Cordless impact drivers are taking over the market from traditional drill drivers. Why? Because they are easy and quick to work with, and once a professional has experienced the ease with which he can complete screw-driving tasks it becomes habit to continue to do so.

However, as impact drivers have got more and more powerful, with the latest 18V and 24V models being able to exert more than 180Nm of torque in such an aggressive manner, bits and holders were unable to cope. This meant using up vast quantities of screwdriver bit, with bits breaking on even their third and fourth jobs. The longest lasting bit system on the market was the Wera BiTorsion ranges, but even they began to struggle with the very latest impact driver models.

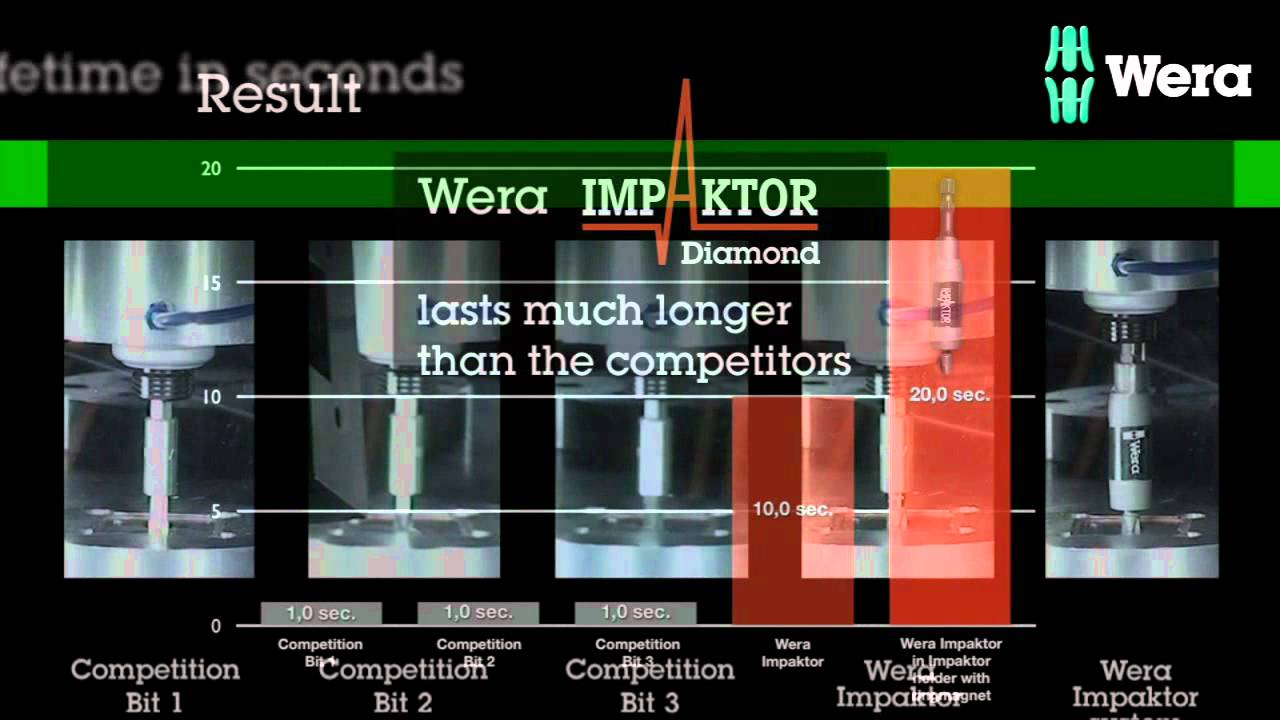

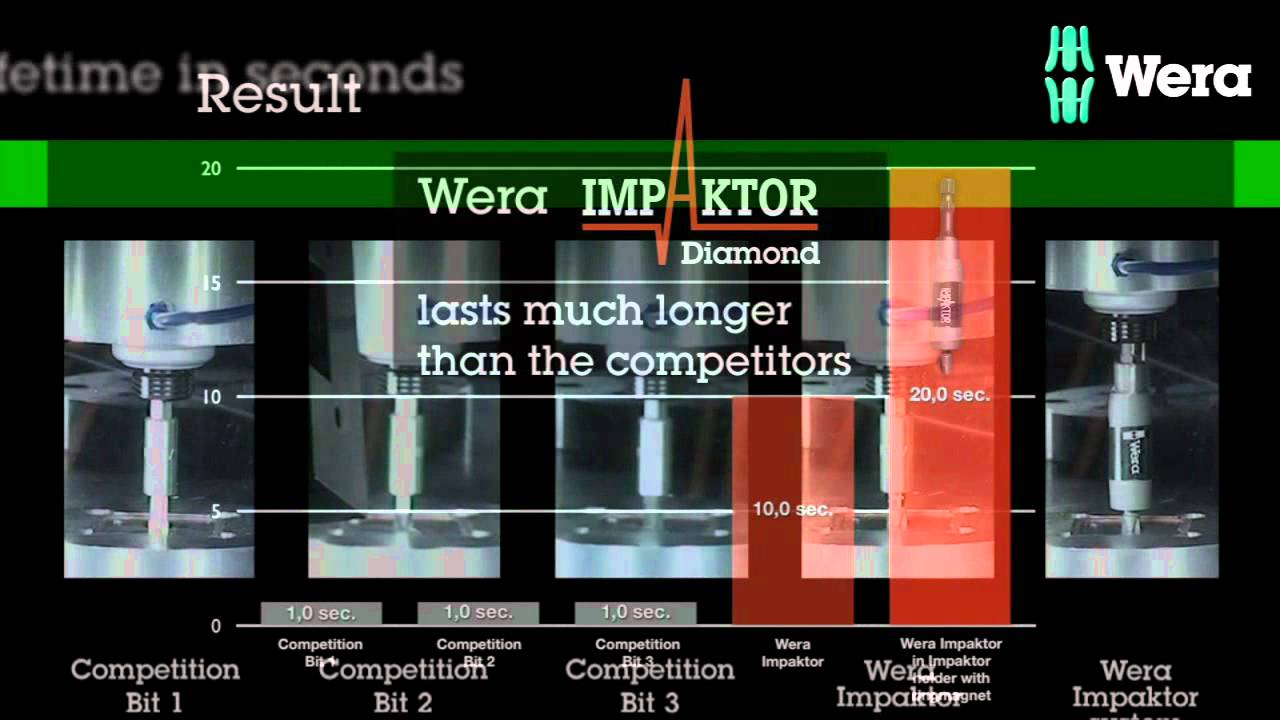

So, at Wera we developed an entirely new system - the IMPAKTOR bit system for cordless impact drivers. If the full system is used, i.e. both bit and holder, you can get up to 10x longer life than the nearest competitor...and that nearest competitor is another Wera product, i.e. the old BiTorsion range! That demonstrates just how tough this new IMPAKTOR range is.

But why does it last so long? Well, it is a combination of several factors:

The bit is precisely machined so it is exactly the right size and shape. This means it sits perfectly in the screwhead, helping prevent movement which ends in slips out of the screwhead

The bits are custom manufactured - each type and size of bit is manufactured in exactly the best way for that bit. For example, it might be better to make a PZ3 bit in a different way to a a Torx 25. This custom bit manufacture is unique to Wera.

