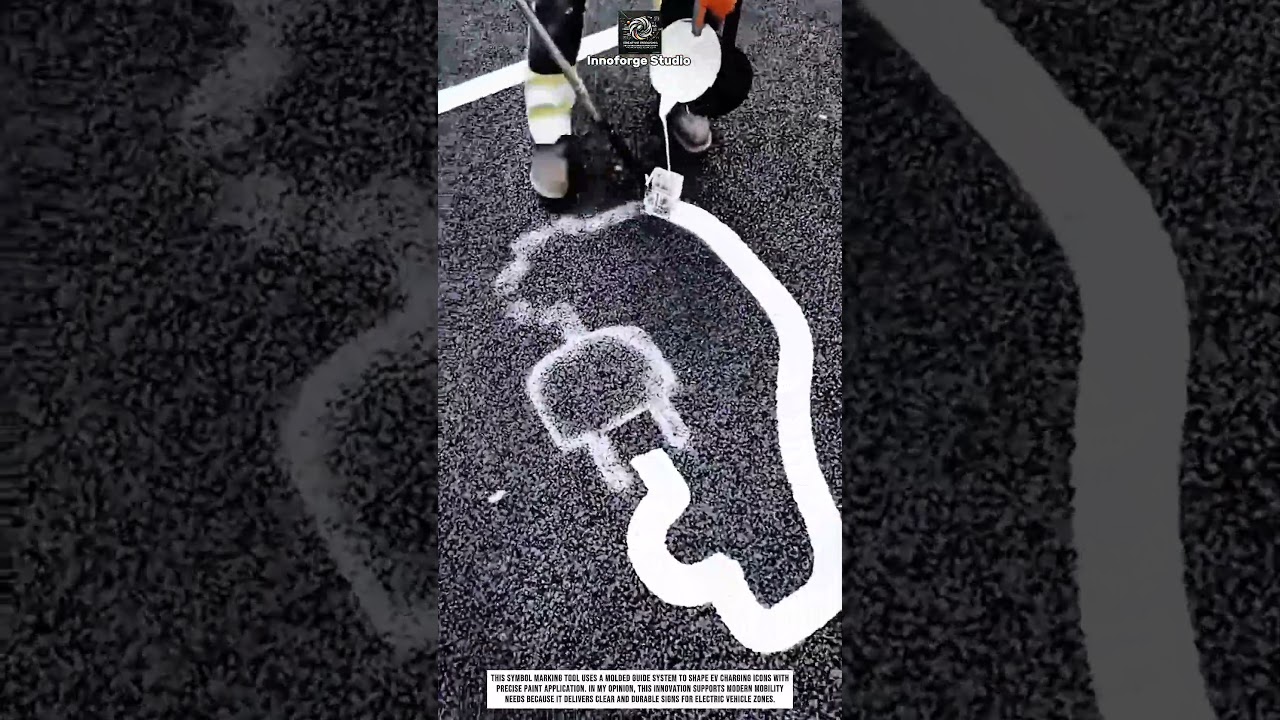

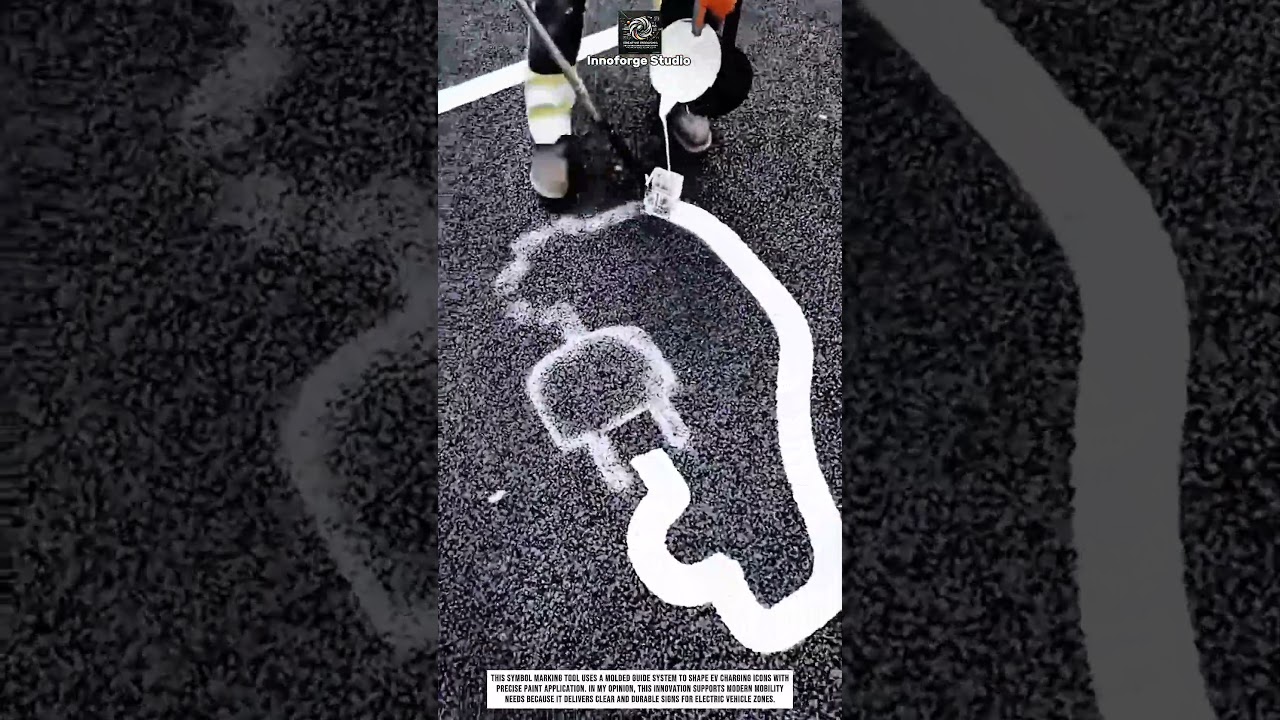

Road Painting Tool Innovation with Symbol Mold System for EV Charging Marks

Technical Specifications

Heavy-duty symbol mold designed for EV charging icons

Heat-resistant material suitable for thermoplastic or liquid paint

Precision pouring container with controlled flow

Manual guiding stick for stabilizing the mold position

High-visibility marking paint engineered for asphalt adhesion

Mold locking edges to prevent paint bleeding

Compatible with reflective bead application

Ergonomic handle system for safe and steady pouring

How It Works

This marking system utilizes a specialized mold shaped exactly like an EV charging icon. The operator positions the mold securely on the asphalt surface, aligning it with pre-drawn guide points to ensure accuracy. Once aligned, the operator pours thermoplastic or high-durability road paint into the cavity of the mold. The edges of the mold act as barriers, preventing overflow and maintaining crisp shapes. As the paint settles, it forms the outline and internal structure of the EV symbol. After a brief curing period, the mold is lifted, revealing a clean, recognizable marking suitable for parking areas, charging stations, and urban mobility zones.

Advantages

The mold system produces highly consistent results, ensuring that each EV symbol looks identical across multiple installations. This level of uniformity is essential for public understanding and compliance, especially as electric vehicle infrastructure grows. The process is simple yet highly precise, making it ideal for small and large projects alike. It allows crews to deploy modern road symbols quickly without relying on costly, machine-based stencil systems. The method supports both thermoplastic and durable cold paint, giving teams flexibility depending on project needs. It is also effective on newly paved surfaces where clarity and adhesion are critical.

