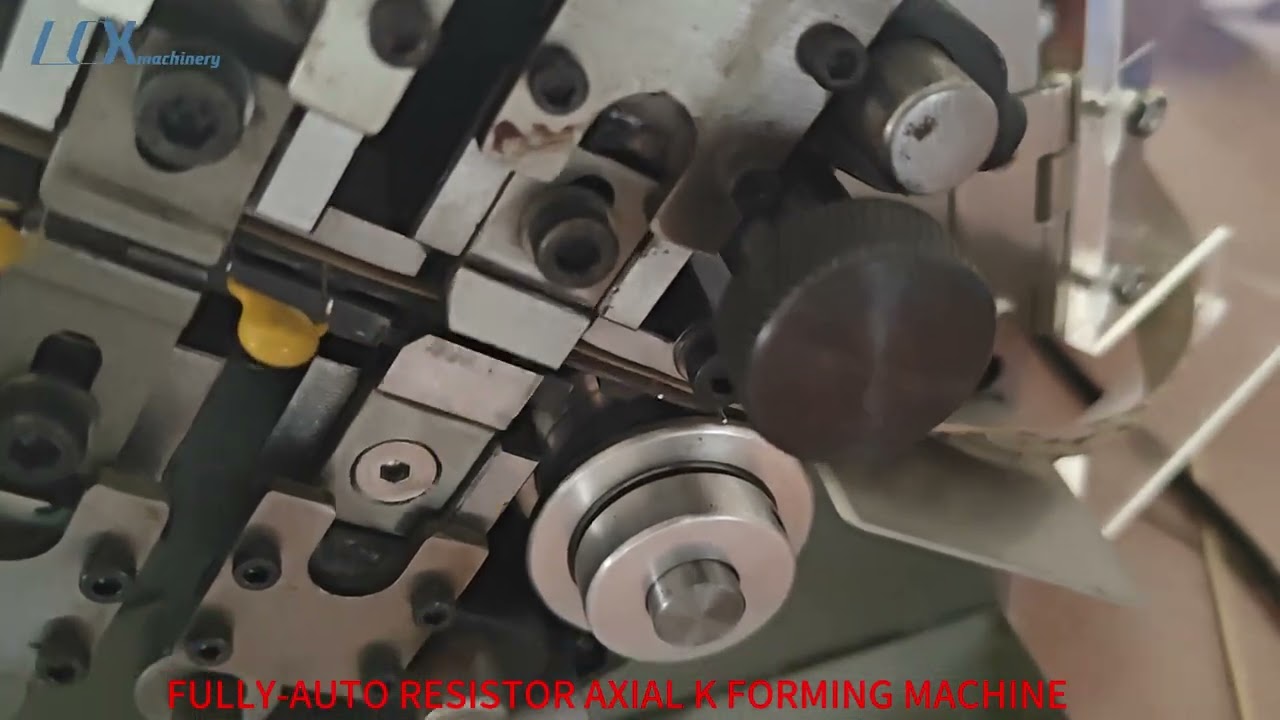

The Fully-Auto Resistor Axial K Forming Machine is a state-of-the-art, automated system designed for the high-precision bending and forming of axial lead electronic components, primarily resistors, into a specific "K" shape. This shape is crucial for correct insertion and optimal performance on printed circuit boards (PCBs) in various electronic applications.

Core Function & Purpose:

The machine automates the process of taking resistors with straight axial leads (wires extending from each end) and forming them into a standardized "K" bend configuration. This pre-forming ensures components fit securely into PCB holes with the correct spacing (lead pitch), improves placement accuracy for automated insertion equipment, and provides mechanical strain relief.

Key Features & Advantages:

Full Automation: The entire process—from component feeding and orientation to bending, forming, and ejection—is performed automatically without manual intervention. This significantly boosts production rates, consistency, and reduces labor costs.

High Precision & Consistency: Equipped with precision forming dies and guides, the machine ensures every resistor is bent to identical specifications. This eliminates human error and variation, guaranteeing uniform component quality and reliable PCB assembly.

High-Speed Operation: Engineered for industrial production lines, these machines can process thousands of components per hour, dramatically increasing throughput compared to manual or semi-automatic forming.

Versatility & Adjustability: Typically, the machine allows for easy adjustment of key parameters such as:

Lead Pitch: The distance between the two bent leads.

Bend Radius & Angle: The shape and geometry of the "K" bend.

Component Body Length: To accommodate different resistor sizes.

This flexibility enables quick changeovers for different product batches.

