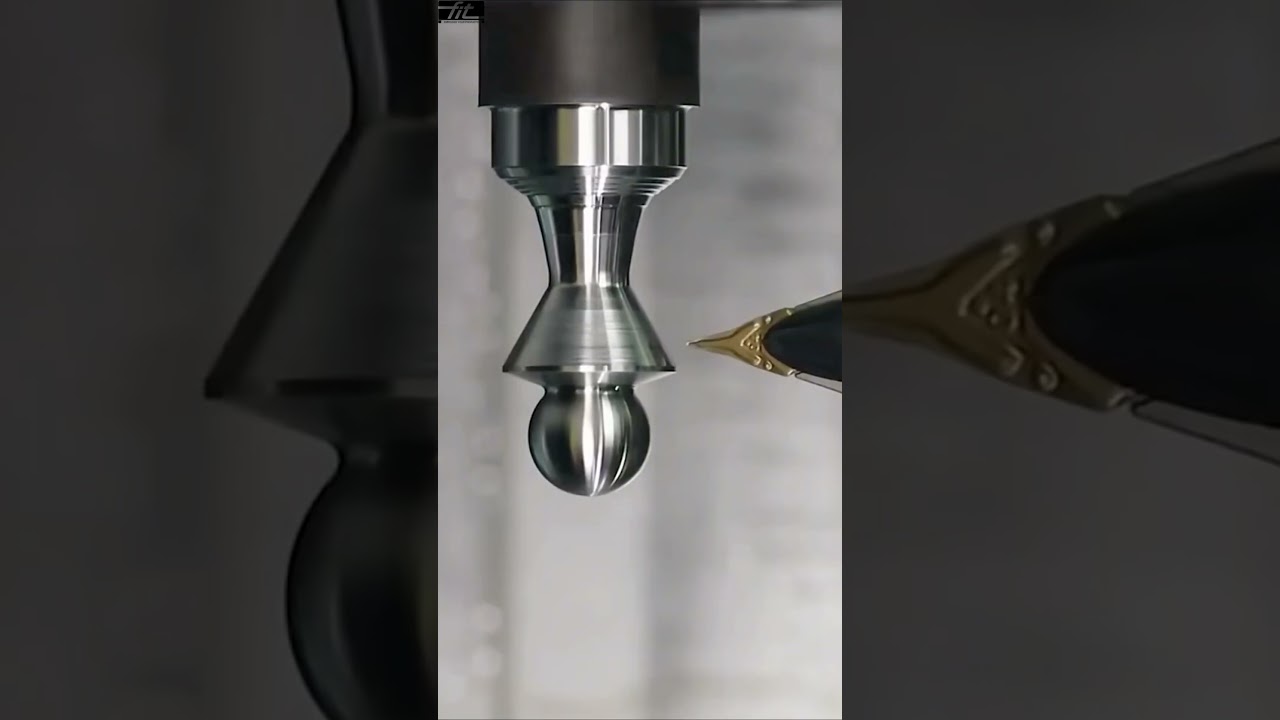

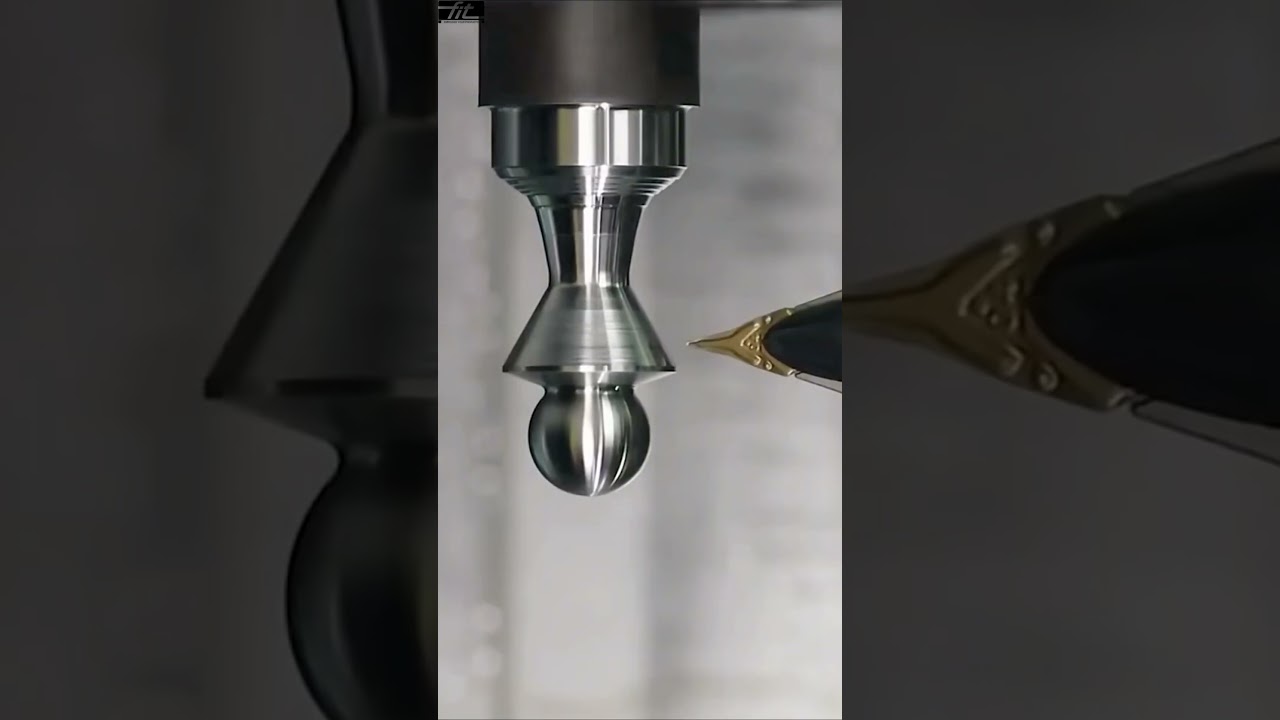

CNC Parts Machining Delivering Precision Components for Modern Manufacturing

Parts machining is one of the most fundamental and essential areas of modern manufacturing, as almost every product relies on accurately produced components to function effectively. Whether in automotive, aerospace, electronics, or industrial equipment, the quality of each part directly determines the performance, durability, and reliability of the final product. This is why CNC machining has become a vital technology for producing high-precision components that meet the increasingly demanding requirements of global industries.

CNC parts machining offers unmatched accuracy, capable of consistently achieving tight tolerances and intricate details that traditional methods struggle to deliver. By combining advanced computer control with high-performance cutting tools, CNC systems ensure that each part is machined to exact specifications, minimizing deviations and guaranteeing repeatability across every batch. This level of consistency is essential for industries where precision is non-negotiable.

Another key advantage of CNC machining in parts production is its efficiency. Automated processes reduce the need for manual intervention, allowing multiple operations to be completed with speed and precision. This not only shortens production time but also reduces waste, improving cost-effectiveness while maintaining high standards of quality. As a result, CNC machining provides an ideal balance of speed, flexibility, and accuracy, enabling manufacturers to respond quickly to market demands.

Durability and performance are also central to machined parts. CNC machining supports a wide range of materials, including aluminum, steel, titanium, and advanced composites. These materials can be shaped with exceptional precision, resulting in parts that not only fit perfectly but also deliver strength and resilience in demanding applications. From structural components in vehicles to small intricate parts in electronics, CNC machining ensures that each piece performs reliably under real-world conditions.

