"A secure knot holds not just rope, but the trust of everyone who relies on it."

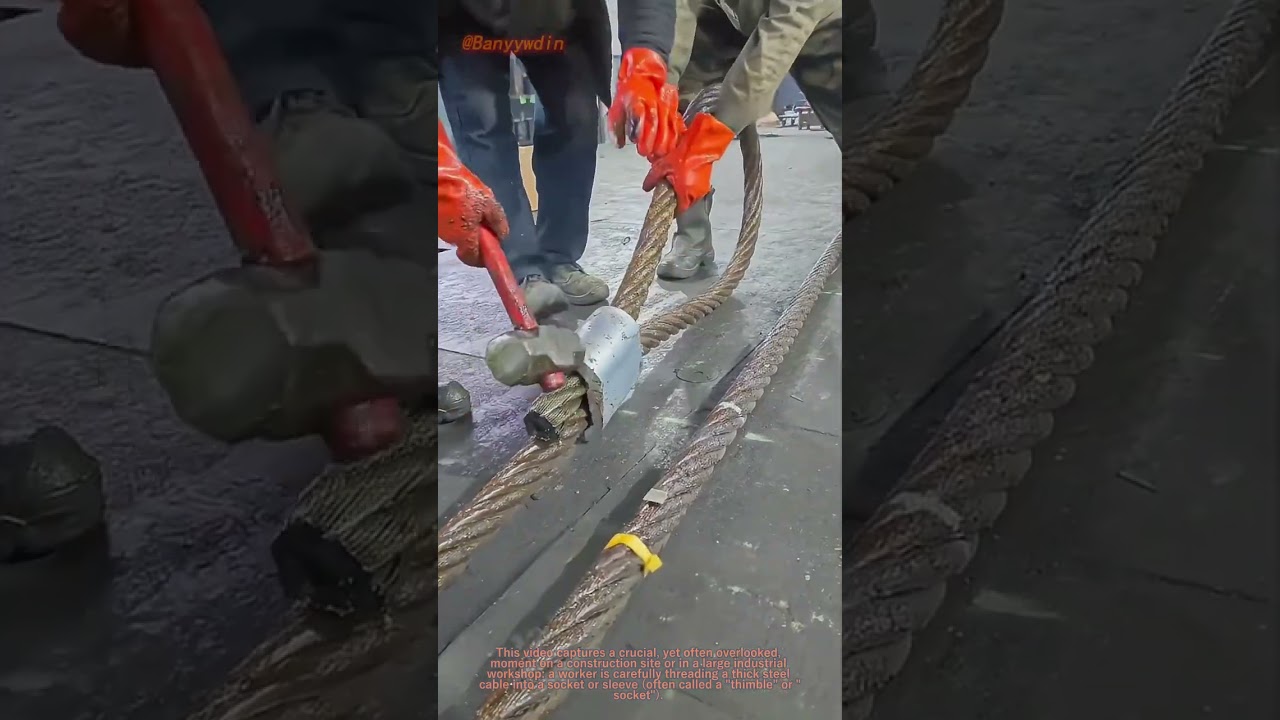

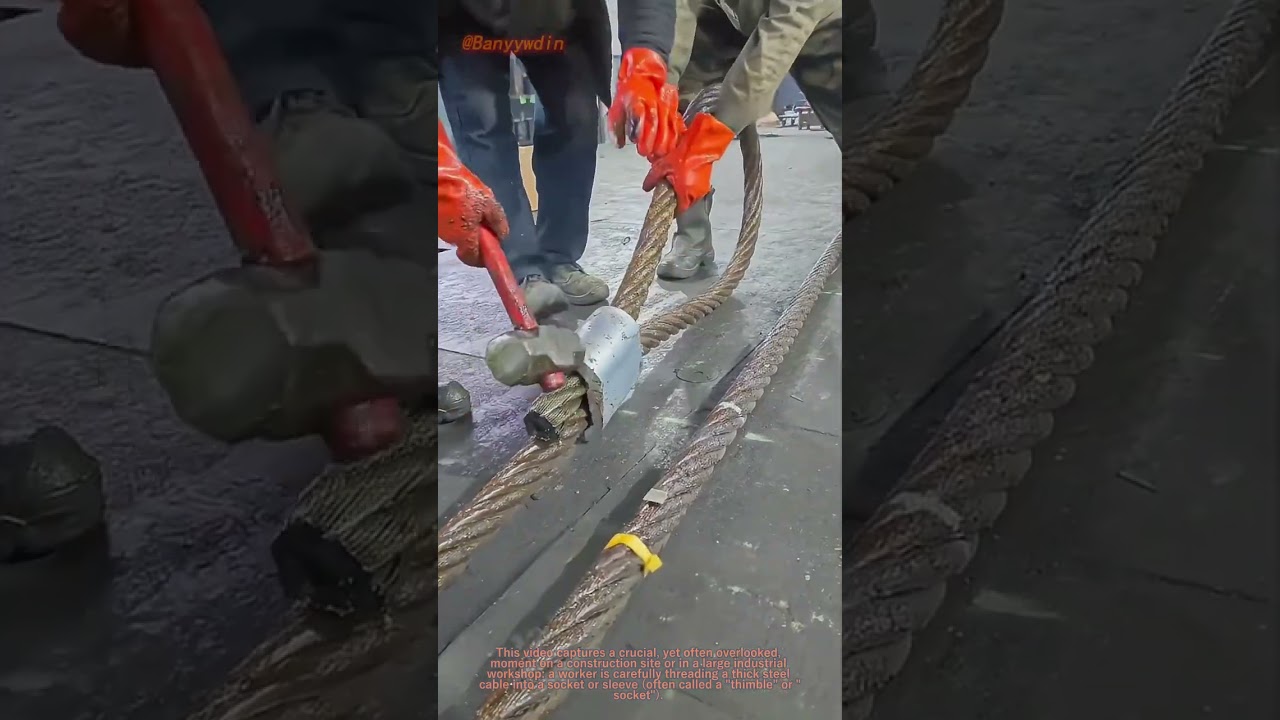

This video captures a crucial, yet often overlooked, moment on a construction site or in a large industrial workshop: a worker is carefully threading a thick steel cable into a socket or sleeve (often called a "thimble" or "socket"). The challenge is universal—how do you securely terminate a flexible steel cable so it can handle immense pulling forces without fraying, slipping, or failing catastrophically? This is the foundational step for countless applications, from supporting overhead lighting and machinery to creating lifting slings and securing loads.

The method demonstrated is beautifully simple and profoundly practical. It often involves preparing the cable end, inserting it into a metal socket (like a), and then securing it. One common and highly effective technique is the "socketing" or "splicing" method. First, the end of the steel cable is "cleaned" by cutting it neatly and sometimes fraying the strands slightly. Then, it is fed into the conical cavity of a metal socket. The true ingenuity lies in the next step: the socket is often filled with a molten metal alloy (like zinc) or a special resin. As this filler cools and solidifies, it grips every individual wire strand inside the socket, creating a monolithic, incredibly strong mechanical lock. The principle is simple: transform a bundle of flexible wires into a solid, anchored mass. Alternatively, for some applications, a mechanical method using specialized clamps (钢索卡 or wire rope clips) is used, where the cable is looped back and clamped onto itself. Both methods prioritize a direct, physical interlock over complex mechanisms.

