Automatic Condenser Tube Cleaning System (ACTCS) Using Balls

Overview:

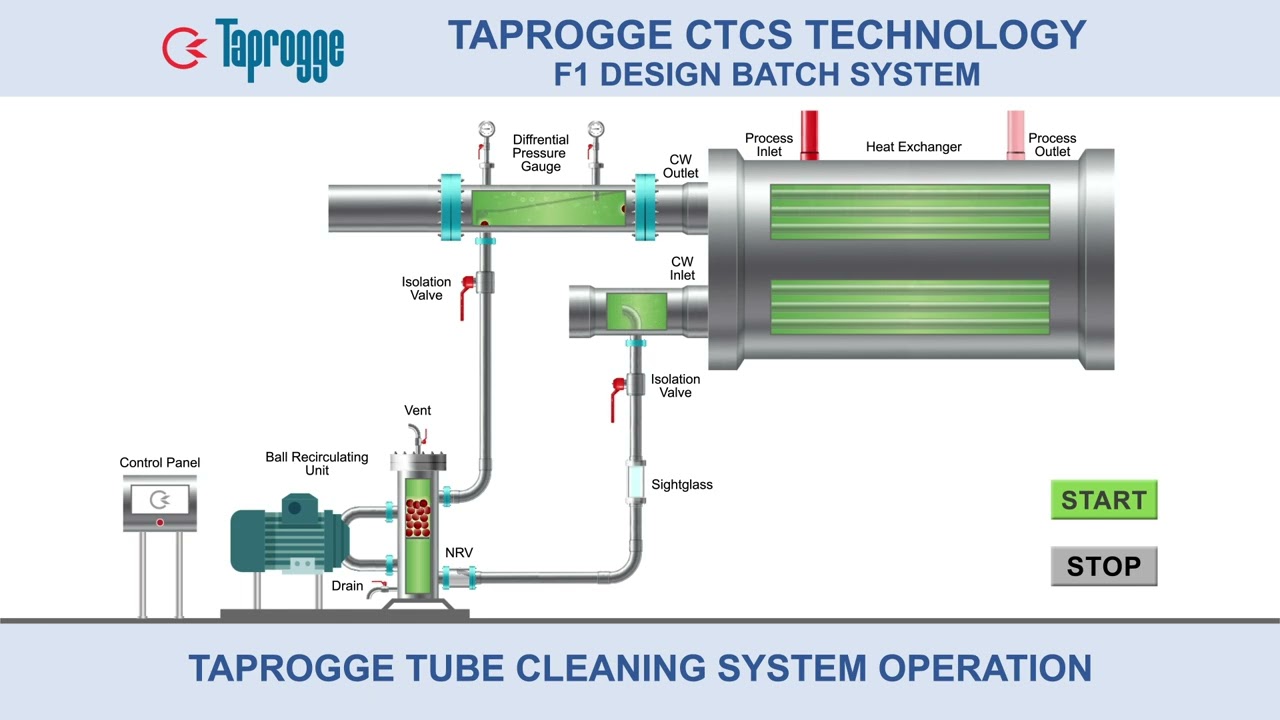

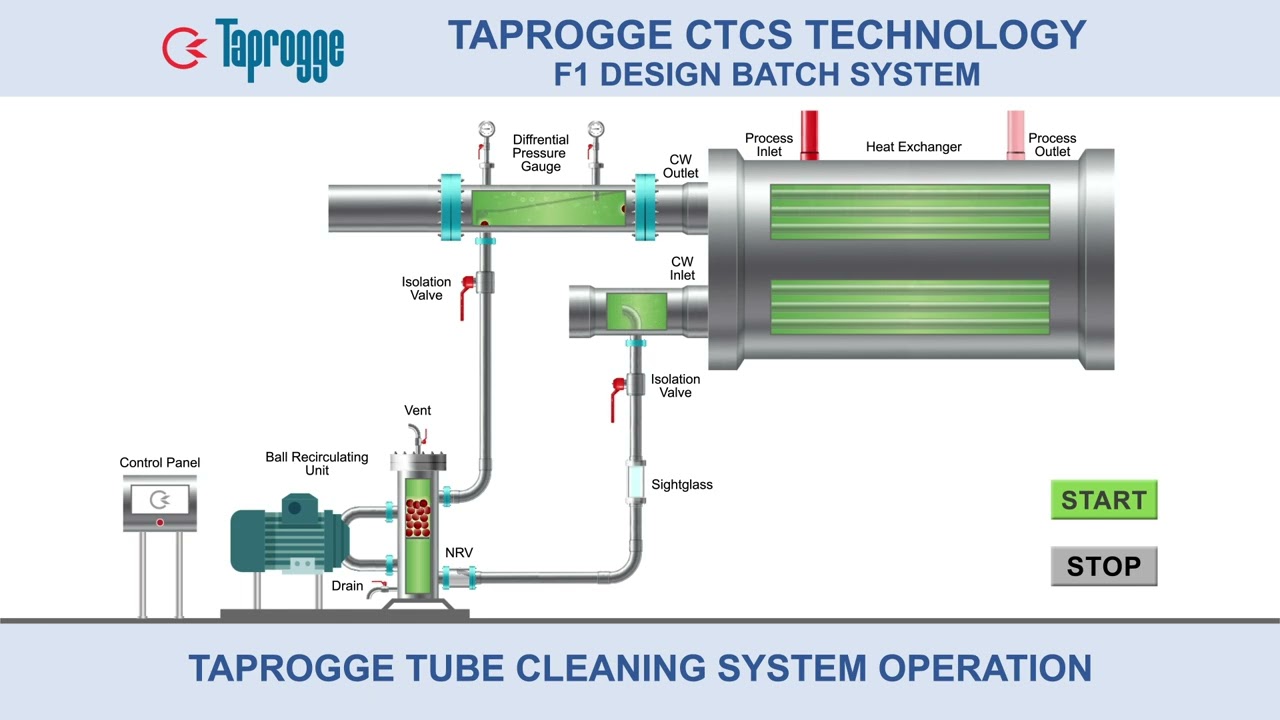

The Automatic Condenser Tube Cleaning System (ACTCS) is an advanced, eco-friendly solution designed to maintain the optimal thermal efficiency of shell and tube heat exchangers, condensers, and chillers in power plants, refineries, petrochemical plants, and HVAC systems. This system utilizes specially engineered cleaning balls that continuously clean the inner surfaces of heat exchanger tubes, effectively preventing fouling, scaling, and biofouling—thereby ensuring maximum heat transfer efficiency and reduced energy consumption.

Key Features:

Continuous Online Cleaning: Operates without the need to shut down the system, maintaining consistent heat exchanger performance.

Specialized Cleaning Balls: Elastomer balls (sponge, silicon, or rubber-based) slightly larger than the tube diameter scrub the inner tube walls as they pass through.

Closed-Loop Recirculation: Cleaning balls are injected into the condenser inlet, travel through the tubes, and are collected by a strainer and re-injected using a ball circulation pump.

Customizable Ball Composition: Available in various hardness levels and coatings to target specific deposits (e.g., biofilm, scale, algae).

Automatic Control System: PLC-based controls allow for customizable cleaning cycles, diagnostics, and remote monitoring.