Flexibility is another strength of CNC machining. Whether the requirement is a single prototype or large-scale production, CNC systems adapt to meet different demands without sacrificing quality. This makes it possible to test new designs quickly, optimize product development cycles, and then move seamlessly into high-volume production. The ability to handle diverse geometries and complex designs makes CNC machining indispensable for modern engineering and product innovation.

Quality assurance plays a central role in CNC parts machining. Through advanced inspection techniques and rigorous process control, manufacturers can verify that every part meets stringent specifications before it reaches the customer. This attention to detail ensures consistent performance, reduces the risk of errors, and builds trust in the reliability of CNC-produced components.

In today’s competitive manufacturing landscape, CNC parts machining provides the accuracy, speed, and dependability needed to meet evolving industrial challenges. It is the foundation for creating components that power modern technology, drive innovation, and deliver long-term value. By combining advanced machinery with skilled expertise, CNC machining continues to set the standard for precision engineering in parts production.

learn more:

Official Website:https://www.fitmold.com/

YouTube: / @fitmold

Facebook:https://www.facebook.com/fitmoldtooling/

Twitter:https://twitter.com/fitmoldtooling

LinkedIn:https://www.linkedin.com/company/fit-preci...

Tiktok:https://www.tiktok.com/@fitmold?lang=zh-Ha...

#CNCmachining #partsmachining #precisionengineering #manufacturing #customparts #engineering #production #machiningservices #highquality #technology

Информация по комментариям в разработке