Why is this simple technique so vital? First, it delivers unmatched strength and reliability. A properly socketed connection can achieve over 90% of the cable's original breaking strength, ensuring safety under heavy loads. Second, it offers significant cost and time efficiency. Compared to welding or using complex proprietary connectors, this method uses relatively inexpensive, standardized components (sockets, filler metal) and can be performed on-site with basic heating equipment (for molten metal) or simple tools (for clamping). Third, it provides superior durability and maintenance. The sealed socket protects the vulnerable cable end from corrosion, dirt, and wear, dramatically extending the life of the entire assembly. This makes it perfect for permanent or long-term installations like factory lighting supports, bridge cables, or securing fixed structures.

Key considerations are essential for success and safety. Preparation is critical: the cable end must be clean and free of grease or damage. The correct socket size and filler material must match the cable diameter and intended load. For molten metal sockets, safety is paramount: handling molten metal requires proper PPE (heat-resistant gloves, face shield) and fire safety measures in a well-ventilated area. The cable must be held perfectly vertical during pouring to ensure the filler flows evenly. For clamp-based methods, the number of clamps and their tightening torque are crucial; usually, at least two clamps are required, and they must be installed with the saddle on the "live" (load-bearing) side of the rope. Most importantly, after installation, the connection should be proof-tested with a load higher than its expected working load before being put into critical service.

This scene is more than just a technical procedure; it embodies the timeless engineering wisdom of solving a critical weakness with elegant simplicity. It proves that by understanding the fundamental properties of materials—turning flexibility into a solid anchor—we can create connections that are not only immensely strong but also beautifully reliable, forming the hidden sinews that hold our built world together.

Информация по комментариям в разработке