Benefits:

Improved Thermal Efficiency: Maintains optimal heat transfer rates by preventing fouling-related thermal resistance.

Reduced Energy Costs: Enhances overall system efficiency, resulting in significant energy savings.

Lower Maintenance Costs: Minimizes the need for chemical cleaning, mechanical downtime, and manual labor.

Extended Equipment Life: Reduces corrosion and tube wear caused by deposits and frequent cleaning.

Environmentally Friendly: Reduces chemical usage and water wastage associated with conventional cleaning methods.

Technical Specifications:

Parameter Specification

Tube Diameter Range 10 mm – 50 mm

Ball Material Polyurethane, Rubber, Silicone, Composite

Ball Size 1–2 mm larger than tube inner diameter

Control System PLC with HMI/SCADA integration

Pump Type Centrifugal or Peristaltic (as per application)

Strainer Type Stainless Steel Ball Collector with Auto Flush

Power Supply 220V / 380V / 440V, 3-Phase, 50/60 Hz

System Compatibility Shell and tube heat exchangers, condensers

Applications:

Thermal Power Plants

District Cooling Systems

Petrochemical and Refinery Cooling

HVAC Systems in Commercial Buildings

Desalination Plants

Industrial Refrigeration Systems

Compliance & Standards:

Complies with ASHRAE, ISO 9001, and environmental regulations related to water and energy conservation.

Информация по комментариям в разработке