Robust & Reliable Construction: Built with durable materials and precision mechanics, it ensures stable, long-term operation in demanding factory environments with minimal downtime.

User-Friendly Operation: Modern versions often feature intuitive touchscreen interfaces (HMIs) for easy setup, monitoring, and control of forming parameters. Diagnostics and production data tracking are commonly included.

Integrated Safety: Includes safety guards, emergency stops, and sensors to protect operators and prevent damage to the machine or components.

Typical Workflow:

Feeding: Resistors are loaded into a vibratory bowl feeder or a stick magazine, which orients and delivers them correctly to the forming station.

Forming: The resistor is precisely positioned, and hydraulic or servo-driven forming tools apply force to the leads, creating the perfect "K" bend according to pre-set dimensions.

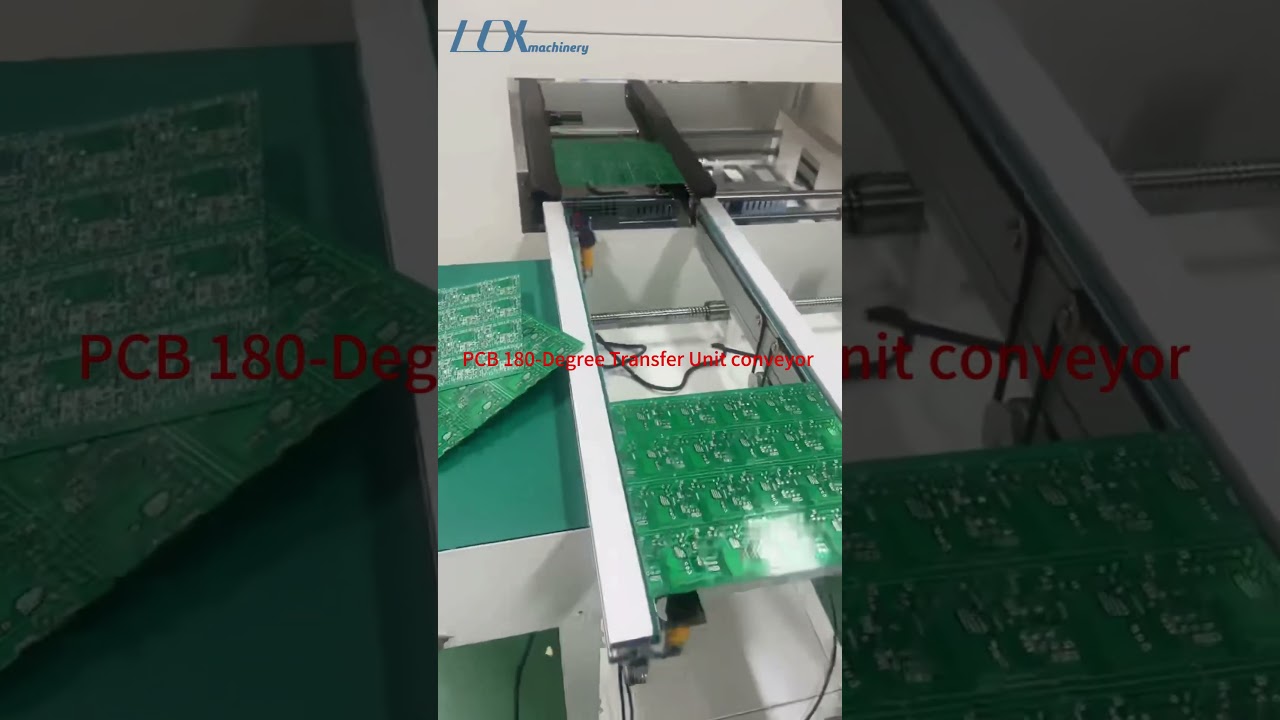

Ejection: The finished, formed resistor is automatically ejected into a collection tray or directly conveyed to the next stage of production.

Primary Applications:

Electronics Manufacturing: Mass production of televisions, audio equipment, power supplies, industrial controls, and automotive electronics.

PCB Assembly Services: Contract manufacturers (CMs) who require efficient preparation of components for auto-insertion machines or even manual assembly lines.

Resistor & Component Manufacturers: Companies that provide pre-formed axial components as value-added services to their customers.

In summary, the Fully-Auto Resistor Axial K Forming Machine is an essential piece of automation equipment for modern electronics manufacturing. It delivers unmatched efficiency, precision, and reliability in preparing axial lead components for circuit board assembly, enhancing overall production quality and speed.

Информация по комментариям в разработке