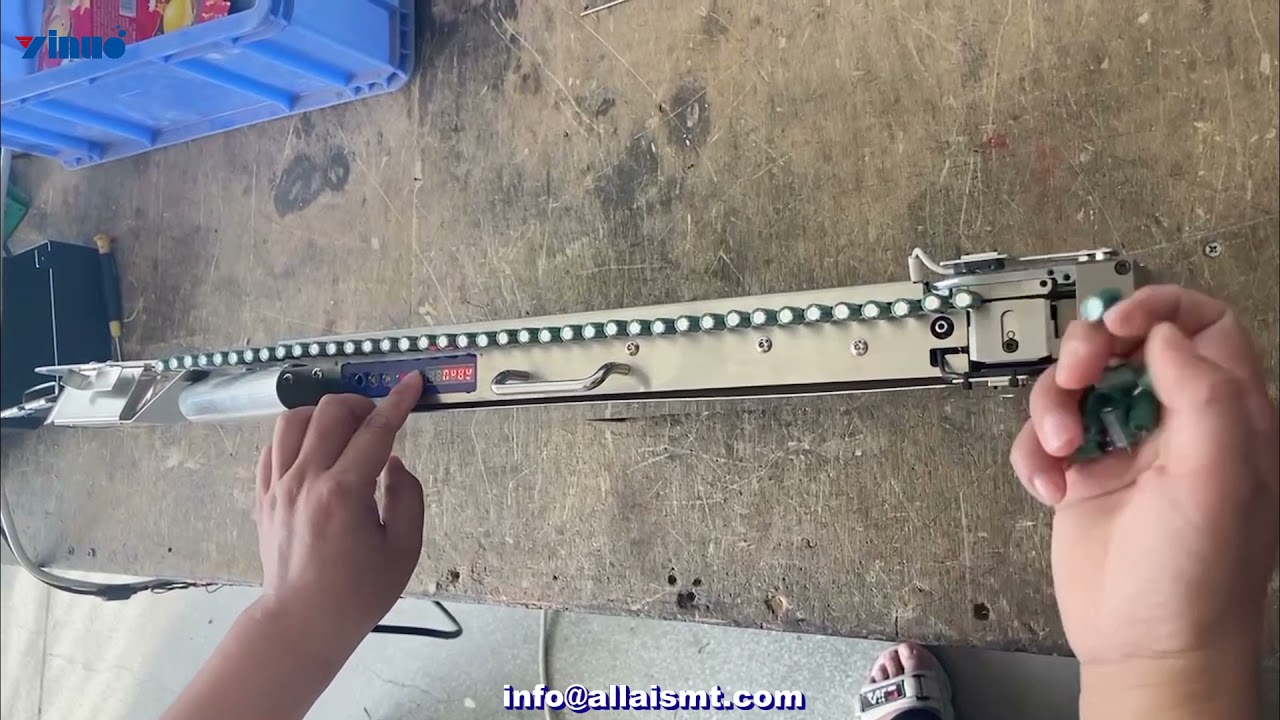

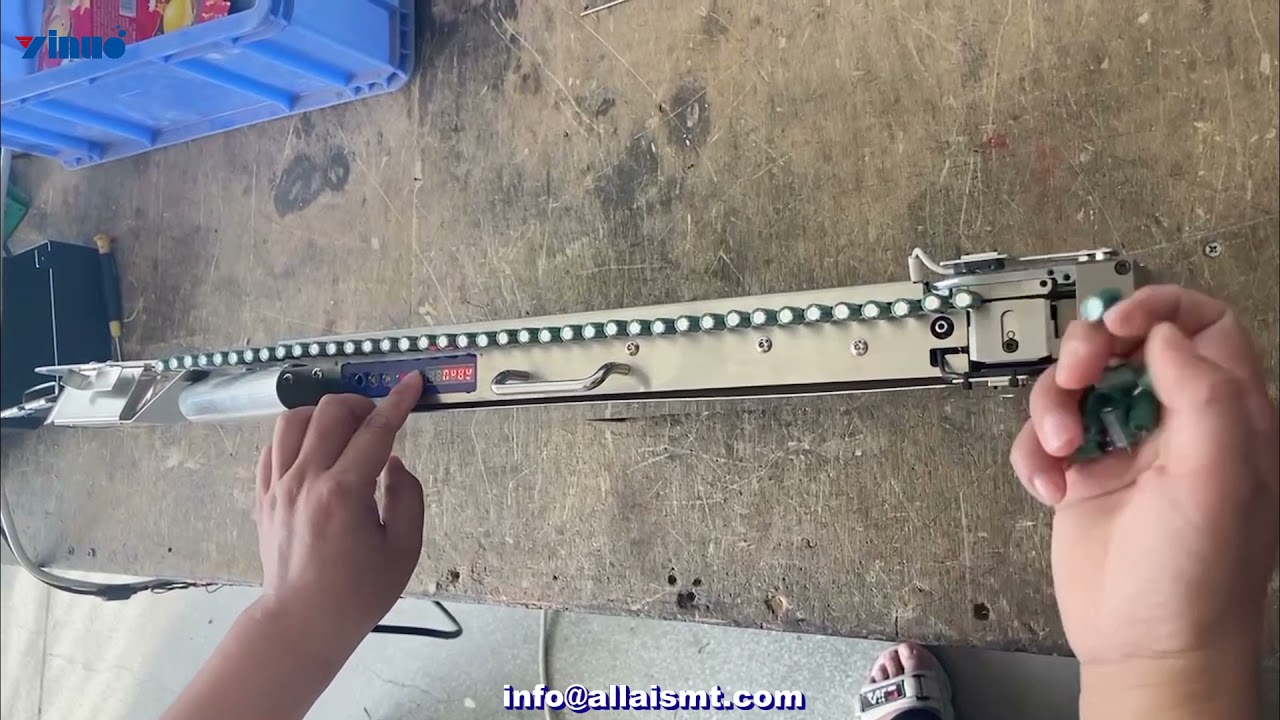

Radial tape feeder process include feeding the tape,cutting and 90 degree bending the radial component,it can as SMT insertion component feeder use to connect the SMT component insertion machine for automated pick up,also can as the taped component feeder to hold the component for robot application,This radial component feeder developed for the customer required,The complete process takes about 3 seconds. When the pliers pick up the part from the cutting component feeder, then it starts with another component.

Radial tape feeder Features:

Integrated lead cutting and bending component feeder unit

Wide component range

Easy adjustment

Excellent price-performance ratio

Intelligent communication with placement system

Easy user interface

With PLC control system

Feeder of SMT mount machine is generally used for mount components to supply components to use, and there are many types of Feeder, we need to choose according to their own needs.

I. According to the type and model of the SMT machine to choose.

1. Feeder type: Feeder can be divided into paper belt and tape Feeder. The difference is that the paper bag feeder has a needle. The tape feeder has no needle and only a belt guide.

2. Feeder model: generally divided into 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm, etc., we choose the appropriate Feeder according to the needs of components.

3. Type of mount machine: high speed mount machine, universal mount machine, electric mount machine;

Discriminant methods: high-speed veneer feeder without catheter, universal veneer feeder with catheter, electric veneer veneer feeder.

II. The hole position identification of the SMT

1. The position of the flying hole of the mount machine refers to the distance between the two points of the outer ring of the flying gear, which is 2mm and 4mm respectively. The spacing of 4mm is suitable for materials with specifications greater than or equal to 0603. However, the 2mm pitch is only suitable for 0402 specification materials.

2. Label identification of Feeder: the label is marked with the model number and number of Feeder. For example, MV8 4 -- 0001: MV refers to the arrival of high-speed SMT machine; 84 refers to the specifications of the placing machine, where 8 represents the packing width of the material and 4 represents the distance between the materials of the placing machine. 0001 represents the serial number of the mount machine.

YINUO provides a full SMT assembly line solutions, including SMT reflow oven, wave soldering machine, pick and place machine, solder paste printer, PCB loader, PCB unloader, chip mounter, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, SMT assembly line equipment, PCB production Equipment SMT spare parts, etc any kind SMT machines you may need, please contact us for more information:

Yinuo Electronics Co., Limited | Shenzhen,China

Email: [email protected]

Phone/Whatsapp: +86 18820465640

Wechat: 18820465640

Информация по комментариям в разработке