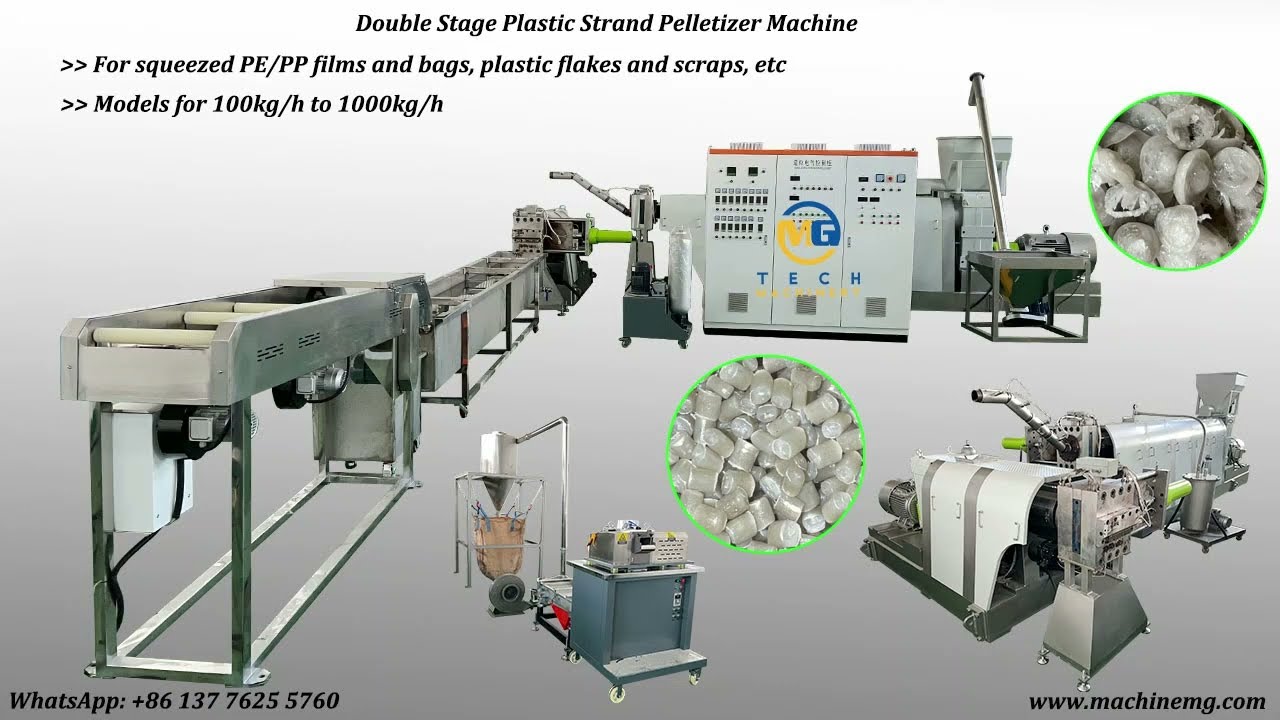

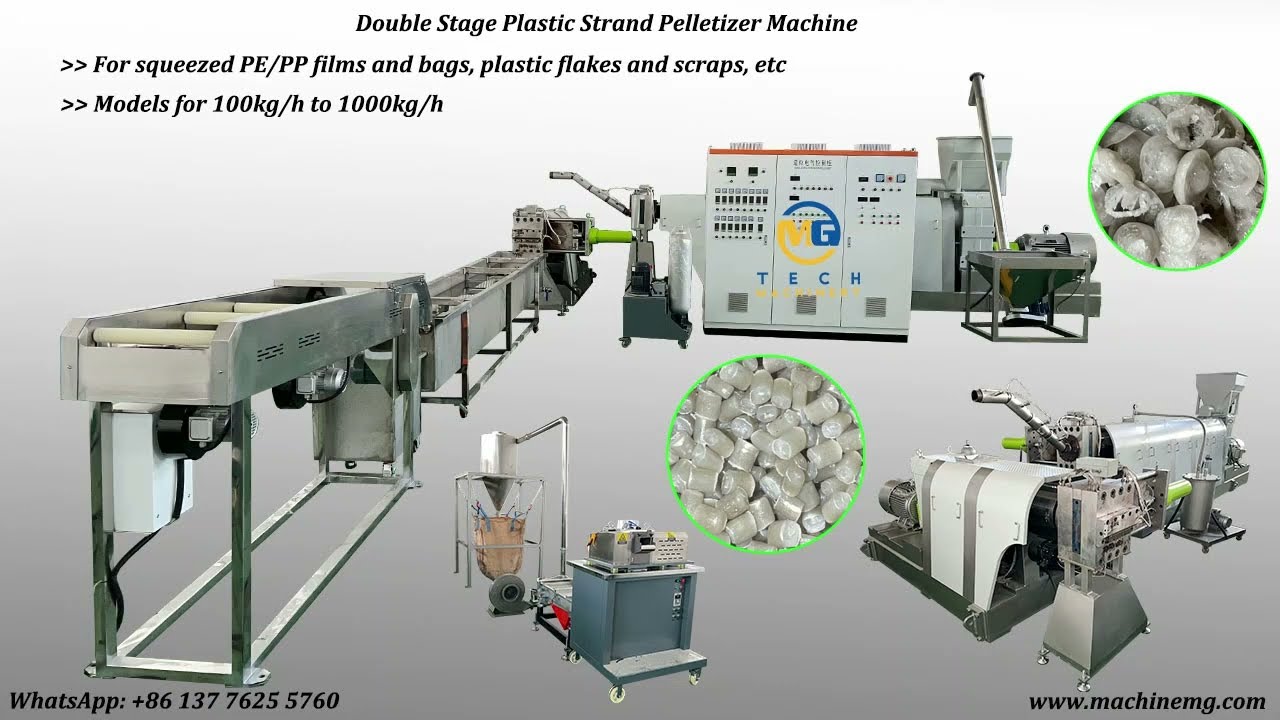

Plastic strand pelletizer line

Plastic strand pelletizer machine is a type of pelletizing equipment used in the plastics industry to convert molten plastic into small and uniform pellets. Unlike water ring pelletizing, which uses water to cool and solidify the plastic before cutting it into pellets, the plastic strand pelletizer forms the plastic into continuous strands, which are then cut into pellets.

Application:

1, plastic flakes or scraps from the plastic crushers, shredder or plastic washing lines, such as PE, PP, PVC, PET, ABS, PS, PC, etc.

2, squeezed PE/PP plastic films and bags.

3, kinds of plastic pellets for modification. Etc.

This video show one double stage plastic strand pelletizer line for making pellets from squeezed PE plastic films.

Consist of:

A plastic strand peleltizer line usually includes the following machines:

1, materials loader: belt conveyor or screw loader are mostly chosen for use, vacuum loader is optional unit.

2, forced feeder: for ration feeding of the plastic materials.

3, extruder: single screw extruder are used mostly for recycling pelletizing, the users can use single stage or double stage even 3 stage extruders for the pelletizing according to the materials conditions and properties.

4, hydraulic screen changer.

5, strand mold

6, water cooling tank with vortex pump for dry the plastic strands.

7, gantry pellet cutter: to cut the plastic strands into pellets.

8, vibration sieve: for pellet classification to get qualified plastic pellets.

9, cyclone silo: for conveying and storing the good pellets.

10, centralized control cabinet: control the working status of the plastic strand pelletizer machine, easy operation and monitoring.

Models of plastic strand pelletizer line in MG machinery company:

We provide different models of the plastic strand pelletizing line for capacity 100kg/h to 1000kg/h.

How a plastic strand pelletizer typically works:

1, Extrusion: The process starts with an extruder, where plastic resin is melted and homogenized under heat and pressure. The molten plastic is forced through a die, which shapes the plastic into continuous strands of a specific diameter.

2, Cooling: As the plastic strands emerge from the die, they are cooled rapidly to solidify them. This cooling process can be achieved using various methods, such as air cooling or water cooling.

3, Strand Pelletizing: Once the plastic strands are sufficiently cooled and solidified, they pass through a gantry type pellet cutter. In this cutter, the rotating blades or knives cut the strands into uniform pellets of the desired length. The pellets are then typically collected in a container or conveyed to further processing equipment.

4, Separation and Classification: After pelletizing, the pellets may undergo additional processing steps, such as separation to remove any fines or oversized pellets. They may also be classified based on size or other properties.

Plastic strand pelletizers are commonly used for a wide range of thermoplastic materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and others. They offer advantages such as high throughput rates, flexibility in pellet size and shape, and relatively simple operation and maintenance compared to other pelletizing methods. They are frequently employed in industries such as plastics recycling, compounding, and polymer production.

If any enquiry or interest, please contact us for the plastic strand pelletizer details and quotation:

Mr.Gram Gao

WhatsApp & WeChat: +86 137 7625 5760

[email protected]

https://www.machinemg.com

Thanks a lot for your time to watch our videos.

Please subscribe our channel for coming videos of new machines.

Информация по комментариям в разработке