Disadvantages

While practical, the system requires careful handling to prevent paint from overflowing the mold edges. Operators must pour at a steady pace to avoid uneven thickness or pooling. The mold must be cleaned regularly to prevent dried material from affecting future shapes. Because this method is manual, it may be slower for large-scale projects that require hundreds of symbols. Wind, uneven surfaces, or wet pavement can also interfere with accuracy, requiring additional preparation.

Impact on Productivity

Despite its manual nature, this tool significantly improves productivity when installing modern road symbols, especially in EV charging areas, parking zones, and commercial facilities. Crews can produce high-quality markings without expensive automated systems, reducing overall project cost. The mold ensures precise shapes each time, decreasing rework and minimizing time wasted on corrections. The ability to deliver consistent results with lightweight equipment allows teams to move quickly between sites, improving workflow efficiency. Over the long term, clearer EV markings support better traffic flow and user understanding.

Best Use Cases

This tool is ideal for electric vehicle parking spots, public charging stations, mall and office EV bays, municipal EV infrastructure, and private facilities supporting electrified fleets. It works effectively on asphalt, concrete, and newly resurfaced areas. Road maintenance teams, parking operators, and sustainability-focused facilities benefit greatly from using this system.

Like, comment, and subscribe to support more insights on tools and technology.

#innovation #tool #toolinnovation #technology #machine

Good tools and technology make work more enjoyable.

Regards,

Innoforge Studio

Информация по комментариям в разработке