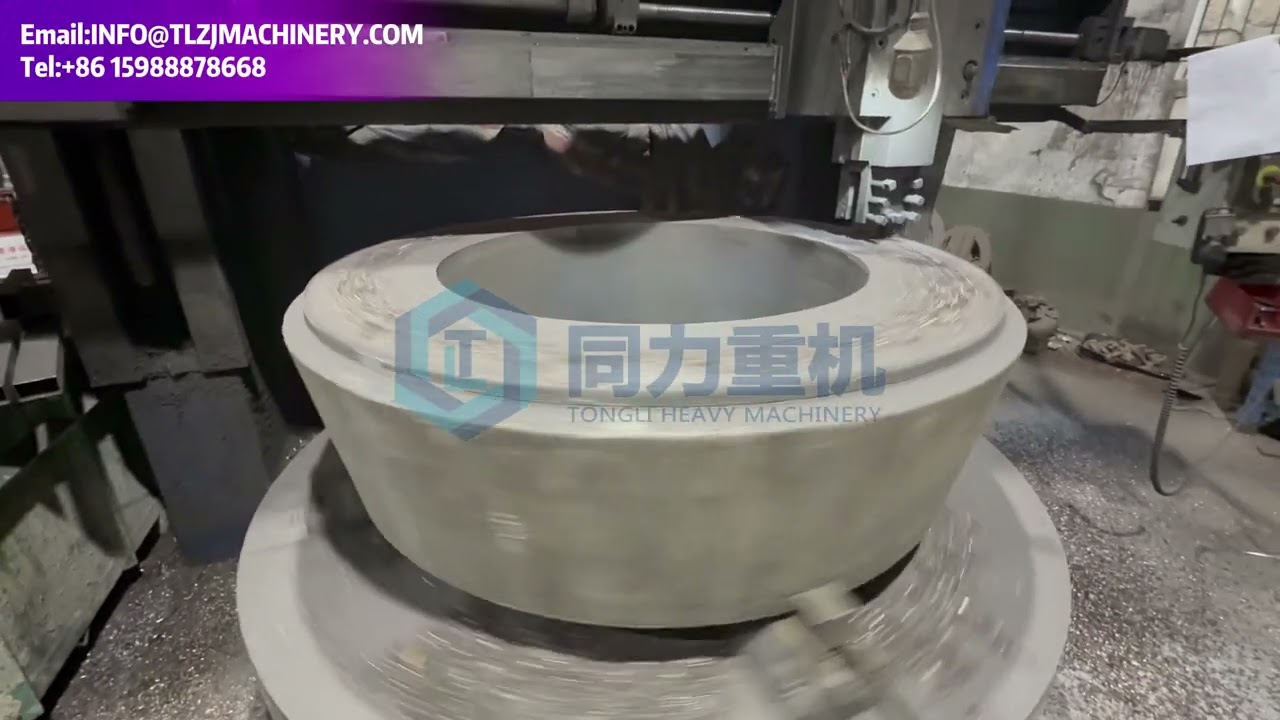

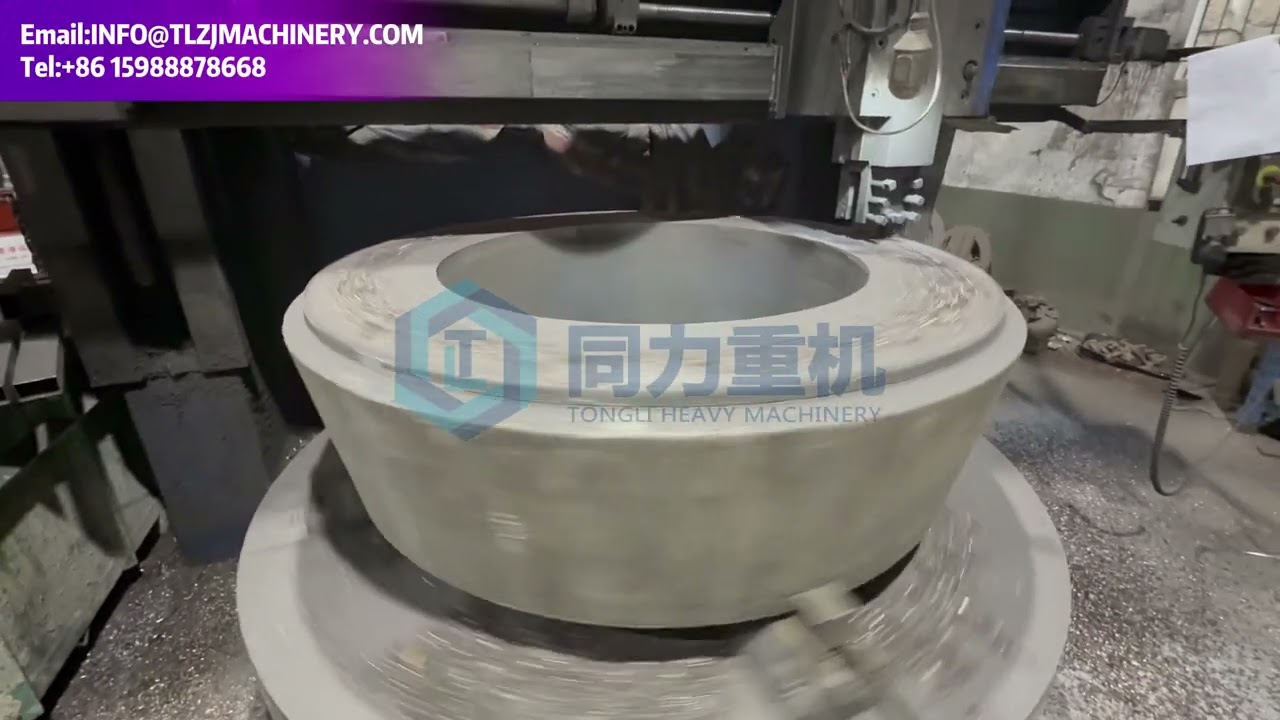

https://www.cementl.com/product/ceram... OEM Vega India TiC-reinforced ceramic–metal composite VRM liners produced by single-stage composite casting are designed to deliver high abrasion resistance, stable wear behavior, and long service life in vertical roller mills operating under severe grinding conditions. The liners are typically manufactured using high-chromium iron or alloyed cast iron (Cr 18–25%) with in-situ TiC ceramic reinforcement, achieving segment weights of 1.5–4.5 tons and effective wear layer thickness of 120–180 mm. In single-stage composite casting, titanium-bearing alloy additions are introduced directly during melting and pouring at 1480–1520 °C, allowing TiC particles to form uniformly within the wear zone during solidification. This process produces a dense ceramic–metal composite structure with surface hardness of HRC 62–65, good metallurgical bonding, and consistent wear performance, while maintaining a tougher backing matrix (HRC 38–45) to resist impact and thermal stress. Final OEM processes include controlled heat treatment, CNC machining, hardness mapping, ultrasonic testing, and dimensional inspection to ensure full interchangeability with Loesche, Pfeiffer, Polysius, and FLS vertical roller mill grinding table liner designs.

Single-stage Composite Casting

A manufacturing process where ceramic reinforcement (such as TiC) is formed in situ during a single pouring operation. Titanium-containing alloy elements react with carbon in the molten metal during solidification, creating fine TiC particles directly inside the wear layer. This ensures good dispersion, strong metallurgical bonding, and stable wear behavior.

One-step Composite Casting

Another term for single-stage composite casting, emphasizing that the composite structure is completed in one pouring and solidification cycle, without secondary casting or bonding steps. It offers simpler production control and lower manufacturing cost.

Primary Composite Casting

Refers to composite formation that occurs during the primary casting stage itself. The wear-resistant ceramic phase is generated as part of the base casting process, not added later. This term is often used to distinguish it from secondary or post-casting reinforcement methods.

