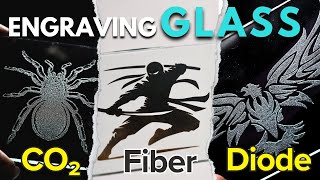

The video is talking the machine test of fiber laser glass engraving.

Our Store/Nuestra Tienda: https://spierlaser.en.alibaba.com

Contact: [email protected] +86-13335151833

Hi, I am Clara, is the fiber laser capable to engrave glass? Today we are going to do the test, the machine I used is a 20W fiber laser marking machine with 110mm field lens, let’s see what we can get today.

We did not do any treatment to the glass, no spray or paint. What we need for tests are a piece of stainless steel plate, a short glass plate, tin sticker, an aluminum plate, a piece of carbon steel plate and a piece of paper.

1: Let’s put the stainless steel plate under the glass. We need to find the focus first, it should be the focus to the stainless steel, not the glass. First try is at 1000 speed, 100 power and 0.05 hatch. It is too light, we can barely see any mark here, we need to slow down the speed. Second try is at 500 speed, 100 power and 0.05 hatch. It is still light, we can see a little white silhouette. Next let try 100 speed, 100 power and 0.05 hatch. We can see the dark engraving. We need to clean up the generated waste, I can feel the engraving curves to touch it. Let’s give it another try, 50 speed , 100 power and 0.05 hatch.

Cleaning up the waste, we can see the engraving is much fine, clear enough. Let’s see what left on the stainless steel, I believe it should be the metal waste generated by laser. Let’s clean it up. It is a repeated engraving, because we made 4 tests under different speeds. The two engravings on glass and stainless steel, colors are similar.

2: Let’s try to put the aluminum plate under the glass. We will keep the parameters the same, 50 speed, 100 power and 0.05 hatch. It seems okay, let’s clean the waste. I feel heating when touching the engraving. It is a good engraving, but the color is different, it is light gray. Let’s see the aluminum plate, there is a lot of waste. The colors of two engravings are also similar.

3: Put the carbon steel plate under the glass. We will keep the parameters the same, 50 speed, 100 power and 0.05 hatch. It is also fairly fine. I can feel heating and engraving curves by touching it. The color is changed again, it is like the metal rusty color, similar to what shown on the carbon steel plate.

4: Let’s try to put a piece of paper under the glass. We will keep the parameters the same, 50 speed, 100 power and 0.05 hatch. It is likely to be out of quality, I can not remove the waste by paper rubbing. And the paper is burnt to cut directly and even leak the laser to the bottom metal.

5: I also tried to engrave the tin sticker, it is failed. The laser can not leave marks at the glass bottom.

To summarize the tests we did today.

1: The fiber laser can not function well directly on glass. The glass I used today is the normal one for windows, so I can not say it is confirmed 100%. If you do suggest to test other glass, please write it in the comment, I will try to make the test.

2: It is pure physical effect of fiber laser for glass. When we put the metal plate under glass, the laser will go through glass and engrave the metal directly. The metal shavings generated by the instantaneous high temperature of the laser will react on the lower surface of the glass, resulting in a physical stripping effect. So we will see the waste, actually they are many small metal particles, left on the surface of metal and glass.

3: The glass engraving will change colors as the bottom items, we can see the engravings differences.

4: It is physical effect, so the glass surface is damaged for sure. What I can say is the thicker the glass the better the engraving.

5: If you need to engrave glass like this way by fiber laser, metal bottom is best and choose the parameters for deep engraving.

So the conclusion is the fiber laser can not engrave glass directly, we need to ask help from some assistance. Do you have other confusions on laser marking machine? Please write it in the comment. Thank you for joining me today, you can subscribe me here for more videos. I will see you next Tuesday here on my YouTube channel, see you, bye.

Информация по комментариям в разработке