"There's an old saying, "Oils ain't oils." I reckon you can also apply that to "Lubes ain't lubes," particularly when we're talking about the proper installation of suspension bushings. Now, I think it's a fair bit to say there's been plenty of instances where perhaps the right procedure hasn't been applied to their fitment. Let's have a closer look at it.

Like any good servicing requirement, of course you should clean the components thoroughly. By "thoroughly," I mean thoroughly. If you don't, you risk shortening the lifetime of the component and you even risk transmitting noise up into the cabin and you don't want to do that. What are some of the key elements to the lubrication of? Well, the first thing you need to do is lubricate the working surfaces.

If we grab any typical bush, I always say to people, "Grab it. Understand how it works. Understand where the clamped force is and where the working or mating parts are, so you only lubricate the inside particularly of that type of bush." If you've got another mating surface, like this bush here, or perhaps even a washer that goes with it, you would lubricate the mating surface.

Don't make the fatal flaw that so many do by not putting any lubricant on at all and just jamming it in there. That's no good at all. We sort of see two extremes in our industry, don't we? We see either people put them in dry or too often coat the whole thing in grease, which is also wrong. You don't want grease on the exterior surfaces of bushes when it's the interior surface that's actually doing the work, so very, very critical.

Up here, we see, again, the application of grease on the exterior. Now, what I really like about the Nolathane product is that's not rubber. If that were rubber, all too often we see coated in rubber grease, so the thing can be compressed and put into situ. Now, that's fine, except it does a couple things, hardens the rubber, because it's being compressed in there, and requires the use of grease where you don't want the grease to be.

What grease do you use? Well, you'll find with every Nolathane product that requires it, it will come with a nice little pack of grease. Now, let me just show you, if I open a little bit of that, get some on my finger, because I want to show you the knurling, that's the right consistency for the application here. If you can see that knurling, which we talked about earlier that holds some of the grease, if I wipe that in there, we're getting close there, you'll see just the right amount of grease in there.

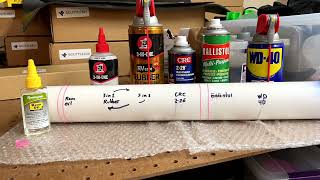

If I could give you some really good advice right now, it would be do not underestimate the importance of proper fitment of suspension bushings and primarily the lubrication thereof. Just recapping, don't use rubber grease. Nolathane products are not rubber. They don't require it. When lubricating, lubricate, identify the mating surfaces, the internal working surfaces, the mating washers, if necessary. Don't lubricate the casing and take note of any other instructions that come with your Nolathane component. I'll steer you in the right direction for optimum and ongoing performance. Head to www.nolathane.com.au

Информация по комментариям в разработке