Accelerated Solvent Extraction (ASE), also known as Pressurized Liquid Extraction (PLE) or Pressurized Solvent Extraction (PSE), is a modern and automated sample preparation technique used to extract organic compounds from solid and semi-solid matrices.

Principle:

The core principle of ASE relies on using common liquid solvents at elevated temperatures and pressures to enhance extraction efficiency and speed. Here's how these conditions contribute to effective extraction:

Elevated Temperature:

Increased Solubility: Higher temperatures significantly increase the solubility of analytes in the extraction solvent.

Faster Diffusion Rates: Molecules move more rapidly at higher temperatures, leading to quicker diffusion of analytes from the sample matrix into the solvent.

Reduced Solvent Viscosity and Surface Tension: The solvent becomes less viscous and has lower surface tension at elevated temperatures. This allows the solvent to penetrate deeper into the pores of the sample matrix and "wet" the sample more effectively, improving contact with the analytes.

Weakening of Analyte-Matrix Interactions: High temperatures disrupt the forces holding analytes to the sample matrix (e.g., van der Waals forces, hydrogen bonding, dipole attractions), making it easier for the solvent to dissolve and remove them.

Elevated Pressure:

Maintains Liquid State: Applying high pressure keeps the solvent in its liquid state even when its temperature is well above its normal atmospheric boiling point. This is crucial for achieving the benefits of high temperature without the solvent boiling away.

Enhanced Penetration: The increased pressure forces the solvent into the tiny pores and crevices of the sample matrix that would otherwise be inaccessible, ensuring more thorough contact with the trapped analytes.