Along with perfectly shaped, custom manufactured bits, IMPAKTOR bits also feature diamond coating, which literally 'bites' into the screwhead, further ensuring there is no movement - and it is movement that ends in slips or in bit breakage.

Additionally to all the above, the bits are both manufactured out of the toughest, most ideal steel, and include 2 Torsion zones. These Torsion zones direct the torque away from the tip of the bit, absorbing the rough, aggressive action of the impact driver.

There is also a Torsion zone in the bit holder. These three Torsion zones combine to create the unique TriTorsion system, and ensure unbeatable bit service life. The zones come into action at different times, depending on the material being screwed into and the type of bit/screw. For the most demanding, high torque applications, all three zones will kick in and protect the bit tip - this technology is unique to Wera.

One of the IMPAKTOR bit holders also features a powerful ring magnet, which securely grips up to a 10" screw, both allowing single hand screwdriving and helping to keep the bit firmly seated in the screw. This screw-holding function can be disabled easily to allow screws to be recessed. (The other IMPAKTOR bit holder features an all-stainless steel body and no screw-holding function, and is ideal for production line machinery)

IMPAKTOR bits come in both 25mm and 50mm direct drive variants, across Pozidriv, Phillips, Torx, Hex and Square profiles, and are available individually, in boxes of 10 (25mm) or 5 (50mm) bits, or in 10pc Bit-Check bit sets with the Ringmagnet holder. 50mm bits are also available in 6pc Mini-Check bit sets.

For more details, and a list of stockists who keep the full IMPAKTOR range in stock, see www.impaktor.com, or call 01246 277756

Информация по комментариям в разработке