Join this channel to get access to perks:

/ @chrisvscars

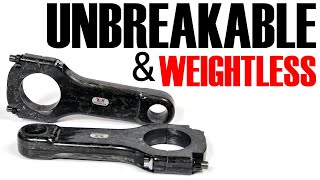

As technology continues to advance, engineers and manufacturers are constantly searching for ways to make products lighter, stronger, and more efficient. This is particularly true in the automotive industry, where reducing weight can improve fuel efficiency, acceleration, and overall performance. One material that has gained significant attention in recent years is carbon fiber.

Carbon fiber is a material that has long been revered for its high stress-resistance and lightweight properties. Compared to steel, it offers greater strength and durability, which makes it a desirable choice for many applications, especially in the automotive industry.

Although they are more expensive to manufacture, the prices can come down in mass-production settings. With the technology advancing, it was only a matter of time before carbon fiber found its way into engine blocks, and Nissan has already patented a carbon fiber engine.

But how does it work, and what are the benefits and downsides of using carbon fiber for engine blocks?

Well Nissan's patent describes the engine block as having a main block that includes the cylinders, while a resin outer member is welded to it. The outer carbon fiber acts as an insulator from the heat generated by the cylinders, with gaps between the main block and outer carbon fiber becoming water passages.

However, the block isn't entirely made of carbon fiber, as it still uses steel cylinder liners that the carbon fiber holds in place. While this initial design shows promise, it's uncertain if an entire engine block could be made of carbon fiber.

Now you might be thinking if it is so great why hasn’t this been done years ago, well there are some Downsides when using Carbon Fiber for Engine Blocks

And One significant downside of using carbon fiber for engine blocks is its thermal resistance. While the carbon fiber itself can take a significant amount of heat, the resins used in manufacturing it can only withstand temperatures of around 250 degrees Fahrenheit. And This is why the design includes steel cylinder liners, as they can handle the heat generated by piston friction.

Another issue with carbon fiber is its vulnerability to oil, anti-freeze, and fuel. These fluids can potentially attack the resin, causing delamination of the carbon fiber matte. Again not ideal, and if you have ever worked on an engine you would know, most engines have some oil on the block, wheiter it be from work done, or gaskets starting to fail. It is really difficult to keep an enigne super clean

That said using carbon fiber as the main material in an engine block also has some great advanatages

You see Despite the downsides, Carbon fiber blocks are still really good. You see carbon fiber has a lower thermal conductivity, than steel or aluminium, which means more combustion energy is kept in the cylinder. Carbon fiber also has a higher strength-to-weight ratio, which means that it can provide the same durability as an iron block while being much lighter. And with engines lightness is king, you see the lighter the vehicle, the less energy is needed to move it.

Информация по комментариям в разработке