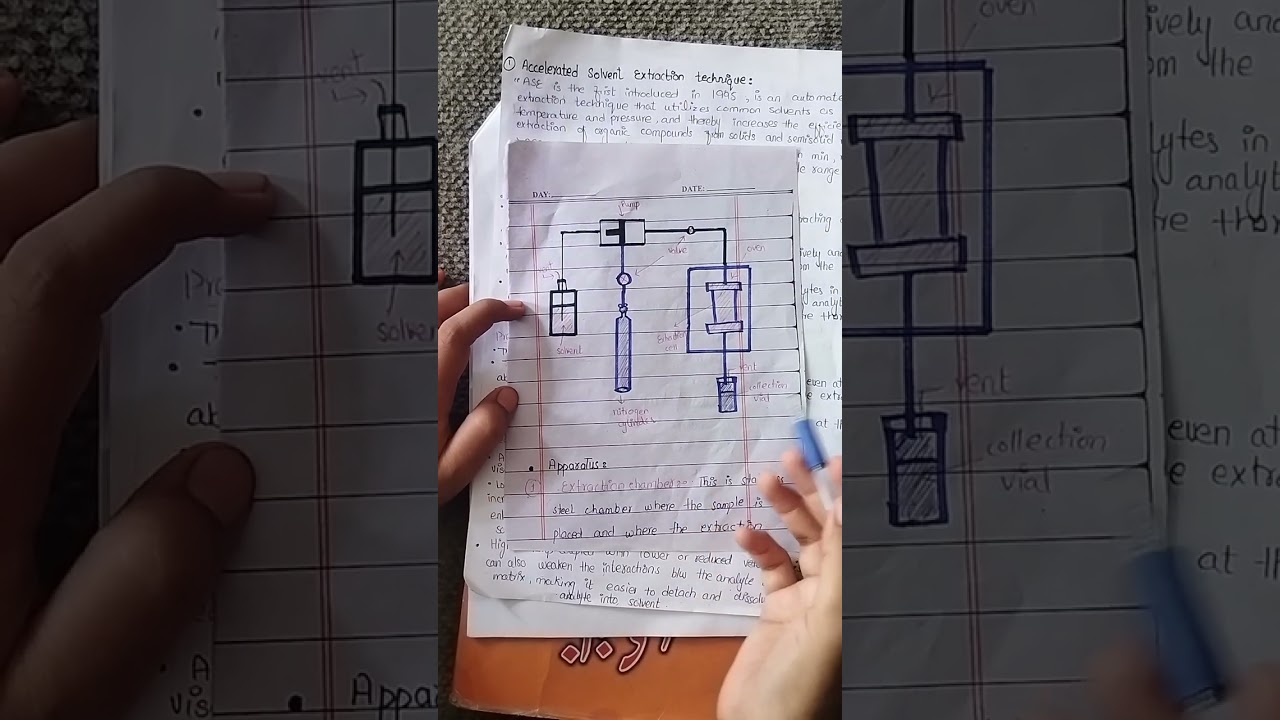

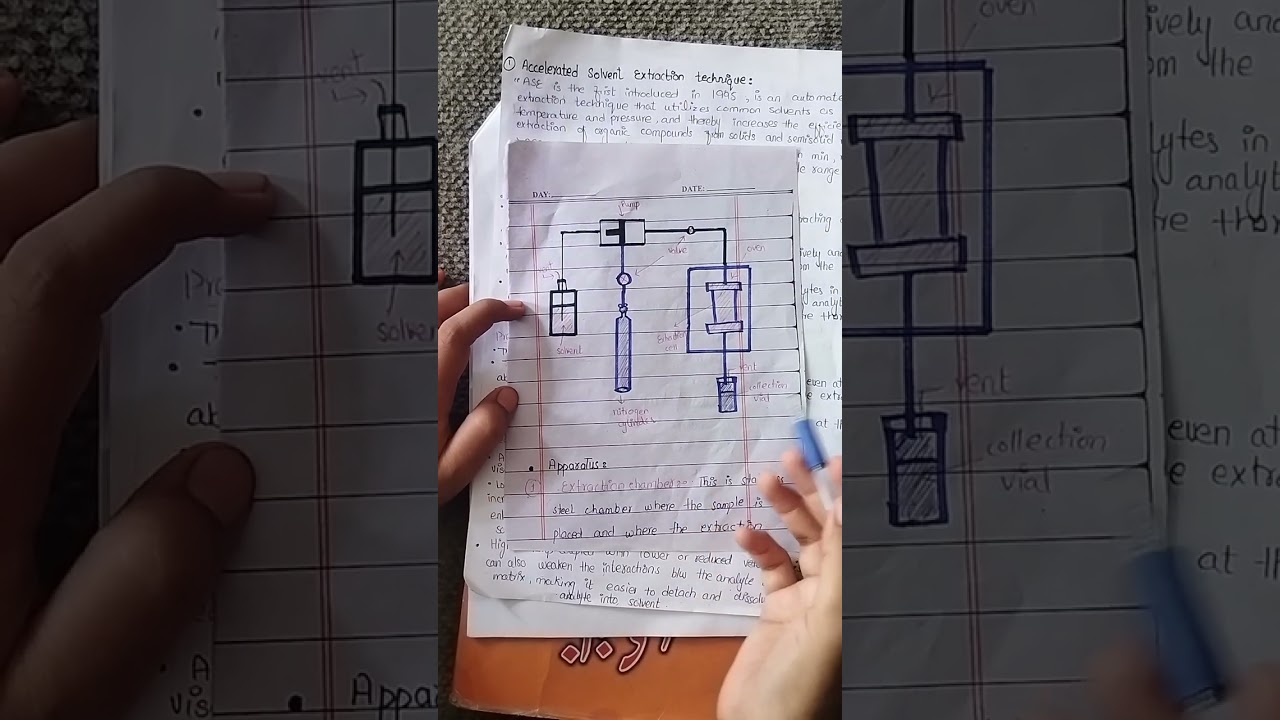

How it Works (General Process):

Sample Loading: A solid or semi-solid sample is placed into a specialized extraction cell (often stainless steel).

Solvent Delivery: The chosen extraction solvent (organic or aqueous) is pumped into the extraction cell.

Heating and Pressurization: The cell, with the sample and solvent, is heated to the desired elevated temperature (typically 50-200 °C) and pressurized (e.g., 500-3000 psi). The system maintains these conditions for a short "static" extraction period (usually 5-10 minutes).

Static Cycles (Optional): Some methods may include multiple static cycles where fresh solvent is introduced to further enhance extraction.

Flushing and Purging: After the static extraction, the extract containing the analytes is flushed from the cell into a collection vial. Compressed gas (e.g., nitrogen) is then used to purge any remaining solvent and analytes from the cell.

Collection: The extracted analytes, dissolved in the solvent, are collected in a vial, ready for further analysis (e.g., chromatography).

Advantages:

Reduced Extraction Time: Extractions are typically completed in minutes (e.g., 15-30 minutes) compared to hours for traditional methods like Soxhlet extraction (8-10 hours).

Lower Solvent Consumption: ASE uses significantly less solvent (e.g., 10-30 mL per sample) than conventional techniques, leading to cost savings and reduced waste.

High Efficiency and Recovery: The combined effect of elevated temperature and pressure leads to more exhaustive and efficient extraction of analytes from complex matrices, resulting in high recoveries.

Automation: ASE systems are typically automated, allowing for unattended operation and processing of multiple samples, which increases sample throughput and reproducibility.

Versatility: It can be applied to a wide range of solid and semi-solid samples, including environmental samples (soils, sediments), food products, natural products, polymers, and more.

Cleaner Extracts: In some systems, in-cell cleanup or filtration steps can be incorporated to reduce co-extracted matrix components, leading to cleaner extracts for downstream analysis.

Meets Regulatory Standards: ASE is accepted by various regulatory bodies, such as US EPA Method 3545A, for the extraction of various contaminants.

Disadvantages:

High Initial Cost: The equipment for ASE can be expensive, which might be a barrier for some laboratories.

Potential for Co-extraction: While in-cell cleanup helps, the aggressive conditions can sometimes lead to the co-extraction of interfering compounds, requiring additional cleanup steps.

Method Development: Optimizing parameters (temperature, pressure, solvent type, static time, cycles) for new applications can require some method development.

Limited to Solid/Semi-solid Samples: ASE is not suitable for direct extraction of liquid samples

@ChemistryZone809 .#acceralatedsolventextraction #acceleratedsolventextraction(ase) #acceleratedsolventextraction #acceleratedsolventextractor #acceralatedsolventextractionand #acceleratedsolventextractionandionexchangechromatography

Информация по комментариям в разработке