In-situ TiC Reinforced Composite

A composite structure where TiC ceramic particles are formed internally within the molten metal through chemical reaction (Ti + C → TiC). Compared with ex-situ ceramics, in-situ TiC shows better interfacial bonding, lower risk of particle pull-out, and more uniform wear.

Two-stage Composite Casting

A more complex process where the ceramic-rich wear layer is produced first, followed by a second casting step to add a backing layer. The two layers are metallurgically bonded, allowing higher ceramic concentration and improved impact resistance, but with higher cost and longer production time.

Secondary Composite Reinforcement

Any reinforcement method applied after the primary casting step, such as secondary pouring, alloy bar embedding, or ceramic layer bonding. This approach is used to enhance local wear resistance or impact strength in critical zones.

Dual-layer Composite Structure

A liner structure consisting of a hard, ceramic-reinforced working layer and a tougher backing layer. The design balances wear resistance on the grinding surface with mechanical strength and crack resistance in the base.

Ceramic–Metal Secondary Bonding

A process where ceramic elements or ceramic-rich materials are bonded to a metal substrate during a secondary casting or joining step. Bond quality depends heavily on temperature control and interface cleanliness.

Ex-situ TiC Composite with Alloy Bar

A composite method where pre-manufactured TiC ceramics or TiC-reinforced alloy bars are physically inserted into the mold before pouring. While this can achieve very high local wear resistance, it carries higher risks of weak interfacial bonding compared to in-situ TiC formation.

#VerticalRollerMill #VRM #GrindingTableLiner #GrindingRollerSleeve #GrindingRollerLiner #VRMSpareParts #CementGrinding #RawMaterialGrinding #ClinkerGrinding #WearResistantParts #MillWearParts #HighChromiumLiner #CastAlloyLiner #Hardfacing #OverlayWelding #IndustrialGrinding #CementPlantEquipment #MiningEquipment #PowerPlantMilling #SteelPlantGrinding #LongServiceLife #HighWearResistance #OEMSpareParts #VRMGrindingSystem #VerticalMillParts

Информация по комментариям в разработке