Fully automated Paint Repair process by accell GmbH (system integrator) that defines a new benchmark. The SSP-system stands for Scan, Sand, Polish.

During the painting of plastic parts, car bodies or other surfaces, visible defects usually occur in the paint (e.g. due to dust particles). Until now, these were removed with exhausting, time-consuming manual work. Depending on the feeling of the employees during the day, the result could vary. In addition, the strenuous activity (ergonomics and sanding dust = 3D jobs) is a burden for the skilled workers performing the work. A robotic system will allow you to automate this important and critical step in your manufacturing process.

In cooperation with experienced application experts from the respective specialist areas, the system integrator accell GmbH can provide you with a fully automated paint defect detection, sanding and polishing ready-to-use system - tailored to your specific needs. The SSP-system. Scan, Sand, Polish for perfect results. Automating this can help to improve consistency and productivity, and provides longterm cost savings.

The SOLUTION is a fully automated process of Scanning, Sanding and Polishing.

THE 3 STEPS:

1) DEFECT DETECTION + CLASSIFICATION

A camera system from ISRA VISION is used for defect detection. It is equipped with a new sensor that detects and classifies even the most inconspicuous type of defect. The stored coordinates of the defect are later used for exact identification during path programming. All sources of defects on the clear coat surface are simultaneously kept in statistics in order to evaluate the different defect characteristics during the course of the day. This makes it possible to continuously optimize the general conditions in the line and to minimize the error rate.

2) PATH PROGRAMMING

AUTOMAPPPS reactive planning Software (by Convergent Information Technologies GmbH) is used for the automatic path planning with the coordinates of the ISRA system.

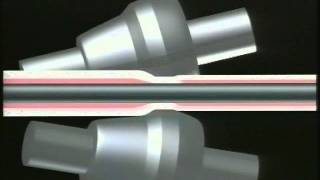

3) SANDING AND POLISHING - 2-IN-1 PACKAGE SOLUTION

The FerRobotics ACTIVE ORBITAL KIT XS Double Header (EOAT: End-of-Arm Tool) operates two tools on one robot quickly and efficiently without any device change. It is another intelligent system package of a specially designed electric random orbital sander/polisher based on the patented Active Compliant Technology (Trademark). Especially the industrial sanding and polishing process in partial paint repair benefits from this integrated ready-to-use solution since the system achieves a structure-free surface processing of all materials robot-compatible.

The very UNIQUE FEATURE is that the applied contact pressure is continuously validated in real time by innovative, redundant force monitoring via sensors and a conditioned calculation model. This enormously durable end-of-arm tool is ideal for industrial use and delivers twice the output of standard devices – 24/7. However, the double header impresses with reacting extremely fast and highly sensitive due to a light and compact design. All critical parameters, such as rotation speed, contact and process force as well as feed rate, may be individually controlled, thus enabling 100% process control. A fully integrated servo motor provides the drive. The AOK XS Double Header requires little maintenance and is universally compatible with many abrasives.

Surface treatment: sanding, grinding, polishing, cleaning

All materials: Plastic, steel, aluminum, titanium, magnesium, carbon, wood, ceramics,...

Proven application fields are of course in the automotive sector and related supply industry, as well as for electrical appliances, in mechanical engineering and in the furniture industry.

CREDITS:

accell GmbH - https://www.accell.at/paint-repair-sc...

ISRA Vision - www.isravision.com

Convergent Information Technologies GmbH - www.convergent-it.com/

IDENT Beratung & Handel - www.ident-beratung.de/en/

FerRobotics - https://www.ferrobotics.com/en/news/2...

Interested parties are welcome to register for one of the upcoming LIVE presentations or webinars.

FREE DEMO: https://www.accell.at/paint-repair-sc...

#bodyshop #paintshop #paintrepair

For more information contact our experts in your specific region:

https://www.ferrobotics.com/en/contac...

…

FEATURED PRODUCT: https://www.ferrobotics.com/en/servic...

…

VIDEO CREDITS: www.ferrobotics.com

Subscribe to our CHANNELS now and become part of the FerRobotics COMMUNITY:

👉 / ferrobotics

👉 / ferrobotics

Discover FerRobotics products: https://www.ferrobotics.com/en/servic...

![Аэрогель — самый легкий твердый материал [Veritasium]](https://i.ytimg.com/vi/846IEih2kX8/mqdefault.jpg)

Информация по комментариям в разработке